Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Preservative Filler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

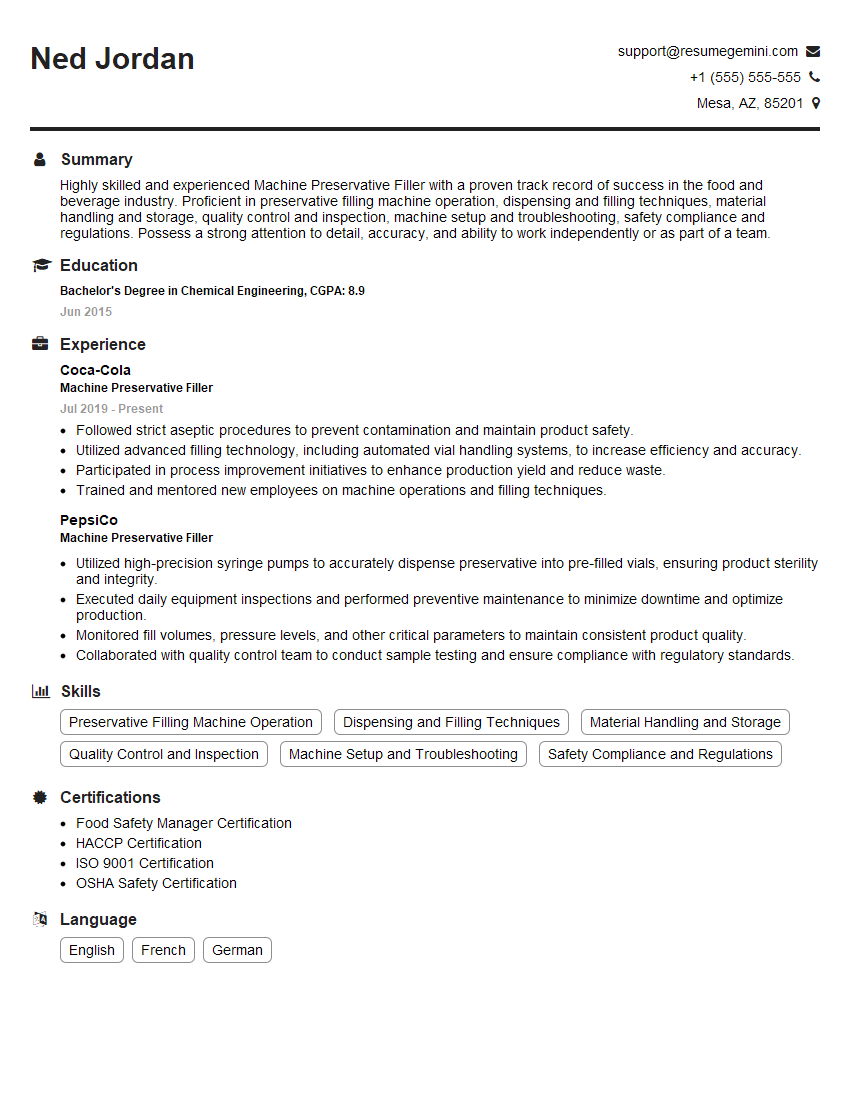

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Preservative Filler

1. Can you explain the process of preservative filling?

Preservative filling is a process of adding preservative to a product in order to extend its shelf life. The process involves several steps, including:

- Preparing the product for filling: This involves cleaning the product and removing any foreign objects.

- Filling the product with preservative: The preservative is typically injected into the product using a needle or syringe.

- Sealing the product: The product is then sealed to prevent the preservative from leaking out.

- Storing the product: The product is then stored in a cool, dry place to prevent the preservative from breaking down.

2. What are the different types of preservatives that can be used?

Chemical preservatives

- Sodium benzoate

- Potassium sorbate

- Calcium propionate

Natural preservatives

- Vinegar

- Lemon juice

- Salt

3. What are the factors that affect the effectiveness of a preservative?

The effectiveness of a preservative is affected by several factors, including:

- The type of preservative used

- The concentration of the preservative

- The pH of the product

- The temperature of the product

- The presence of other ingredients in the product

4. What are the safety concerns associated with the use of preservatives?

Some preservatives have been linked to health concerns, such as:

- Allergies

- Cancer

- Reproductive problems

It is important to use preservatives only when necessary and to follow the manufacturer’s instructions for use.

5. What are the alternatives to using preservatives?

There are several alternatives to using preservatives, including:

- Refrigeration

- Freezing

- Vacuum packaging

- Modified atmosphere packaging

6. What are the latest trends in preservative use?

The latest trends in preservative use include:

- The use of natural preservatives

- The development of new, more effective preservatives

- The use of preservative-free products

7. How do you ensure the quality of the preservative filling process?

The quality of the preservative filling process can be ensured by:

- Using high-quality ingredients

- Following the manufacturer’s instructions for use

- Regularly monitoring the filling process

- Testing the finished product to ensure that it meets specifications

8. What are the challenges of working as a Machine Preservative Filler?

The challenges of working as a Machine Preservative Filler include:

- Working in a fast-paced environment

- Working with hazardous materials

- Meeting production quotas

- Maintaining a clean and safe work area

9. What are the rewards of working as a Machine Preservative Filler?

The rewards of working as a Machine Preservative Filler include:

- Job security

- Competitive salary

- Opportunities for advancement

- The satisfaction of knowing that you are helping to preserve food and extend its shelf life

10. What are your career goals?

My career goals are to:

- Become a highly skilled Machine Preservative Filler

- Advance to a supervisory position

- Eventually become a manager in the food industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Preservative Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Preservative Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Preservative Fillers are pivotal members of the manufacturing team, responsible for ensuring the precision and efficiency of the preservative filling process. Their duties encompass a wide range of tasks, including:

1. Machine Operation

Skilled in operating various types of preservative filling machines, ensuring optimal performance and accuracy.

- Setting up and calibrating machines according to specifications.

- Monitoring machine performance, troubleshooting and resolving any issues promptly.

2. Material Handling

Properly handling and moving preservatives, ensuring their integrity and preventing contamination.

- Loading and unloading raw materials and finished products efficiently.

- Maintaining a clean and organized work area to prevent errors and accidents.

3. Quality Control

Diligent in adhering to quality standards, ensuring preservatives meet specifications.

- Inspecting preservatives visually and using appropriate testing methods.

- Reporting any deviations or defects to supervisors for corrective action.

4. Process Improvement

Continuously seeking ways to improve processes, enhance efficiency, and minimize waste.

- Identifying bottlenecks and suggesting solutions for optimization.

- Collaborating with team members to implement improvements and achieve production goals.

Interview Tips

To ace the interview for a Machine Preservative Filler position, candidates should:

1. Research the Company

Familiarize yourself with the company’s history, industry standing, and core values. This demonstrates your interest and enthusiasm for the role.

- Visit the company website, read press releases, and follow them on social media.

- Research the company’s competitors and the industry landscape to gain a comprehensive understanding.

2. Practice Your Answers

Craft thoughtful responses to common interview questions, showcasing your skills and experience. Practice delivering your answers confidently and concisely.

- Prepare examples of times you successfully operated or maintained machinery.

- Highlight instances where you implemented process improvements or resolved production issues.

3. Emphasize Safety

Stress your commitment to maintaining a safe work environment and adhering to all safety protocols.

- Explain your experience with safety equipment and emergency procedures.

- Discuss your understanding of the potential hazards associated with the job.

4. Demonstrate Attention to Detail

Convey your meticulous approach to work, highlighting your ability to notice and address even the smallest deviations.

- Provide examples of your attention to detail in previous roles or personal experiences.

- Emphasize your ability to follow instructions precisely and work independently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Preservative Filler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!