Are you gearing up for a career in Carton Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Carton Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

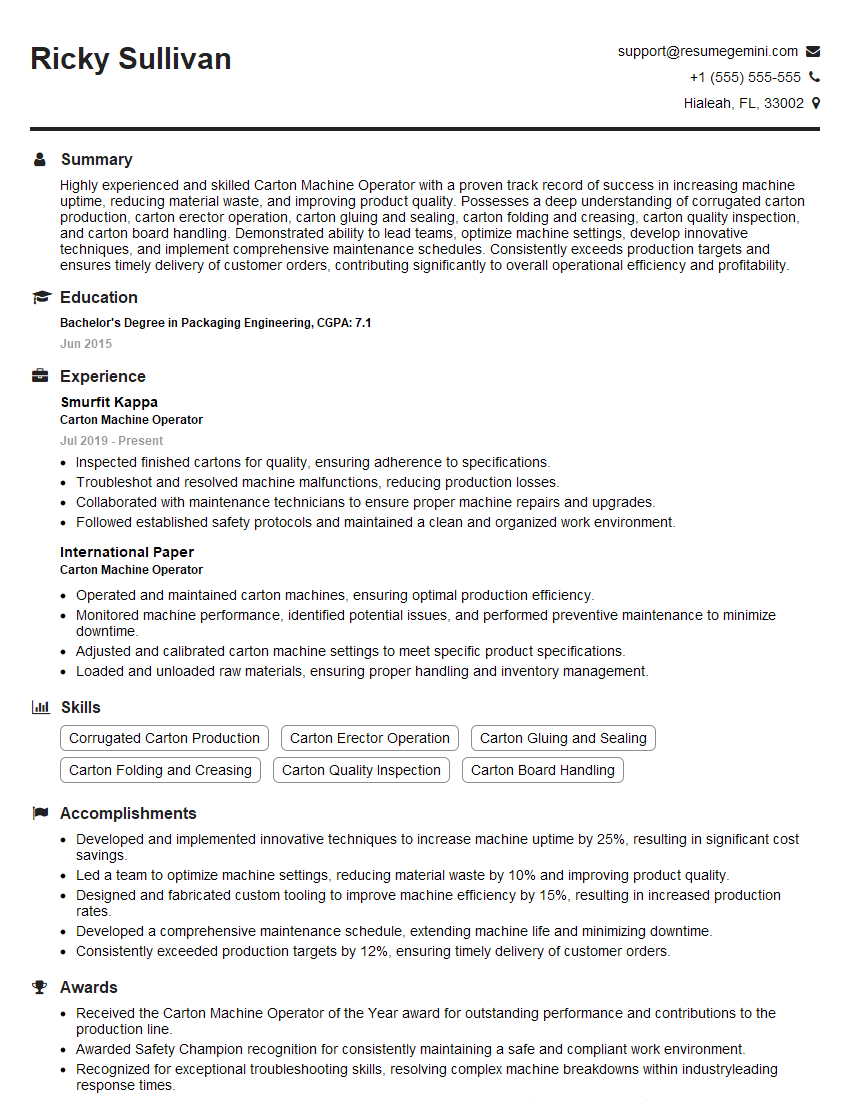

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carton Machine Operator

1. Explain the process of setting up a carton machine for a new production run?

The process of setting up a carton machine for a new production run involves several key steps:

- Prepare the machine: Ensure the machine is clean, lubricated, and in good working condition.

- Load the raw materials: Feed the machine with the required paperboard and adhesive.

- Adjust machine settings: Calibrate the machine’s settings based on the carton specifications, including dimensions, folding patterns, and gluing parameters.

- Run test cartons: Produce a small batch of cartons to verify the setup and make any necessary adjustments.

- Monitor and optimize production: Once the setup is complete, closely monitor the production process to ensure smooth operation and make adjustments as needed to optimize production efficiency and quality.

2. Describe the different types of carton materials and their properties?

Paperboard

- Made from recycled paper or virgin wood fibers.

- Available in various grades with different thicknesses and strengths.

- Can be coated or treated to enhance its properties.

Corrugated cardboard

- Consists of multiple layers of paperboard with a wavy layer in between.

- Provides excellent cushioning and protection properties.

- Used for heavy-duty packaging.

Plastic

- Durable and resistant to moisture and chemicals.

- Can be transparent or opaque.

- Used for food, beverage, and cosmetic packaging.

3. Explain how to troubleshoot common problems with a carton machine?

Troubleshooting common problems with a carton machine involves a systematic approach:

- Identify the problem: Observe the symptoms and note any unusual noises, vibrations, or errors.

- Inspect the machine: Examine the machine’s components, including the paper feed, gluing system, and folding mechanisms.

- Review the settings: Ensure the machine’s settings are correct for the current production run.

- Check the materials: Verify the quality and specifications of the paperboard and adhesive being used.

- Refer to maintenance manuals: Consult the manufacturer’s maintenance manuals for specific troubleshooting procedures and solutions.

4. How to ensure the quality of the produced cartons?

Ensuring the quality of the produced cartons involves several measures:

- Regular maintenance: Perform routine maintenance tasks to keep the machine in optimal condition.

- Quality control: Inspect the cartons throughout the production process to ensure they meet specifications.

- Use high-quality materials: Utilize paperboard and adhesive that meet industry standards.

- Calibrate equipment: Regularly calibrate the machine’s sensors and measuring devices to ensure accuracy.

- Train operators: Provide thorough training to operators on proper machine operation and quality control procedures.

5. Describe the importance of safety practices in the operation of a carton machine?

Safety practices in the operation of a carton machine are crucial to prevent accidents and injuries:

- Wear appropriate PPE: Utilize safety glasses, gloves, and hearing protection as required.

- Follow lockout/tagout procedures: Isolate and de-energize the machine before performing maintenance or repairs.

- Be aware of pinch points: Identify and avoid areas where fingers or limbs could be caught.

- Keep the work area clean: Remove debris and tripping hazards to maintain a safe environment.

- Report any safety concerns: Immediately report any unsafe conditions or equipment malfunctions to supervisors.

6. How to improve the efficiency of a carton machine?

Improving the efficiency of a carton machine involves several strategies:

- Optimize machine settings: Calibrate the machine to minimize downtime and maximize production speed.

- Automate processes: Utilize automated equipment for tasks such as loading and unloading cartons.

- Reduce setup times: Streamline setup procedures to minimize changeover time between production runs.

- Perform regular maintenance: Keep the machine well-maintained to prevent breakdowns and ensure smooth operation.

- Train operators: Provide training to operators on efficient operating techniques and troubleshooting procedures.

7. How to handle a production line malfunction or breakdown?

Handling a production line malfunction or breakdown involves the following steps:

- Identify the problem: Quickly identify the source of the malfunction or breakdown.

- Isolate the affected area: Disconnect the affected machine or equipment from the production line to prevent further damage.

- Assess the situation: Determine the extent of the problem and estimate the repair time.

- Notify supervisors: Inform supervisors of the situation and request assistance if necessary.

- Repair or replace: Depending on the severity of the problem, repair or replace the affected component or equipment.

8. How to work effectively in a production line environment?

Working effectively in a production line environment requires:

- Attention to detail: Pay close attention to instructions and follow procedures to ensure the production of high-quality cartons.

- Teamwork: Collaborate effectively with other operators to maintain a smooth workflow.

- Adaptability: Be flexible and adaptable to changing production demands and schedules.

- Problem-solving skills: Identify and resolve production issues quickly and efficiently.

- Safety awareness: Maintain a safe work environment by adhering to safety protocols and reporting any potential hazards.

9. How to stay updated on the latest advancements in carton machine technology?

To stay updated on the latest advancements in carton machine technology:

- Attend industry events: Participate in conferences, exhibitions, and workshops to learn about new technologies and equipment.

- Read technical publications: Subscribe to industry magazines and journals to stay informed about the latest trends.

- Network with other professionals: Connect with other carton machine operators and engineers to share knowledge and experiences.

- Consult with equipment manufacturers: Reach out to carton machine manufacturers for information about their latest products and innovations.

- Utilize online resources: Explore websites, forums, and social media platforms to access technical articles, case studies, and industry updates.

10. How to improve the overall efficiency of a carton packaging line?

Improving the overall efficiency of a carton packaging line involves various strategies:

- Optimize machine performance: Ensure that all machines are operating at peak efficiency by regular maintenance, calibration, and troubleshooting.

- Streamline production flow: Analyze the production process to identify and eliminate bottlenecks and delays.

- Automate processes: Implement automated equipment for tasks such as carton loading, palletizing, and quality control to reduce manual labor and increase productivity.

- Improve material handling: Optimize the storage, transportation, and handling of cartons throughout the packaging line to minimize waste and damage.

- Train operators: Provide comprehensive training to operators on efficient operating techniques, troubleshooting, and quality control procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carton Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carton Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carton Machine Operators are responsible for ensuring the smooth functioning of carton machines, adhering to quality standards. Their key responsibilities include:

1. Machine Operation

Starting, operating, and monitoring carton machines efficiently.

- Setting up and calibrating machines according to specifications.

- Loading and unloading raw materials and finished products.

2. Quality Control

Inspecting cartons regularly for defects and ensuring they meet quality requirements.

- Conducting routine maintenance and troubleshooting to prevent breakdowns.

- Adhering to safety protocols and maintaining a clean work area.

3. Production Optimization

Monitoring production processes to maximize efficiency and minimize downtime.

- Identifying and implementing process improvements.

- Collaborating with other team members to optimize workflow.

4. Record Keeping and Reporting

Maintaining accurate production records and documenting performance.

- Reporting any malfunctions or issues to supervisors.

- Keeping track of inventory and supplies.

Interview Preparation Tips

To ace the interview, candidates should:

1. Research the Company and Industry

Demonstrate familiarity with the company’s products, values, and industry trends.

- Visit the company website and social media pages.

- Explore industry news and publications.

2. Highlight Relevant Experience

Emphasize relevant skills and experiences that align with the job description.

- Quantify accomplishments using specific metrics when possible.

- Be prepared to discuss challenges faced and lessons learned.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to the industry and role.

- Example Outline:

- Tell me about yourself.

- Why are you interested in this role?

- What are your strengths and weaknesses?

- How do you handle pressure and deadlines?

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates interest and engagement.

- Example Outline:

- What are the biggest challenges facing the company in this industry?

- How do you measure success in this role?

- What opportunities for professional development are available?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately and arrive punctually for the interview.

- Research the company’s dress code.

- Allow ample time for travel and parking.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Carton Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Carton Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.