Are you gearing up for an interview for a Bottle Line Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bottle Line Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

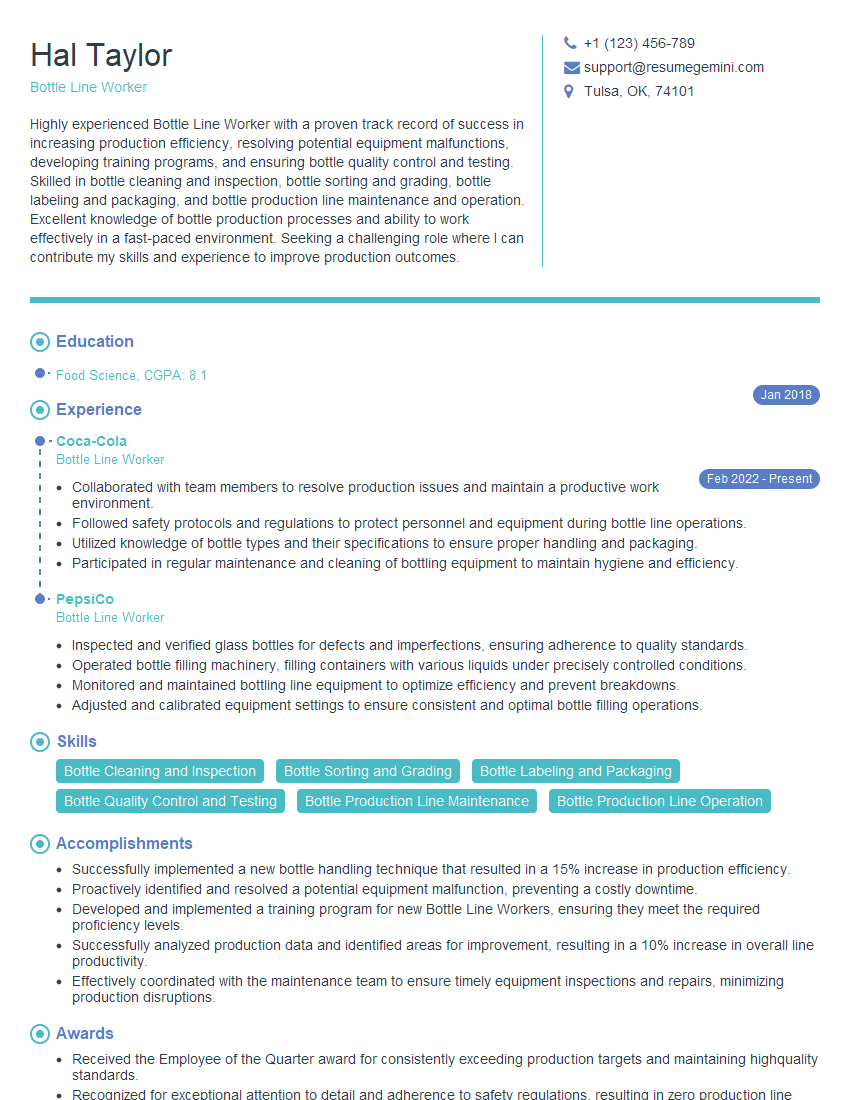

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle Line Worker

1. Describe the process of operating a bottle filling machine?

- Prepare the machine by ensuring it is clean, sanitized, and properly calibrated.

- Load empty bottles onto the conveyor belt.

- Monitor the flow of bottles through the machine, ensuring they are filled to the correct level.

- Inspect bottles for defects or leaks.

- Unload filled bottles from the conveyor belt and pack them for storage or shipment.

2. What are the key safety precautions to follow when working on a bottle filling line?

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including gloves, safety glasses, and earplugs.

Machine Safety

- Never reach into the machine while it is running.

- Report any mechanical issues or malfunctions to a supervisor immediately.

Chemical Safety

- Be aware of the chemicals used in the filling process and follow proper handling procedures.

- Wear appropriate PPE when handling chemicals.

3. How do you troubleshoot common problems that may occur during the bottle filling process?

- Identify the problem by observing the machine’s operation and error messages.

- Refer to the machine’s documentation or consult a supervisor for troubleshooting steps.

- Perform basic troubleshooting steps, such as checking for blockages, loose connections, or incorrect settings.

- If the problem persists, contact a qualified technician for further assistance.

4. What is your experience with maintaining and cleaning bottle filling machines?

- Regularly clean and sanitize all machine components, including the filling nozzles, conveyor belt, and external surfaces.

- Lubricate moving parts as per the manufacturer’s specifications.

- Inspect and replace worn or damaged parts as needed.

- Maintain a log of all maintenance and cleaning activities.

5. How do you ensure the quality of the bottles produced by the filling line?

- Inspect bottles for defects or leaks before and after filling.

- Check the fill level of bottles to ensure it meets specifications.

- Monitor the overall performance of the filling line and identify any areas for improvement.

- Participate in quality assurance programs to maintain product standards.

6. What is your understanding of Good Manufacturing Practices (GMPs) in the beverage industry?

- Adhere to all GMPs related to the production, storage, and handling of beverages.

- Follow proper sanitation procedures to prevent contamination.

- Ensure the proper storage and handling of raw materials and finished products.

- Maintain accurate records and documentation of all production processes.

7. how would you handle a situation where you notice a potential safety hazard on the bottle filling line?

- Immediately identify and assess the potential hazard.

- Take appropriate action to eliminate or mitigate the hazard, such as adjusting machine settings or contacting a supervisor.

- Report the hazard to a supervisor and follow established safety protocols.

- Assist in implementing corrective actions to prevent similar hazards from occurring in the future.

8. What is your experience with working in a fast-paced production environment?

- Demonstrate a strong work ethic and ability to meet production targets.

- Work effectively under pressure and handle multiple tasks simultaneously.

- Maintain a positive attitude and contribute to a productive team environment.

9. How do you stay up-to-date with the latest trends and technologies in the beverage industry?

- Attend industry conferences and trade shows.

- Read industry publications and online resources.

- Network with other professionals in the field.

- Participate in training and development programs.

10. Why are you interested in working as a Bottle Line Worker at our company?

- Express interest in the company’s products, reputation, or mission.

- Highlight the alignment between your skills and the job requirements.

- Demonstrate enthusiasm for the industry and a desire to contribute to the team.

- Explain how the role fits into your career goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle Line Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle Line Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottle Line Workers are responsible for ensuring the smooth functioning of the production line in bottling factories. They perform tasks such as monitoring the equipment, inspecting bottles, and maintaining the cleanliness of the work area.

1. Monitoring the equipment

Bottle Line Workers closely monitor the equipment used in the production line to ensure that it is operating properly. They check for any signs of wear or damage, and they make sure that the equipment is clean and well-maintained.

- Inspecting the equipment for any signs of wear or damage.

- Cleaning and lubricating the equipment as needed.

- Reporting any problems with the equipment to their supervisor.

2. Inspecting bottles

Inspecting bottles for any defects is an important part of the Bottle Line Worker’s job. They look for cracks, chips, or other imperfections that could compromise the integrity of the bottle.

- Inspecting bottles for any defects.

- Rejecting any bottles that do not meet quality standards.

3. Maintaining the cleanliness of the work area

Bottle Line Workers are responsible for maintaining the cleanliness of their work area. They sweep and mop the floors, clean the equipment, and dispose of any waste materials.

- Sweeping and mopping the floors.

- Cleaning the equipment.

- Disposing of any waste materials.

4. Other duties

Bottle Line Workers may also be required to perform other duties, such as:

- Assisting with the loading and unloading of equipment.

- Assisting with the packaging and shipping of products.

- Performing other tasks as assigned by their supervisor.

Interview Tips

Here are some tips to help you ace your interview for a Bottle Line Worker position:

1. Research the company

Take some time to learn about the company you’re interviewing with. This will help you understand their business, their culture, and their values.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked. Practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience working in a bottling factory. Be prepared to talk about your responsibilities, your accomplishments, and your skills.

- Use the STAR method to answer interview questions.

- Highlight your transferable skills.

- Be enthusiastic and positive about your experience.

4. Dress professionally

First impressions matter. Dress professionally for your interview to show the interviewer that you’re serious about the position.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing strong perfumes or colognes.

5. Be on time

Punctuality is important. Arrive for your interview on time to show the interviewer that you’re respectful of their time.

- Plan your route ahead of time.

- Give yourself plenty of time to travel.

- Arrive 10-15 minutes early for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottle Line Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.