Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sealer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

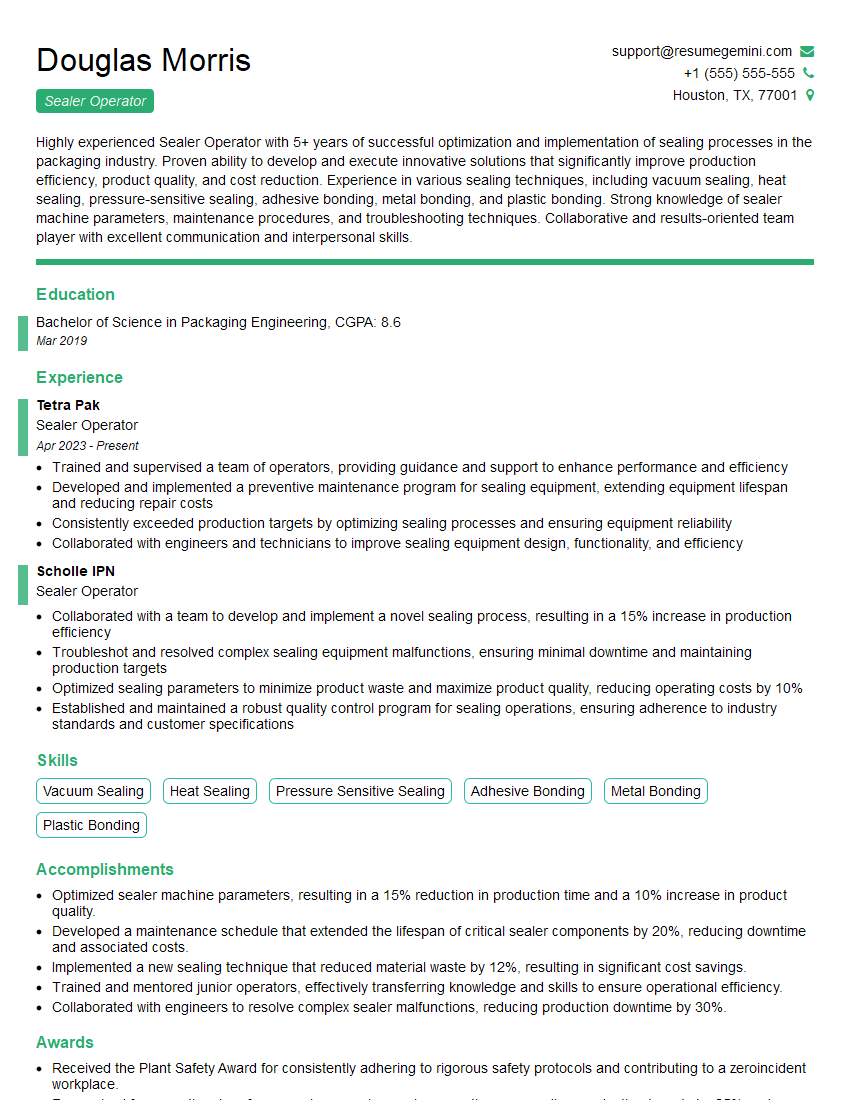

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sealer Operator

1. What are the key responsibilities of a Sealer Operator?

As a Sealer Operator, my main responsibilities include:

- Operating and maintaining sealing equipment to ensure proper sealing of products and packages

- Monitoring and adjusting sealing parameters to optimize sealing quality and efficiency

- Performing routine maintenance and repairs on sealing equipment to prevent breakdowns and ensure optimal performance

- Inspecting and verifying the quality of sealed products to meet customer specifications

- Adhering to safety protocols and regulations to ensure a safe work environment

2. What types of sealing equipment have you operated and maintained?

Vacuum Sealers:

- Chamber vacuum sealers

- External vacuum sealers

Heat Sealers:

- Impulse heat sealers

- Continuous heat sealers

- Band sealers

Other Types:

- Lidding machines

- Shrink wrappers

- Conveyors and feeding systems

3. What are the common problems you encounter with sealing equipment and how do you resolve them?

Some common problems I encounter include:

- Leaking seals: Caused by worn or damaged sealing elements. Resolved by replacing or repairing the seals.

- Poor seal quality: Caused by incorrect sealing parameters or faulty equipment. Resolved by adjusting parameters or repairing the equipment.

- Equipment breakdowns: Caused by mechanical or electrical failures. Resolved by performing repairs or replacing components.

- Contamination: Caused by improper handling or equipment malfunctions. Resolved by cleaning and sanitizing the equipment.

- Safety hazards: Caused by improper operation or maintenance. Resolved by following safety protocols and performing regular inspections.

4. How do you ensure the quality of sealed products?

I ensure the quality of sealed products by:

- Inspecting incoming materials and packaging

- Monitoring sealing parameters during the process

- Performing random product inspections

- Following established quality control procedures

- Maintaining proper documentation and records

5. What are the safety precautions you follow when operating sealing equipment?

I follow these safety precautions:

- Wearing appropriate personal protective equipment (PPE)

- Ensuring the equipment is properly grounded and maintained

- Following lockout/tagout procedures before performing any repairs or maintenance

- Never leaving the equipment unattended while in operation

- Reporting any safety hazards or concerns immediately

6. What is your experience with implementing and maintaining sanitation and hygiene standards in a sealing operation?

I have experience in:

- Developing and implementing sanitation and hygiene procedures

- Training staff on proper sanitation practices

- Cleaning and sanitizing equipment and work areas on a regular basis

- Monitoring and recording sanitation activities

- Adhering to food safety regulations and industry best practices

7. How do you handle high-volume production demands while maintaining product quality and efficiency?

To handle high-volume production demands while maintaining product quality and efficiency, I:

- Optimize sealing parameters to maximize throughput

- Maintain a regular maintenance schedule to prevent breakdowns

- Implement automation and lean manufacturing techniques

- Train and empower staff to increase productivity

- Monitor production processes and make adjustments as needed

8. What is your understanding of Good Manufacturing Practices (GMPs)?

GMPs are a set of regulations designed to ensure the safety and quality of food products. I understand that GMPs include:

- Proper sanitation and hygiene practices

- Control of production processes

- Quality assurance and control measures

- Documentation and record-keeping

- Training and supervision of staff

9. How do you stay updated on the latest advancements in sealing technology?

I stay updated by:

- Attending industry conferences and exhibitions

- Reading trade publications and technical journals

- Participating in online forums and webinars

- Consulting with equipment manufacturers and suppliers

- Seeking opportunities for professional development and training

10. Why are you interested in this Sealer Operator position?

I am interested in this position because I am passionate about ensuring product quality and safety in the food and packaging industry. I am confident that my technical skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sealer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sealer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sealer Operators are crucial to the packaging and shipping processes. They operate and maintain sealing equipment, ensuring that products are securely packaged for transportation. Key job responsibilities include:

1. Operate sealing equipment

Operate and monitor sealing equipment, such as heat sealers, shrink wrappers, and vacuum sealers.

- Adjust machine settings to ensure proper sealing.

- Monitor equipment performance and troubleshoot any issues.

2. Inspect products and packaging

Inspect products and packaging before and after sealing to ensure quality and accuracy.

- Check for damage, contamination, or defects.

- Verify that products are correctly labeled and packaged.

3. Maintain work area and equipment

Maintain a clean and organized work area and ensure that equipment is in good working order.

- Clean and disinfect work surfaces and equipment regularly.

- Perform routine maintenance and repairs as needed.

4. Follow safety procedures

Follow established safety procedures and wear appropriate protective gear to ensure a safe work environment.

- Adhere to workplace safety regulations and guidelines.

- Report any safety hazards or concerns promptly.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Sealer Operator interview:

1. Research the company and position

Familiarize yourself with the company’s history, products, and culture. Research the specific role you’re applying for and its responsibilities.

- Visit the company’s website and social media pages.

- Read industry news and articles related to sealing operations.

2. Practice common interview questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples from your experience that demonstrate your skills and abilities.

3. Highlight your relevant skills and experience

Emphasize your experience in operating and maintaining sealing equipment. Quantify your accomplishments and provide concrete examples of how you have contributed to the efficiency and accuracy of packaging processes.

- Describe any training or certifications you have obtained in sealing operations.

- Share your knowledge of different types of packaging materials and their properties.

4. Be enthusiastic and professional

Convey your enthusiasm for the role and the opportunity to contribute to the company. Dress professionally and maintain a positive attitude throughout the interview.

- Ask thoughtful questions to demonstrate your interest and engagement.

- Thank the interviewers for their time and consideration.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sealer Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sealer Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.