Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Candy Wrapping Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Candy Wrapping Machine Operator so you can tailor your answers to impress potential employers.

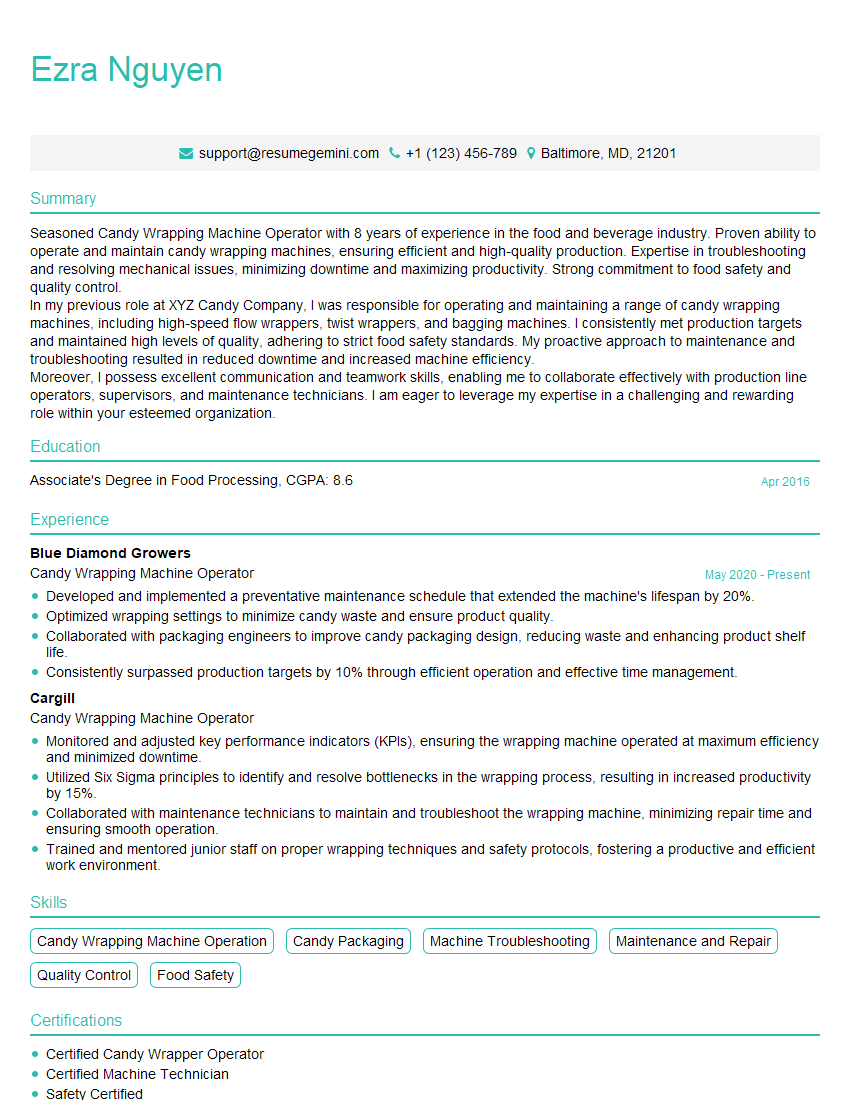

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candy Wrapping Machine Operator

1. Describe the key components of a candy wrapping machine and explain their respective functions.

A typical candy wrapping machine consists of the following components:

- Feeder: This component loads and aligns the unwrapped candies onto the conveyor belt.

- Former: This shapes the wrapping material around the candies, creating the desired shape and size.

- Wrapping Unit: The wrapping unit applies the wrapping material to the candies, sealing it securely.

- Cooling Tunnel: This section of the machine cools the wrapped candies, solidifying the wrapping and preventing them from sticking together.

- Discharge Conveyor: This conveyor belt transports the wrapped candies out of the machine.

2. What are the different types of wrapping materials used for candies, and what are their advantages and disadvantages?

Paper Wrapping

- Advantages: Biodegradable, cost-effective, printable

- Disadvantages: Not moisture-resistant, can tear easily

Plastic Wrapping

- Advantages: Moisture-resistant, durable, flexible

- Disadvantages: Less eco-friendly, can be more expensive

Aluminum Foil

- Advantages: Excellent moisture and light barrier, protects against oxidation

- Disadvantages: Can be expensive, difficult to shape

Laminated Wrapping

- Advantages: Combines the benefits of multiple materials, providing moisture resistance, strength, and printability

- Disadvantages: Can be more complex to manufacture

3. What are the common troubleshooting procedures for candy wrapping machines?

- Misalignment of components: Check and adjust the alignment of the feeder, former, and wrapping unit.

- Broken or damaged parts: Inspect all components for wear and tear, and replace damaged parts promptly.

- Insufficient or excessive heat: Adjust the temperature settings of the former and cooling tunnel as needed.

- Electrical issues: Check the electrical connections, fuses, and switches.

- Contaminated wrapping material: Replace the wrapping material if it becomes contaminated.

4. How do you ensure the quality and consistency of wrapped candies?

- Regular machine maintenance: Perform preventive maintenance inspections to identify and address potential problems.

- Monitoring and adjustment: Observe the wrapped candies throughout the production process and make adjustments to machine settings as needed.

- Quality control checks: Conduct regular quality control checks to verify the size, shape, and wrapping integrity of the candies.

- Training: Ensure that operators are well-trained and understand the machine’s functions and troubleshooting procedures.

- Continuous improvement: Regularly review and improve production processes and documentation.

5. What is the importance of safety when operating a candy wrapping machine?

- Preventing accidents: Following safety protocols helps reduce the risk of injuries, such as cuts, burns, or falls.

- Protecting equipment: Proper handling and operation of the machine prevent damage to components and ensure its longevity.

- Maintaining a clean work environment: Cleaning and sanitizing the machine regularly prevents contamination and promotes overall hygiene.

- Complying with regulations: Safety protocols ensure compliance with occupational health and safety standards.

- Protecting company reputation: A safe work environment fosters employee well-being and reduces the risk of accidents, which can impact the company’s reputation.

6. How do you handle unexpected breakdowns or malfunctions of the candy wrapping machine?

In the event of an unexpected breakdown or malfunction, I would take the following steps:

- Assess the situation: Quickly identify the issue and determine its severity.

- Isolating the problem: Shut down the machine and isolate the affected area to prevent further damage.

- Consulting documentation: Refer to machine manuals or technical diagrams to troubleshoot the issue.

- Attempting repairs: Perform basic repairs or adjustments if possible with the necessary tools and safety precautions.

- Calling for assistance: If the issue cannot be resolved, contact a qualified mechanic or technical support team for assistance.

7. What is the role of automation in the operation of candy wrapping machines?

- Increased efficiency: Automation reduces manual labor and speeds up the wrapping process, resulting in higher production output.

- Improved accuracy: Automated machines ensure consistent and accurate wrapping of candies, reducing the risk of errors.

- Reduced downtime: Automated machines can operate continuously for extended periods, minimizing the need for frequent manual interventions.

- Data collection and analysis: Automated machines can collect and analyze data on machine performance, allowing for optimization and predictive maintenance.

8. How do you stay updated on the latest advancements in candy wrapping technology?

- Industry events and conferences: Attend trade shows and industry events to learn about new technologies and trends.

- Technical publications: Subscribe to industry-related magazines and journals to stay abreast of new developments and best practices.

- Online research: Engage in online research through reputable sources and industry forums to learn about emerging technologies.

- Networking: Connect with professionals in the field and attend industry seminars to gain insights into the latest advancements.

- Training and certification: Consider pursuing additional training or certification programs to expand knowledge and stay updated.

9. What are the different types of candy wrapping machine sensors, and what are their functions?

- Optical sensors: These sensors use light to detect the presence, position, and shape of candies.

- Proximity sensors: These sensors detect the proximity of objects, such as the wrapping material to the candy.

- Temperature sensors: These sensors monitor the temperature of the heating and cooling components of the machine.

- Motion sensors: These sensors detect the movement of the machine’s components, ensuring proper operation.

- Pressure sensors: These sensors measure the pressure of the wrapping material, ensuring it is applied correctly to the candy.

10. How do you ensure food safety and sanitation when operating a candy wrapping machine?

- Cleaning and sanitizing: Regularly clean and sanitize the machine, conveyor belts, and tools to prevent contamination.

- Regular maintenance: Conduct regular maintenance checks to ensure the machine is operating correctly and that all components are in good condition.

- Hand hygiene: Practice good hand hygiene and wear gloves when handling candies to prevent cross-contamination.

- Pest control: Implement pest control measures around the machine to prevent contamination.

- Adhering to regulations: Follow all food safety regulations and protocols.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candy Wrapping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candy Wrapping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Candy Wrapping Machine Operators play a crucial role in the production of wrapped candies. Their primary responsibilities include:

1. Machine Operation and Maintenance

Operate candy wrapping machines to wrap candies efficiently and according to specifications.

- Load and adjust machines as per candy size, shape, and wrapping material.

- Monitor machines for proper functioning and make adjustments as needed.

2. Quality Control

Ensure that wrapped candies meet quality standards.

- Inspect wrapped candies for defects, missing labels, or other issues.

- Report any quality concerns to supervisors and take corrective actions.

3. Production Support

Assist in maintaining a safe and efficient work environment.

- Clean and sanitize machines and work areas.

- Order and maintain supplies, such as wrapping materials and labels.

4. Team Collaboration

Work effectively as part of a team.

- Communicate with other operators and supervisors to coordinate production.

- Assist with training new employees and providing support.

Interview Tips

To ace the interview for a Candy Wrapping Machine Operator position, candidates should focus on highlighting their skills and experience relevant to the job’s responsibilities.

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and values.

- Review the job description carefully to understand the specific requirements.

- Prepare questions that demonstrate your interest and understanding of the role.

2. Emphasize Experience and Skills

Highlight your experience operating candy wrapping machines.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Describe your ability to identify and resolve machine issues.

- Showcase your attention to detail and commitment to quality control.

3. Demonstrate Teamwork and Communication

Candy Wrapping Machine Operators often work as part of a team.

- Provide examples of your ability to collaborate with others effectively.

- Describe your communication skills and how you resolve conflicts.

- Highlight your willingness to help train and support new team members.

4. Be Prepared for Technical Questions

Interviewers may ask technical questions about candy wrapping machines.

- Prepare for questions about different types of machines.

- Be ready to discuss troubleshooting techniques.

- Practice answering questions about machine maintenance and safety procedures.

5. Practice and Follow Up

Practice answering common interview questions beforehand.

- Ask for a copy of the interview questions, if available, and prepare responses.

- Follow up with the interviewer after the interview to thank them for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Candy Wrapping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.