Are you gearing up for an interview for a Casing Finisher and Stuffer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Casing Finisher and Stuffer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

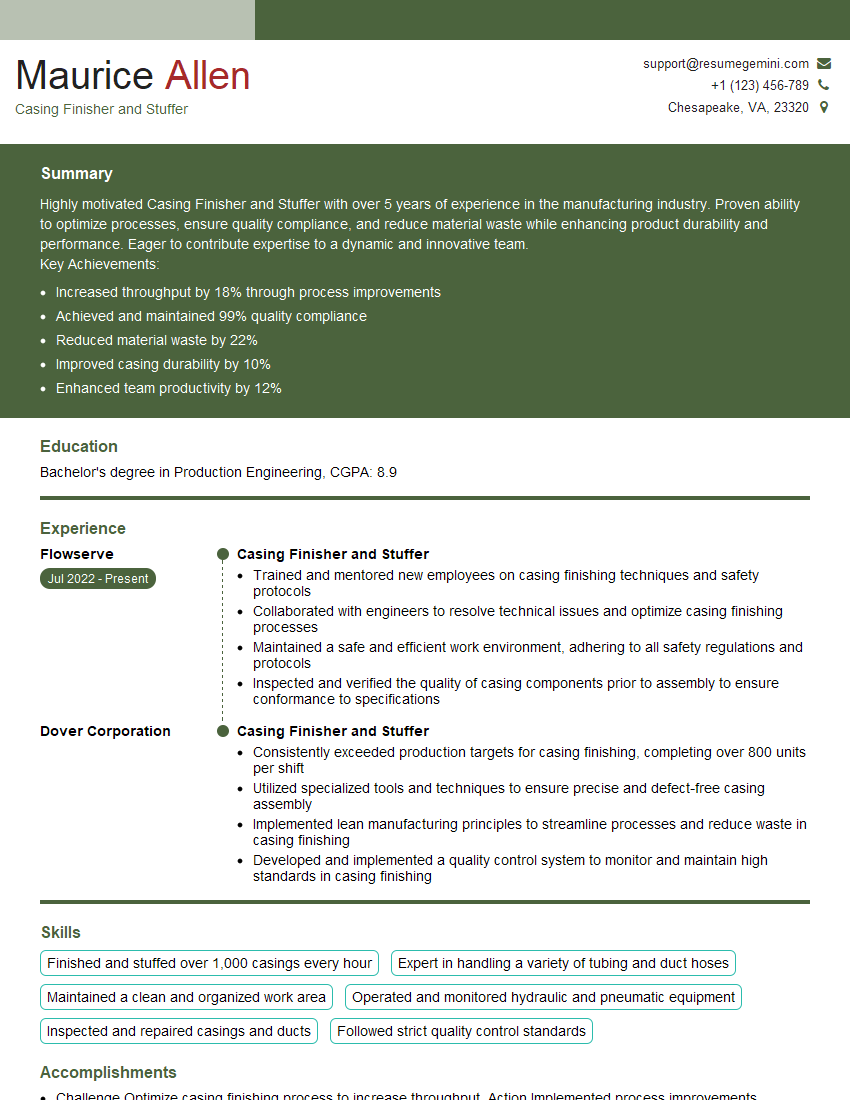

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Finisher and Stuffer

1. Explain the process of casing finishing, including the steps involved and the equipment used?

- Gather necessary materials, including casing, end caps, and adhesive.

- Cut the casing to the desired length using a miter saw.

- Apply adhesive to the inside of the casing and the end caps.

- Insert the end caps into the casing and secure them with clamps.

- Allow the adhesive to dry completely before removing the clamps.

- Use a sanding block to smooth any rough edges.

- Apply a finish, such as paint or stain, to protect the casing.

2. What are the different types of casing materials and their pros and cons?

Wood

- Pros: Natural beauty, durability, versatility

- Cons: Susceptible to moisture damage, can be expensive

Metal

- Pros: Durable, fire-resistant, easy to clean

- Cons: Can be expensive, can be difficult to work with

Plastic

- Pros: Lightweight, inexpensive, easy to install

- Cons: Not as durable as other materials, can be susceptible to fading

3. How do you ensure that the casing is properly aligned and secure?

- Use a level to ensure that the casing is level.

- Use a square to ensure that the casing is square.

- Secure the casing with screws or nails.

- Check the casing for any gaps or leaks.

- Caulk any gaps or leaks to prevent air or moisture from entering.

4. What are the safety precautions that should be taken when working with casing?

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from cuts and abrasions.

- Use a dust mask to protect your lungs from dust.

- Use a respirator when working with toxic materials.

- Be aware of your surroundings and be careful not to trip or fall.

5. What is the difference between a casing finisher and a stuffer?

- A casing finisher is responsible for the final finishing of the casing, including cutting, sanding, and applying a finish.

- A stuffer is responsible for stuffing the casing with meat or other food products.

6. What are the different types of stuffing machines?

- Manual stuffing machines

- Electric stuffing machines

- Hydraulic stuffing machines

7. How do you operate a stuffing machine?

- Load the meat or other food product into the hopper.

- Attach the casing to the stuffing horn.

- Start the stuffing machine and allow the meat or other food product to fill the casing.

- Once the casing is full, remove it from the stuffing horn and tie it off.

8. What is the difference between a natural casing and a synthetic casing?

- Natural casings are made from the intestines of animals.

- Synthetic casings are made from man-made materials, such as plastic or collagen.

9. What are the pros and cons of using natural casings?

Pros:

- Natural casings are more flexible and easier to work with than synthetic casings.

- Natural casings have a more natural flavor and texture.

Cons:

- Natural casings are more expensive than synthetic casings.

- Natural casings are more susceptible to spoilage.

10. What are the pros and cons of using synthetic casings?

Pros:

- Synthetic casings are less expensive than natural casings.

- Synthetic casings are more durable and less susceptible to spoilage.

Cons:

- Synthetic casings are more difficult to work with than natural casings.

- Synthetic casings have a less natural flavor and texture.

11. What are some of the common problems that can occur when using a stuffing machine?

- The casing can become clogged.

- The meat or other food product can become stuck in the hopper.

- The stuffing machine can overheat.

12. How do you troubleshoot common problems that can occur when using a stuffing machine?

- If the casing becomes clogged, clear the clog using a toothpick or other sharp object.

- If the meat or other food product becomes stuck in the hopper, remove the hopper and clear the obstruction.

- If the stuffing machine overheats, turn it off and allow it to cool down.

13. What are some of the safety precautions that should be taken when using a stuffing machine?

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from cuts and abrasions.

- Use a dust mask to protect your lungs from dust.

- Be aware of your surroundings and be careful not to trip or fall.

14. What are some of the qualities of a good casing finisher and stuffer?

- Attention to detail

- Dexterity

- Patience

- Physical strength

15. What are your career goals?

- I would like to become a master casing finisher and stuffer.

- I would like to learn more about the meat industry.

- I would like to start my own casing finishing and stuffing business.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Finisher and Stuffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Finisher and Stuffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing Finishers and Stuffers play a crucial role in the manufacturing processes of sausage casings and stuffing them into the casings. Their primary responsibilities include:

1. Casing Finishing

Inspect and sort sausage casings for any defects or imperfections

- Trim excess fat, sinew, and other unwanted materials from casings

- Calibrate and operate casing finishing machines to clean, stretch, and prepare casings for stuffing

2. Stuffing

Load casings into stuffing machines and adjust settings to ensure proper filling

- Monitor stuffing process to prevent overfilling or underfilling

- Pack and store stuffed casings according to specifications

3. Quality Control

Inspect finished products for quality, consistency, and adherence to standards

- Identify and remove defective products

- Maintain accurate records and documentation related to production

4. Equipment Maintenance

Clean and maintain casing finishing and stuffing equipment to ensure optimal performance

- Perform minor repairs and troubleshoot equipment malfunctions

- Follow safety protocols and maintain a clean and organized work area

Interview Tips

To ace an interview for the position of Casing Finisher and Stuffer, it’s important to prepare thoroughly and showcase your skills and experience. Here are some tips to help you succeed:

1. Research the Company and Role

Before the interview, take time to research the company’s history, values, and products. This will give you a better understanding of the company culture and the specific requirements of the role.

- Review the job description carefully and identify the key responsibilities and qualifications

- Familiarize yourself with the industry and the latest trends in casing finishing and stuffing

2. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience in casing finishing and stuffing. Provide specific examples of your accomplishments, using the STAR method:

- Situation: Describe a situation or task that you were faced with

- Task: Explain the specific task or responsibility that you were responsible for

- Action: Describe the actions that you took to complete the task

- Result: Explain the positive outcome or impact of your actions

3. Demonstrate Your Problem-Solving Abilities

Casing Finishers and Stuffers often encounter challenges during the production process. Be prepared to discuss how you would handle common problems, such as equipment malfunctions, quality control issues, or production delays.

- Provide examples of situations where you successfully solved problems and improved efficiency

- Explain your approach to troubleshooting and finding solutions

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the role and the company. This is also a chance for you to clarify any details about the position or the company culture.

- Ask about the company’s plans for growth and innovation

- Inquire about opportunities for professional development and training

- Request additional details about the team you would be working with

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Casing Finisher and Stuffer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Casing Finisher and Stuffer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.