Are you gearing up for a career in Gettering Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gettering Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

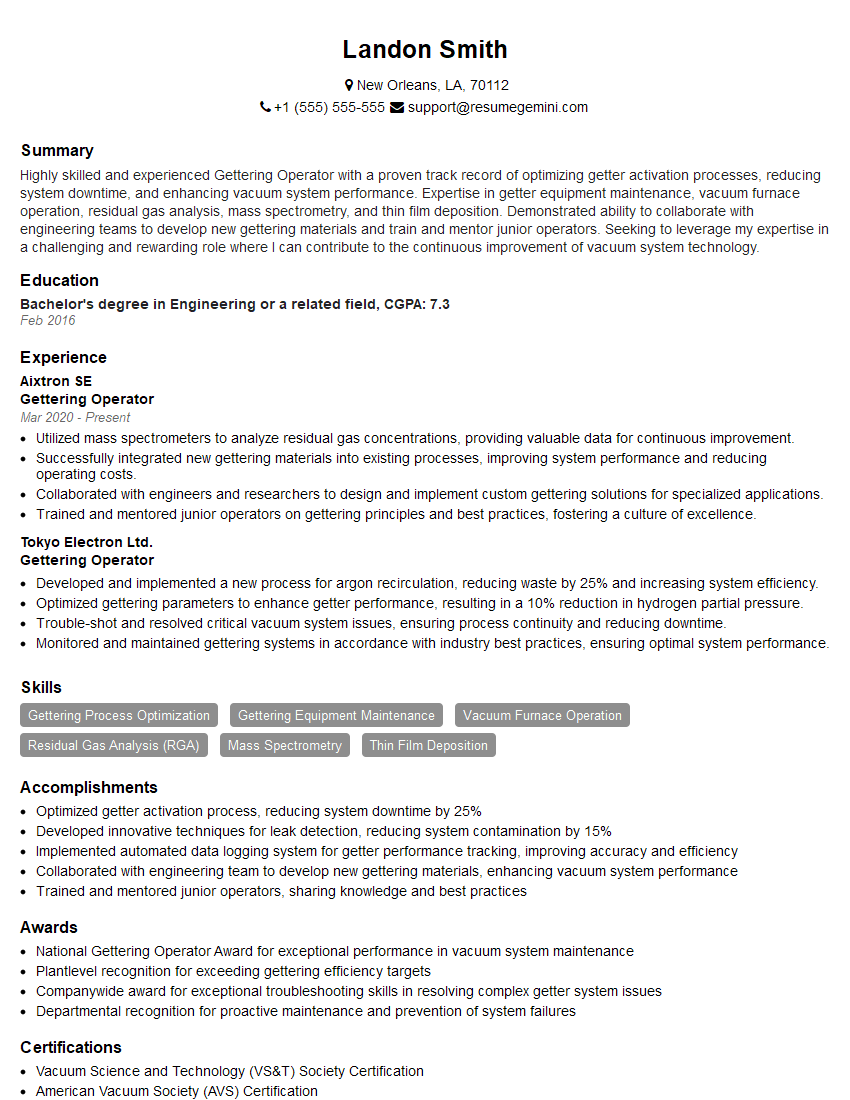

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gettering Operator

1. What are the primary responsibilities of a Gettering Operator?

- Operate getter machines to remove unwanted gases from vacuum tubes and other electronic devices.

- Monitor and maintain equipment, ensuring optimal performance and safety.

2. Describe the different types of getters used in gettering processes.

Sublimation getters:

- Evaporate at low temperatures, releasing gases that react with impurities.

- Common materials: barium, aluminum, magnesium.

Dispenser getters:

- Contain active material within a porous structure.

- Release gases when heated, providing continuous gettering action.

- Common materials: barium oxide, titanium.

3. Explain the process of degassing a vacuum tube using a gettering machine.

- Load the tube into the gettering chamber.

- Initiate the gettering process, causing the getter to release gases.

- The gases react with and remove impurities from the tube.

- Monitor the pressure and temperature during the process to ensure proper degassing.

4. What safety protocols must be followed when working with getters?

- Wear appropriate protective gear (gloves, mask, etc.).

- Handle getters carefully to avoid contamination.

- Work in a well-ventilated area.

- Dispose of getters according to established procedures.

5. How do you troubleshoot common issues encountered in gettering operations?

Getter activation failure:

- Check heating elements and electrical connections.

- Inspect getter geometry and ensure proper placement.

Insufficient gettering:

- Verify that the proper getter type is used.

- Check the gettering time and temperature.

- Inspect getter surface for any contamination.

6. Describe the maintenance procedures required for gettering machines.

- Regularly clean the chamber and components.

- Inspect heating elements, electrical contacts, and vacuum seals.

- Calibrate vacuum gauges and other monitoring devices.

- Perform preventive maintenance as per manufacturer’s recommendations.

7. How do you ensure the quality of gettered products?

- Use standardized process parameters and quality control procedures.

- Inspect the appearance and performance of gettered devices.

- Conduct residual gas analysis to verify gas removal efficiency.

- Maintain documentation to track production and quality data.

8. What are the emerging trends in gettering technology?

- Development of advanced getter materials with higher efficiency and longevity.

- Integration of gettering into semiconductor fabrication processes.

- Use of getters for air purification and gas sensing applications.

9. Describe a challenging gettering project you have worked on and how you overcame the challenges.

Example Answer: I worked on a project to improve the gettering efficiency of a vacuum tube used in a high-power microwave amplifier. The original getter was not effective at removing certain trace gases. I conducted extensive research and experimented with different getter materials and activation methods. I developed a novel getter alloy that significantly improved gettering performance, resulting in a substantial reduction in residual gas pressure and enhanced device reliability.

10. What are your strengths and weaknesses as a Gettering Operator?

Example Answer:Strengths: In-depth knowledge of gettering technologies, proven ability to troubleshoot and maintain gettering equipment, strong attention to detail, excellent communication and teamwork skills. Weaknesses: Limited experience with some advanced gettering techniques, eagerness to take on too many responsibilities at once.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gettering Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gettering Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gettering Operators are vital members of the semiconductor manufacturing team, ensuring the high quality and reliability of electronic devices through their specialized role.

1. Wafer Preparation and Processing

Meticulously prepare silicon wafers for gettering processes by cleaning, etching, and coating them to meet precise specifications.

- Clean wafers to remove contaminants that could interfere with gettering.

- Etch the wafer’s surface to create microscopic defects that act as gettering sites.

- Apply a thin coating of a gettering material, such as phosphorus or arsenic, to attract and bind impurities.

2. Gettering Equipment Operation

Skillfully operate and maintain gettering equipment, ensuring optimal process conditions and maximizing efficiency.

- Monitor and adjust temperature, pressure, and gas flow parameters to achieve desired gettering results.

- Troubleshoot equipment malfunctions and perform routine maintenance to ensure seamless operation.

- Follow established procedures and safety protocols to prevent contamination and accidents.

3. Quality Control and Inspection

Diligently inspect wafers after gettering to verify their quality and adherence to specifications.

- Use microscopes and other inspection tools to examine wafers for defects, contamination, and other anomalies.

- Document inspection results and report any deviations to ensure traceability and maintain quality standards.

- Collaborate with engineers and technicians to improve gettering processes and optimize product quality.

4. Process Optimization and Yield Improvement

Actively participate in continuous improvement efforts to enhance gettering processes and increase wafer yield.

- Analyze process data and identify areas for improvement to reduce defects and enhance device performance.

- Suggest and implement process modifications to increase gettering efficiency and minimize contamination.

- Contribute to research and development projects to advance gettering technologies.

Interview Tips

Preparing for a Gettering Operator interview requires a comprehensive approach to showcase your skills and knowledge. Here’s a guide to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the company you’re applying to and the semiconductor industry. Understand their products, services, and market position.

- Visit the company’s website and read industry publications to gather relevant information.

- Identify recent developments and trends in semiconductor manufacturing, especially in gettering technologies.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills related to wafer preparation, gettering equipment operation, and quality control.

- Quantify your accomplishments and use specific examples to demonstrate your proficiency.

- Mention any relevant certifications or training programs you have completed.

3. Demonstrate Problem-Solving Abilities

Showcase your ability to analyse problems, troubleshoot equipment, and develop solutions.

- Describe a challenging situation you faced in a previous role and how you successfully resolved it.

- Explain how you would approach a hypothetical problem related to gettering.

4. Prepare for Technical Questions

Anticipate technical questions about gettering processes, equipment, and quality control procedures.

- Review the basics of gettering, including the principles, materials, and equipment used.

- Practice answering questions about wafer preparation, equipment operation, and inspection techniques.

5. Ask Thoughtful Questions

Asking intelligent questions shows your engagement and interest in the role.

- Inquire about the company’s specific gettering processes and the challenges they face.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gettering Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!