Are you gearing up for an interview for a Link Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Link Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

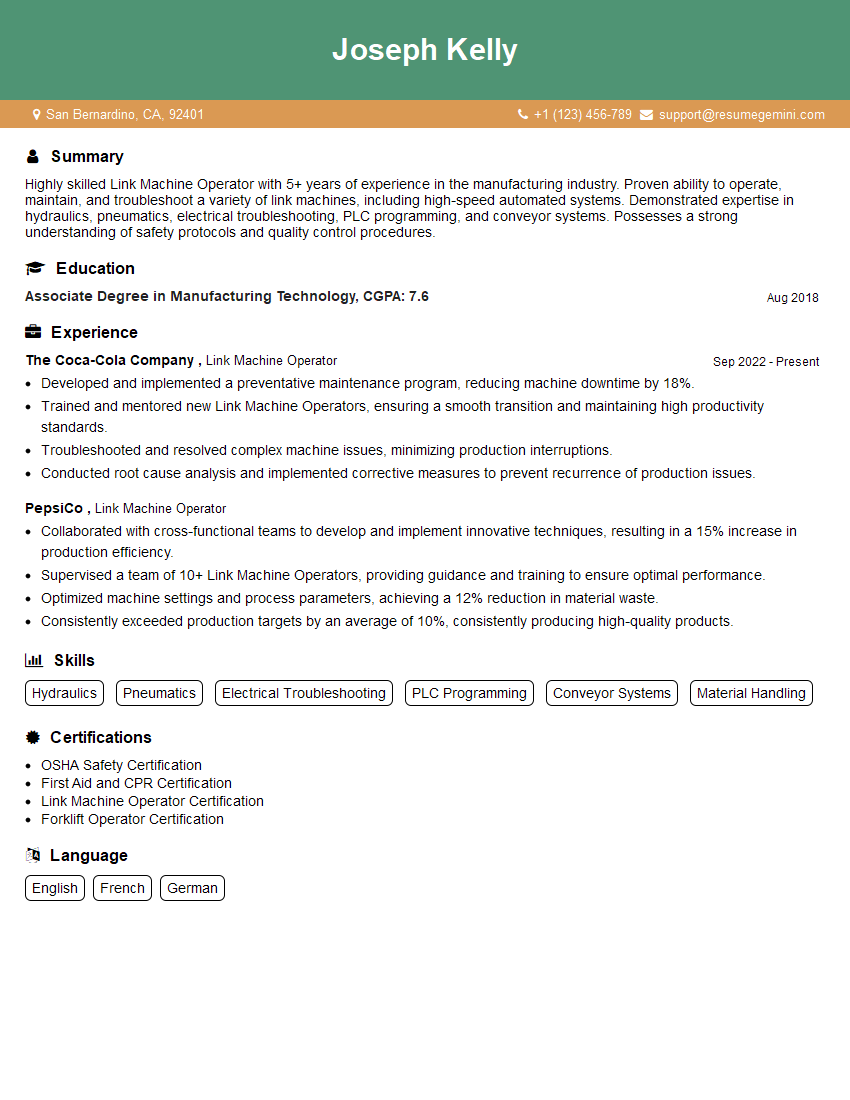

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Link Machine Operator

1. How would you determine the correct tension for the web on a link machine?

To determine the correct tension for the web on a link machine, I would follow these steps:

- Refer to the machine’s manual or manufacturer’s guidelines to determine the recommended tension range for the specific material and thickness being used.

- Start with the tension set at the lower end of the recommended range.

- Run the machine at a low speed and observe the web as it runs through the machine.

- Gradually increase the tension until the web is running smoothly without wrinkles, creases, or other defects.

- Once the optimal tension is achieved, make sure to monitor and adjust it as needed to maintain consistent web quality.

2. What are the key factors to consider when setting up a new link machine job?

Material:

The type of material being used, its thickness, and its properties.Machine specifications:

The capabilities and limitations of the specific link machine being used.Job requirements:

The desired output, including the number of links, the spacing between links, and the overall quality.Environmental factors:

The temperature, humidity, and other environmental conditions that may affect the process.Safety procedures:

Ensuring that all necessary safety precautions are in place.

3. How do you troubleshoot a link machine that is not feeding the web properly?

To troubleshoot a link machine that is not feeding the web properly, I would follow these steps:

- Check the tension of the web to ensure it is set correctly.

- Inspect the web guides and make sure they are clean and free of debris.

- Examine the feed rollers and ensure they are not worn or damaged.

- Check the drive system to make sure it is functioning properly.

- If the issue persists, consult the machine’s manual or contact the manufacturer for further troubleshooting assistance.

4. How do you maintain the accuracy of a link machine’s linking process?

Regular calibration:

Calibrating the link machine regularly according to the manufacturer’s instructions.Proper maintenance:

Keeping the machine clean, lubricated, and in good working condition.Quality control:

Regularly inspecting the output of the machine to ensure it meets the desired specifications.Use of precision tools:

Utilizing accurate measuring and alignment tools to set up the machine and monitor its performance.Training and experience:

Ensuring that operators are properly trained and have experience in operating the machine.

5. How do you handle a situation where the linked product does not meet the customer’s specifications?

Communication:

Promptly informing the customer of the issue and discussing the discrepancy in detail.Investigation:

Identifying the root cause of the problem, whether it’s a machine malfunction, material defect, or process error.Corrective action:

Taking immediate steps to resolve the issue and prevent it from recurring.Quality control:

Implementing additional quality control measures to ensure the product meets specifications going forward.Customer satisfaction:

Prioritizing customer satisfaction by providing clear updates, addressing their concerns, and offering solutions.

6. What are some of the most common challenges you face as a Link Machine Operator?

Material variations:

Dealing with different types and thicknesses of materials that require adjustments to machine settings.Machine breakdowns:

Troubleshooting and resolving mechanical issues to minimize downtime and maintain production efficiency.Quality control:

Maintaining high levels of precision and accuracy to meet customer specifications.Safety hazards:

Ensuring a safe work environment by following safety protocols and operating the machine properly.Time constraints:

Meeting production targets while adhering to quality standards.

7. How do you stay up-to-date on the latest advancements in linking technology?

Industry events:

Attending trade shows, conferences, and workshops to learn about new equipment and techniques.Training programs:

Participating in manufacturer-provided training programs to enhance skills and knowledge.Technical publications:

Reading industry magazines, articles, and whitepapers to stay informed about the latest developments.Online resources:

Utilizing online forums, discussion groups, and manufacturer websites to connect with other professionals and access information.Networking:

Building relationships with colleagues, suppliers, and industry experts to share knowledge and stay abreast of trends.

8. What are the different types of linking machines?

Mechanical linking machines:

Use mechanical components, such as gears and cams, to create the link.Ultrasonic linking machines:

Utilize ultrasonic vibrations to bond the material, creating a strong and consistent link.Thermal linking machines:

Use heat to melt or fuse the material together, forming a permanent link.Laser linking machines:

Employ lasers to cut and bond the material, resulting in precise and intricate links.Radio frequency (RF) linking machines:

Use radio frequency energy to heat and seal the material, creating a secure and durable link.

9. How do you determine the correct linking pattern for a particular product?

Product specifications:

Refer to the product’s design and technical requirements.Material properties:

Consider the thickness, strength, and flexibility of the material being used.Production efficiency:

Choose a pattern that optimizes productivity and minimizes waste.Machine capabilities:

Ensure the selected pattern is compatible with the machine’s capabilities.Quality standards:

Select a pattern that meets the required level of strength, durability, and aesthetic appeal.

10. What are some tips for optimizing the performance of a link machine?

Regular maintenance:

Keep the machine clean, lubricated, and calibrated to ensure smooth operation.Proper setup:

Carefully set up the machine according to the manufacturer’s instructions to ensure precision and accuracy.Use of high-quality materials:

Utilize materials that are compatible with the machine and meet the desired specifications.Monitoring and adjustment:

Regularly monitor the performance of the machine and make adjustments as needed to maintain optimal results.Training and experience:

Ensure operators are properly trained and experienced to operate the machine efficiently and effectively.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Link Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Link Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Link Machine Operators monitor, manage and operate machines that create links and connectors for various products. They work in production environments, following set procedures and ensuring high-quality standards.

1. Machine Operation

Operate and control link machines to produce links and connectors.

- Set up and adjust machines according to specifications.

- Monitor and control machine operations, ensuring optimal performance.

2. Quality Assurance

Inspect products for defects and ensure they meet quality standards.

- Conduct visual inspections to identify any abnormalities or defects.

- Use measuring instruments to ensure dimensional accuracy.

3. Production Monitoring

Monitor production processes to ensure efficiency and quality.

- Track production targets and make adjustments as needed.

- Identify and resolve any bottlenecks or issues affecting production.

4. Maintenance

Perform routine maintenance on machines to prevent breakdowns.

- Conduct regular cleaning and lubrication.

- Inspect and replace worn or damaged parts.

Interview Tips

Preparing for a Link Machine Operator interview requires understanding the role’s responsibilities and showcasing relevant skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s industry, products, and the specific requirements of the Link Machine Operator role. This demonstrates your interest and preparation.

- Visit the company website to learn about their products, services, and culture.

- Review the job description carefully and identify the key qualifications and responsibilities.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating link machines or similar equipment. Quantify your accomplishments whenever possible to demonstrate your impact.

- Describe your experience setting up, adjusting, and operating link machines.

- Provide specific examples of how you monitored production processes and ensured quality standards.

3. Demonstrate Problem-Solving Abilities

Link Machine Operators often encounter unexpected issues. Highlight your problem-solving skills by sharing examples of how you identified and resolved problems in previous roles.

- Discuss situations where you diagnosed and fixed machine malfunctions.

- Explain how you implemented solutions to improve production efficiency or quality.

4. Prepare for Technical Questions

Interviews for Link Machine Operator positions may include technical questions. Review the basics of link machine operation and be prepared to discuss topics such as:

- Types of links and connectors produced.

- Machine setup and adjustment procedures.

- Quality control techniques.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Link Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.