Are you gearing up for a career in Strapping Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Strapping Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

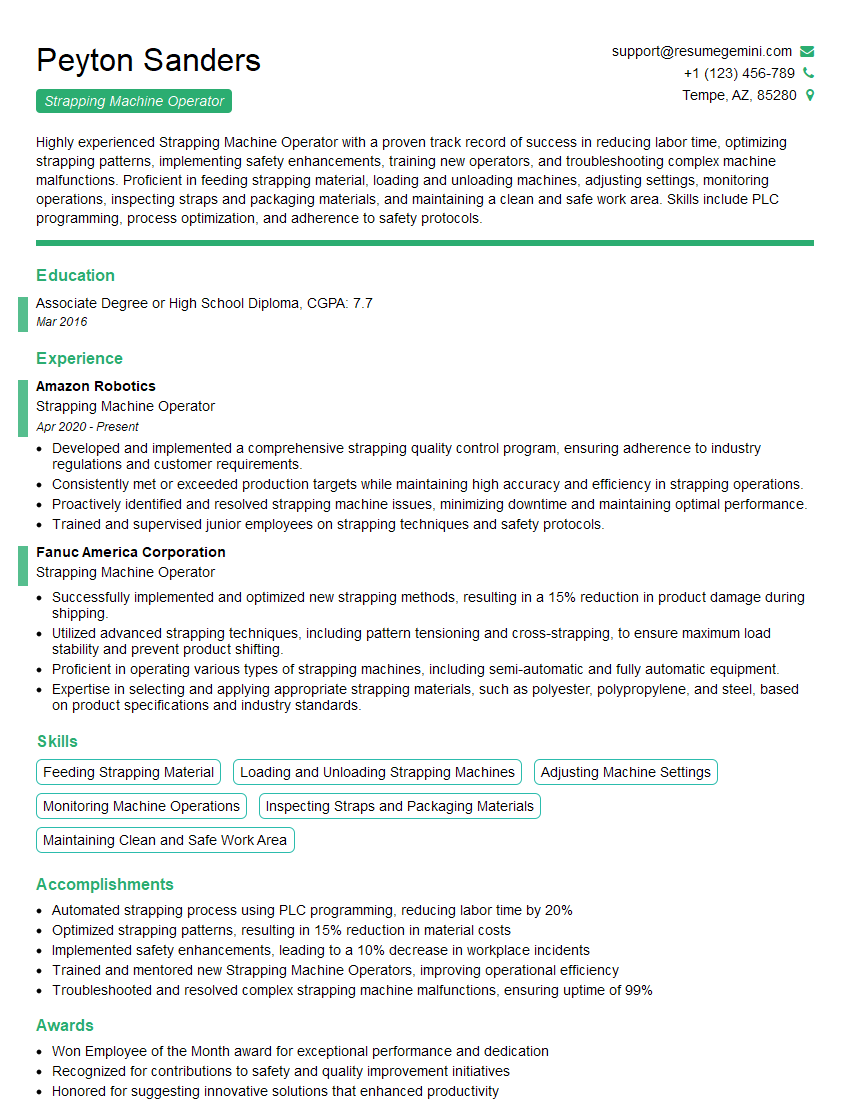

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strapping Machine Operator

1. Describe the types of strapping machines you have operated and explain their key differences?

In my previous role, I have operated both semi-automatic and fully automatic strapping machines. Semi-automatic machines require the operator to manually feed the straps, while fully automatic machines can automatically dispense, tension, and seal the straps. They also vary in terms of the type of straps they can handle, such as plastic, steel, or textile.

2. Explain the process of tensioning and sealing straps using a strapping machine?

Tensioning

- Set the tensioning force according to the weight and material of the package.

- Feed the strap through the tensioning mechanism, which creates friction pulling on the strap.

Sealing

- Choose the appropriate sealing method, such as heat sealing or friction welding.

- Apply the sealing mechanism to the overlapping ends of the strap, creating a strong and secure bond.

3. Describe the safety precautions that must be taken when operating a strapping machine?

To ensure safe operation of a strapping machine, it is essential to:

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures before performing any maintenance or repairs.

- Keep the work area clean and clear of debris to prevent tripping hazards.

- Never operate the machine with damaged or loose components.

4. Explain how to troubleshoot common problems that occur with strapping machines?

Some common problems with strapping machines include:

- Straps not feeding properly – Check if the strap path is clear, tension is set correctly, and the dispenser is functioning.

- Straps not tensioning – Adjust the tensioning force or check for worn tensioning components.

- Straps not sealing – Verify the sealing temperature or force is adequate, and clean the sealing mechanism.

5. Describe your experience in maintaining and repairing strapping machines?

I have performed regular maintenance tasks on strapping machines, including:

- Lubricating moving parts

- Cleaning and inspecting components

- Replacing worn or damaged parts

For more complex repairs, I have worked with qualified technicians to diagnose and resolve issues.

6. Explain how you ensure the quality of strapped packages?

To ensure the quality of strapped packages, I follow these steps:

- Inspect the packaging materials and straps for any damage or defects.

- Set the appropriate tension and sealing parameters for the package weight and material.

- Visually check the strapped package to ensure the straps are evenly tensioned and securely sealed.

- Perform random quality checks throughout the day to monitor the consistency of the strapping process.

7. Describe your experience in working in a fast-paced production environment?

I have worked in a fast-paced production environment for the past 5 years, where I was responsible for operating a high-volume strapping machine. I was able to maintain a consistent output while meeting strict quality standards. I am comfortable working under pressure and can prioritize tasks effectively.

8. Explain how you stay up-to-date on the latest strapping techniques and technologies?

To stay up-to-date with the latest strapping techniques and technologies, I:

- Attend industry seminars and workshops.

- Read trade publications and articles.

- Network with other strapping professionals.

- Participate in online forums and discussions.

9. What motivated you to apply for this Strapping Machine Operator position?

I am eager to join your company as a Strapping Machine Operator because I am confident that my skills and experience would make me a valuable asset to your team. I am proficient in operating both semi-automatic and fully automatic strapping machines and have a strong understanding of the principles of tensioning and sealing. I am also committed to maintaining a high level of quality and efficiency in my work.

10. What are your salary expectations for this position?

My salary expectations are in line with the industry average for a Strapping Machine Operator with my experience and qualifications. I am open to discussing the salary range and benefits package that you have available.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strapping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strapping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Strapping Machine Operators are responsible for the operation and maintenance of strapping machines, which are used to secure and bundle products for shipping and storage. The primary objective of this role is to ensure that products are packaged securely and efficiently, minimizing the risk of damage or loss during transit or storage.

1. Machine Operation:

• Operating and monitoring strapping machines to secure products with straps or bands

• Adjusting machine settings to accommodate different product sizes and shapes

• Ensuring that machines operate smoothly and efficiently

2. Product Handling:

• Loading and unloading products onto and from the strapping machine

• Inspecting products for damage or defects before strapping

• Positioning products correctly on the machine for optimal strapping

3. Strap and Material Management:

• Selecting and loading the appropriate type and size of strapping materials

• Monitoring strap tension to ensure secure packaging

• Maintaining a clean and organized work area

4. Quality Control:

• Inspecting strapped products to ensure proper packaging

• Identifying and correcting packaging errors

• Ensuring that straps are applied according to company standards and specifications

Interview Tips

Interview preparation is crucial for a successful outcome. Here are some tips and hacks to help you ace your Strapping Machine Operator interview:

1. Research the Company and Role:

• Visit the company’s website to learn about its history, products, and culture.

• Study the job description thoroughly to understand the specific responsibilities and requirements.

2. Highlight Relevant Skills and Experience:

• Emphasize any previous experience operating strapping machines or similar equipment.

• Showcase your attention to detail, precision, and ability to follow instructions.

• Mention your understanding of product handling and packaging principles.

3. Practice Common Interview Questions:

• Prepare for questions about your experience, skills, and motivation for applying for this role.

• Consider using the STAR method to answer behavioral questions, providing specific examples to demonstrate your capabilities.

• Practice answering questions about your strengths and weaknesses.

4. Dress Professionally and Arrive on Time:

• First impressions matter, so dress professionally and arrive for your interview on time.

• This shows respect for the interviewer’s time and demonstrates your professionalism.

• Be polite and respectful throughout the interview process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Strapping Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.