Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Milk Bottling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

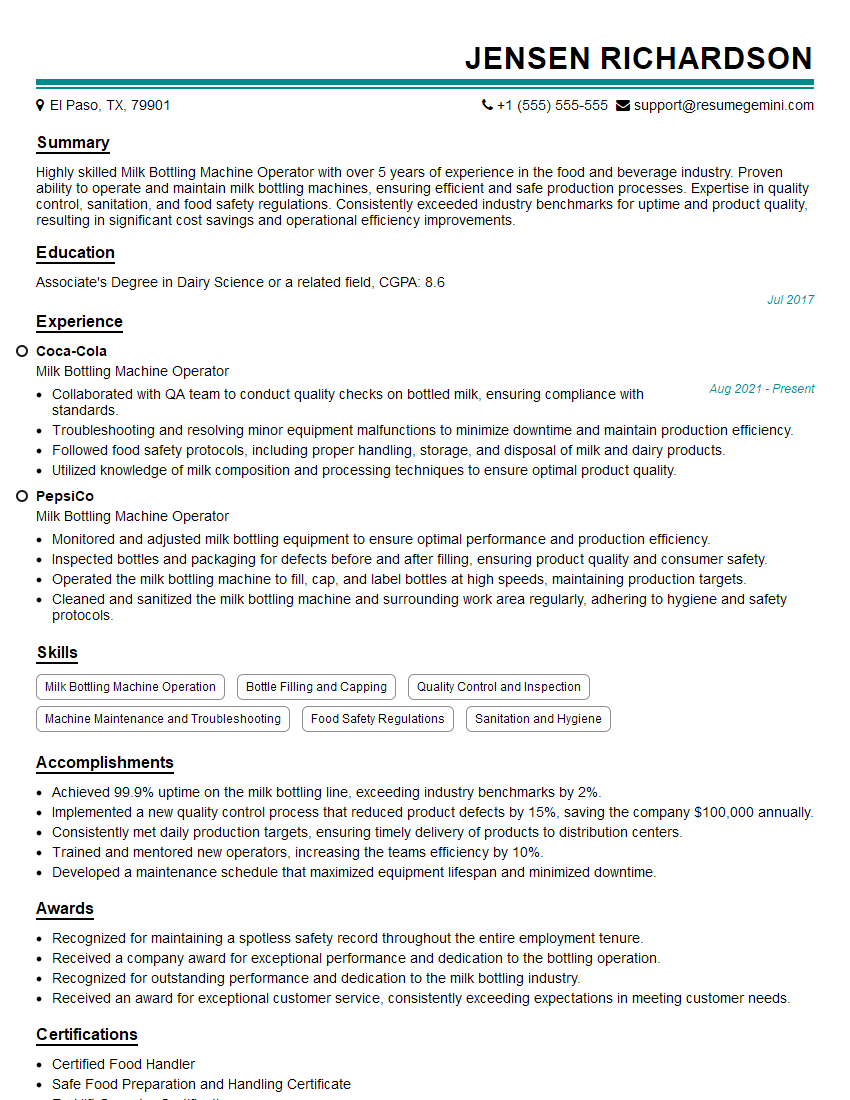

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milk Bottling Machine Operator

1. Can you tell me about your experience in operating milk bottling machines?

I have been working as a Milk Bottling Machine Operator for the past 5 years. In this role, I am responsible for operating and maintaining a variety of milk bottling machines, including bottle fillers, cappers, and labelers. I am also responsible for ensuring that the milk is bottled in a safe and sanitary manner.

2. What are the key functions of a Milk Bottling Machine Operator?

Machine Operation

- Operate and monitor milk bottling machines to fill, cap, and label bottles.

- Adjust machine settings to ensure proper bottle filling and sealing.

- Troubleshoot and resolve machine malfunctions.

Production Monitoring

- Monitor production rates and adjust machine settings to optimize efficiency.

- Inspect bottles for defects and remove any damaged or contaminated bottles.

- Maintain a clean and organized work area.

Safety and Sanitation

- Follow all safety protocols and procedures.

- Maintain a sanitary work environment by cleaning and disinfecting machinery and equipment.

- Wear appropriate personal protective equipment (PPE).

3. What are the most important safety precautions that you should take when operating a milk bottling machine?

- Never operate a machine without proper training and authorization.

- Always wear appropriate PPE, including gloves, safety glasses, and a hairnet.

- Keep your hands and clothing away from moving parts.

- Do not attempt to repair or adjust a machine while it is running.

- Report any spills or leaks immediately.

4. What are the most common problems that you have encountered when operating a milk bottling machine?

- Machine jams

- Bottle leaks

- Labeling errors

- Electrical malfunctions

- Sanitation issues

5. How do you troubleshoot a milk bottling machine?

- Identify the problem.

- Check for any obvious causes, such as a loose wire or a missing part.

- Refer to the machine’s manual for troubleshooting tips.

- If you cannot resolve the problem, contact a qualified technician.

6. What is the importance of maintaining a clean and sanitary work area when operating a milk bottling machine?

- To prevent contamination of the milk.

- To comply with food safety regulations.

- To create a safe and healthy work environment.

7. What are the different types of milk bottling machines that you have experience with?

- Rotary fillers

- Inline fillers

- Gravity fillers

- Cappers

- Labelers

8. What are the advantages and disadvantages of using a rotary filler?

Advantages

- High speed and efficiency

- Accurate filling

- Easy to operate and maintain

Disadvantages

- More expensive than other types of fillers

- Requires more space

- Can be more difficult to clean

9. What are the safety features that you should look for when purchasing a milk bottling machine?

- Emergency stop buttons

- Guarding around moving parts

- Interlocks to prevent machine operation when guards are open

- Non-slip surfaces

- Proper lighting

10. What are your career goals?

My career goal is to become a Production Supervisor in the dairy industry. I am confident that I have the skills and experience necessary to succeed in this role. I am a hard worker, I am always willing to learn new things, and I am passionate about the dairy industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milk Bottling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milk Bottling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Milk Bottling Machine Operator is responsible for ensuring the smooth and efficient operation of milk bottling machines in a dairy or manufacturing setting. Key job responsibilities include:

1. Machine Operation and Maintenance

Monitoring and operating milk bottling machines to ensure proper filling, capping, and labelling of milk containers.

- Adjusting machine settings to optimize performance and minimize waste.

- Conducting regular maintenance and cleaning of machines to ensure safety and hygiene.

2. Quality Control

Inspecting milk bottles for defects, leaks, or contamination before packaging.

- Monitoring product flow to ensure proper packaging and labelling, adhering to quality standards.

- Taking corrective actions to address any quality issues promptly.

3. Production Management

Monitoring production schedules and ensuring timely completion of bottling operations.

- Coordinating with other departments to ensure a consistent supply of materials and equipment.

- Maintaining an organized and clean work area, adhering to safety regulations.

4. Troubleshooting

Identifying and resolving operational issues with milk bottling machines.

- Performing minor repairs and adjustments to keep machines running smoothly.

- Reporting major equipment malfunctions to supervisors for timely resolution.

Interview Tips

Preparing for an interview for a Milk Bottling Machine Operator position requires careful preparation and knowledge of the industry.

1. Research the Company and Position

Research the dairy or manufacturing company you are applying to, and the specific responsibilities of the Milk Bottling Machine Operator role. This will help you understand the company’s needs and tailor your answers accordingly.

- Familiarize yourself with the company’s mission, values, and products.

- Review the job description thoroughly to identify key skills and requirements.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating and maintaining milk bottling machines, as well as your knowledge of quality control procedures. Highlight any skills that are relevant to the position, such as mechanical aptitude, problem-solving abilities, and attention to detail.

- Quantify your accomplishments whenever possible using specific examples.

- Explain how your skills and experience align with the job requirements.

3. Demonstrate Strong Work Ethic and Safety Awareness

Milk bottling operations require a strong work ethic, attention to detail, and a commitment to safety. Highlight your willingness to work in a fast-paced environment and your ability to follow safety protocols strictly.

- Provide examples of your ability to work independently and as part of a team.

- Explain your understanding of safety regulations and your experience in maintaining a clean and organized work area.

4. Prepare Questions for the Interviewer

Preparing questions for the interviewer shows that you are engaged and interested in the position. Ask thoughtful questions about the company, the role, and the industry. This also gives you an opportunity to clarify any information or address any concerns you may have.

- Ask about the company’s growth plans and the potential for advancement within the role.

- Inquire about the company’s commitment to quality and safety standards.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Milk Bottling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.