Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Canning Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Canning Machine Operator so you can tailor your answers to impress potential employers.

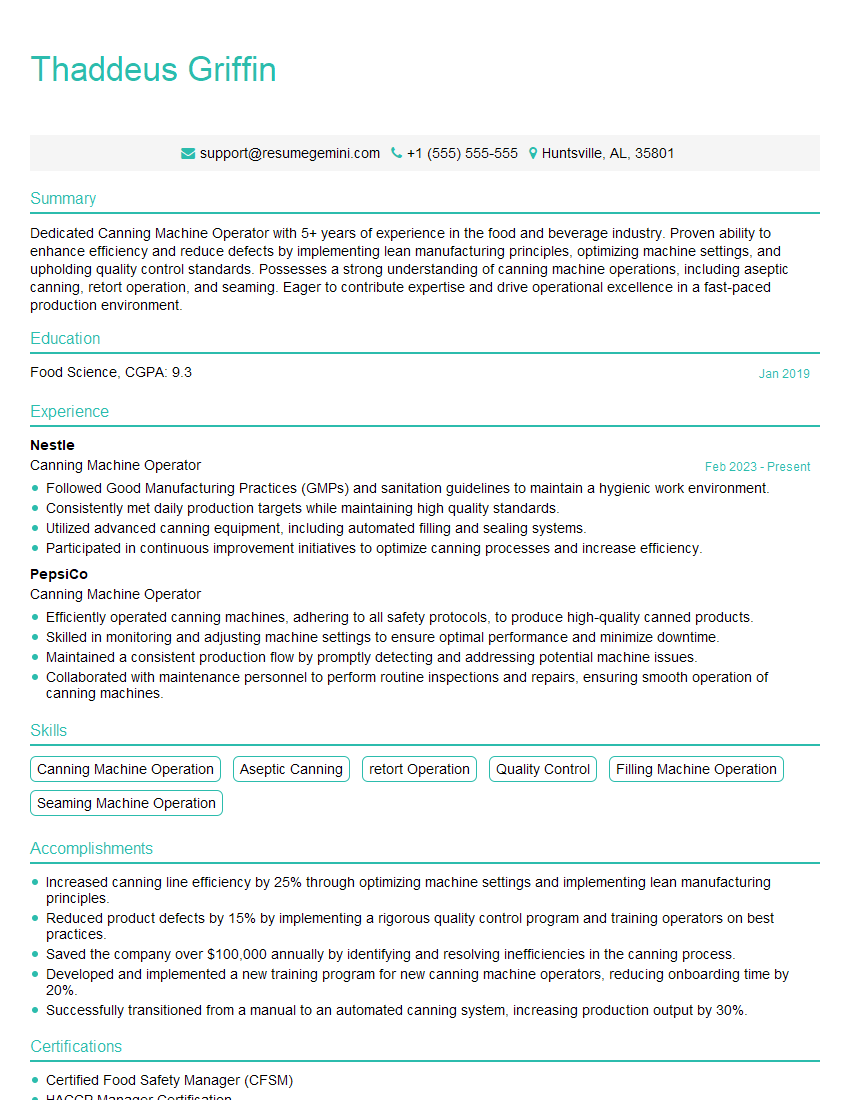

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Canning Machine Operator

1. Describe the process of operating a canning machine.

The process of operating a canning machine involves several key steps:

- Can Preparation: Preparing the cans by ensuring they are clean, free of dents, and properly aligned on the conveyor belt.

- Product Loading: Filling the cans with the desired product using automated filling systems or manually.

- Can Sealing: Sealing the cans using specialized equipment to create an airtight seal, preventing contamination and spoilage.

- Can Cooling: Cooling the sealed cans through a cooling tunnel or water bath to stabilize the product and prevent expansion.

- Labeling and Coding: Applying labels and printing essential information, such as product details, ingredients, and manufacturing dates.

- Packaging and Palletizing: Arranging the labeled cans into cases, cartons, or shrink-wrapped packs for transportation and storage.

2. Explain the safety precautions required while operating a canning machine.

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including protective gloves, safety glasses, earplugs, and a hairnet.

- Ensure proper ventilation and follow all safety guidelines.

Machine Operation

- Inspect the machine regularly for any potential hazards or malfunctions.

- Never attempt to operate the machine without proper training and authorization.

- Keep hands and loose clothing away from moving parts.

Emergency Procedures

- Know the location of emergency shut-off switches and follow proper evacuation procedures.

- Report any accidents or incidents immediately to the supervisor.

3. How do you maintain and troubleshoot a canning machine?

Regular maintenance and troubleshooting are essential for the efficient operation of a canning machine. Here are some key tasks:

- Daily Inspections: Conduct daily inspections to identify any potential issues, such as leaks, loose parts, or unusual noises.

- Regular Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to reduce friction and prevent wear.

- Sensor Calibration: Calibrate sensors regularly to ensure accurate filling, sealing, and labeling.

- Troubleshooting Common Issues: Address common issues such as can jams, product leaks, or label misalignment promptly. Refer to technical manuals or consult with experienced technicians for assistance.

- Record Keeping: Maintain detailed records of maintenance activities, including inspections, repairs, and any upgrades or modifications.

4. Explain the principles of sanitation and hygiene in a canning operation.

- Facility Cleanliness: Maintain a clean and organized work environment to prevent contamination.

- Equipment Hygiene: Regularly clean and sanitize all equipment, including canning machines, conveyors, and filling systems.

- Personal Hygiene: Employees must adhere to strict personal hygiene practices, including proper handwashing and wearing clean uniforms.

- Pest Control: Implement effective pest control measures to prevent contamination from insects, rodents, or other pests.

- Water Quality: Ensure the use of clean water for rinsing and cooling to maintain product safety and prevent spoilage.

5. How do you ensure the quality of canned products?

- Raw Material Inspection: Inspect incoming raw materials to ensure they meet quality standards.

- Process Monitoring: Monitor critical process parameters such as filling levels, sealing integrity, and cooling temperatures.

- Product Testing: Conduct regular quality checks on finished products to assess taste, texture, and appearance.

- Traceability: Implement a traceability system to track products throughout the production process, enabling quick identification and recall in case of any quality issues.

- Continuous Improvement: Participate in ongoing quality improvement initiatives to identify and address potential problems.

6. Explain the importance of teamwork in a canning operation.

- Coordination: Effective teamwork ensures smooth coordination between different departments and individuals involved in the canning process.

- Problem Solving: Collaborative problem-solving helps identify and resolve issues quickly, minimizing downtime and maintaining production efficiency.

- Safety: Teamwork promotes a safe work environment by sharing knowledge, monitoring each other’s actions, and responding promptly to potential hazards.

- Quality Assurance: Collective efforts contribute to maintaining high-quality standards throughout the canning operation.

- Continuous Improvement: Open communication and teamwork facilitate continuous improvement by sharing ideas and best practices.

7. Describe your experience in handling and resolving production challenges.

In my previous role as a Canning Machine Operator, I encountered various production challenges and developed effective strategies to resolve them. Some notable examples include:

- Canning Machine Malfunction: I quickly identified and repaired a malfunctioning valve that was causing production delays.

- Raw Material Shortage: I collaborated with the procurement team to find an alternative supplier and ensure uninterrupted production.

- Product Quality Issue: I investigated a complaint regarding product texture and traced the issue to improper cooling temperatures. I adjusted the cooling system to resolve the problem.

- Labeling Error: I detected and corrected a labeling error that could have resulted in a product recall. I implemented a double-checking procedure to prevent similar errors in the future.

8. How do you stay updated on industry best practices and technological advancements in canning?

- Attending Conferences and Seminars: I regularly attend industry events to learn about new techniques and technologies.

- Reading Trade Publications: I subscribe to trade magazines and journals to stay informed about current industry trends.

- Networking with Professionals: I connect with other canning professionals at conferences and online forums to share knowledge and learn from their experiences.

- Manufacturer Training: I participate in training programs offered by equipment manufacturers to stay proficient in operating and maintaining canning machinery.

- Continuous Learning: I am committed to continuous learning and seek opportunities to expand my knowledge and skills in the canning industry.

9. How do you prioritize tasks and manage your time effectively in a fast-paced canning environment?

- Daily Planning: I start each day by prioritizing tasks based on urgency and importance.

- Time Blocking: I allocate specific time slots for different tasks to maintain focus and avoid distractions.

- Delegation: I delegate tasks to other team members when appropriate to optimize productivity.

- Flexible Schedule: I am willing to adjust my schedule as needed to meet production demands and unforeseen circumstances.

- Continuous Improvement: I regularly review my time management strategies and identify areas for improvement.

10. Why are you interested in working as a Canning Machine Operator in our company?

I am eager to join your esteemed company as a Canning Machine Operator because:

- Industry Reputation: Your company is renowned in the industry for its commitment to quality and innovation.

- Advanced Technology: I am impressed by your investment in state-of-the-art canning machinery, which aligns with my desire to work with the latest technology.

- Growth Opportunities: I believe that your company provides a supportive environment for professional growth and advancement.

- Contribution: I am confident that my skills and experience in canning operations can contribute positively to your team and help drive success.

- Long-Term Career: I am seeking a long-term career in the canning industry, and I believe that your company offers the stability and opportunities I need to achieve my goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Canning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Canning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Canning Machine Operators play a crucial role in the food and beverage industry, ensuring that products are safely and efficiently canned for consumption. Their key responsibilities include:

1. Operating and Monitoring Canning Machines

Operators are responsible for setting up, operating, and monitoring canning machines to ensure they function smoothly and produce consistent results. They adjust machine settings such as speed, temperature, and pressure to meet product specifications.

2. Loading and Unloading Cans

Operators load empty cans onto the machine and unload filled cans. They may also inspect cans for defects or damage before and after processing.

3. Product Inspection

Operators visually inspect products during the canning process to ensure they meet quality standards. They check for proper fill levels, seal integrity, and any visible defects.

4. Line Maintenance

To prevent disruptions, operators perform basic maintenance tasks on the canning line. They clean equipment, replace filters, and lubricate moving parts.

5. Quality Assurance

Operators adhere to food safety and quality control procedures to ensure products meet industry standards. They may participate in quality audits or inspections.

Interview Tips

To ace the interview for a Canning Machine Operator position, candidates should focus on highlighting their technical skills, experience, and attention to detail. Here are some tips:

1. Technical Skills

Emphasize your expertise in operating and maintaining canning machines. Provide specific examples of how you have successfully adjusted machine settings to optimize production or resolved technical issues.

2. Experience

Quantify your experience with clear metrics. Mention the number of cans you have processed, the types of products you have worked with, and any notable achievements or improvements you have made.

3. Attention to Detail

Highlight your keen eye for detail by describing how you have effectively inspected cans and identified defects. Explain the quality control procedures you are familiar with and your commitment to ensuring product safety.

4. Safety and Hygiene

Discuss your knowledge of food safety and hygiene regulations. Describe how you maintain a clean and sanitary work environment and follow proper handling procedures.

5. Communication and Teamwork

Emphasize your ability to communicate effectively with colleagues and supervisors. Describe how you contribute to a team environment and resolve issues in a cooperative manner.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Canning Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Canning Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.