Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hot Dipper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hot Dipper so you can tailor your answers to impress potential employers.

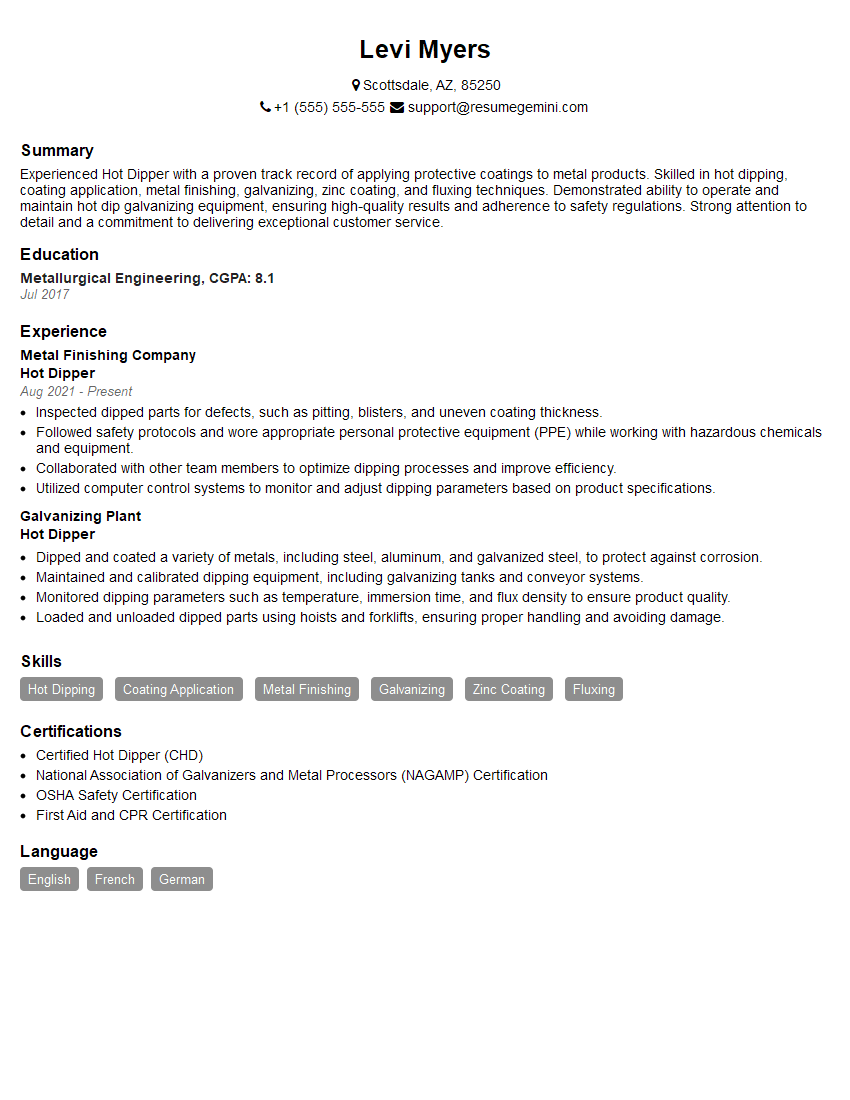

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Dipper

1. Describe the steps involved in the hot dipping process for galvanizing steel?

- Prepare the steel by cleaning and pickling it to remove any rust or impurities.

- Flux the steel to remove any oxides and create a protective layer.

- Dip the steel into a molten zinc bath at a temperature of around 450°C (842°F).

- Hold the steel in the zinc bath for a period of time to allow the zinc to coat the surface.

- Remove the steel from the zinc bath and allow it to cool.

2. What are the different types of hot dip galvanizing processes?

Batch Hot-Dip Galvanizing

- Steel products are submerged in a kettle of molten zinc.

- Used for large, heavy steel structures, such as bridges and buildings.

Continuous Hot-Dip Galvanizing

- Steel strip or wire is passed through a molten zinc bath.

- Used for mass production of galvanized steel products, such as roofing and siding.

Sendzimir Galvanizing

- Combination of batch and continuous processes.

- Steel strip is passed through a molten zinc bath, then through a series of rollers to control the thickness of the zinc coating.

3. What are the advantages and disadvantages of hot dip galvanizing?

- Provides excellent corrosion protection.

- Durable and long-lasting.

- Relatively low cost.

- Can be used on a variety of steel products.

- Can create a rough surface finish.

- May not be suitable for all applications.

- Can release toxic fumes during the process.

Advantages:

Disadvantages:

4. What are the quality control measures that should be followed during hot dip galvanizing?

- Inspect the steel before galvanizing to ensure it is free of rust and impurities.

- Control the temperature of the zinc bath to ensure it is within the proper range.

- Monitor the thickness of the zinc coating to ensure it meets the required specifications.

- Perform adhesion tests to ensure the zinc coating is properly bonded to the steel.

- Inspect the finished product for any defects.

5. What are the safety precautions that should be taken when working with hot dip galvanizing?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Be aware of the potential for burns and other injuries when working with molten zinc.

- Handle and store zinc safely to prevent spills and leaks.

- Follow proper ventilation procedures to prevent the buildup of toxic fumes.

- Be trained on the proper operation of hot dip galvanizing equipment.

6. What are the environmental regulations that apply to hot dip galvanizing?

- The environmental regulations that apply to hot dip galvanizing vary depending on the country or region.

- In general, these regulations focus on controlling the release of toxic fumes and wastewater.

- Hot dip galvanizers must comply with these regulations by using proper pollution control equipment and following best management practices.

7. What are the emerging trends in hot dip galvanizing?

- The use of zinc-aluminum alloys to improve corrosion resistance and extend the life of galvanized products.

- The development of new processes to reduce the environmental impact of hot dip galvanizing.

- The use of automation and technology to improve the efficiency and quality of hot dip galvanizing operations.

8. What are the different types of fluxes used in hot dip galvanizing?

- Acid fluxes

- Neutral fluxes

- Organic fluxes

- Inorganic fluxes

Acid fluxes:

- Most commonly used.

- Contain hydrochloric acid or zinc chloride.

- Remove oxides and create a clean surface for galvanizing.

Neutral fluxes:

- Do not contain any acid.

- Create a protective layer on the steel surface.

- Used for galvanizing steel with a high carbon content.

Organic fluxes:

- Contain organic compounds, such as rosin or vegetable oils.

- Create a protective layer on the steel surface.

- Used for galvanizing steel with a low carbon content.

Inorganic fluxes:

- Contain inorganic compounds, such as ammonium chloride or zinc chloride.

- Create a protective layer on the steel surface.

- Used for galvanizing steel with a high carbon content.

9. What are the factors that affect the thickness of the zinc coating in hot dip galvanizing?

- Temperature of the zinc bath

- Immersion time

- Steel composition

- Surface preparation

- Flux type

- Withdrawal speed

10. What are the different types of post-treatment options for hot dip galvanized steel?

- Chromating

- Painting

- Powder coating

Chromating:

- Chemical conversion process that creates a thin, protective layer on the galvanized surface.

- Improves corrosion resistance and provides a better surface for painting or powder coating.

Painting:

- Applied to the galvanized surface to provide additional protection against corrosion.

- Can be used to match the color of the surrounding environment.

Powder coating:

- Applied to the galvanized surface as a dry powder.

- Heated to create a tough, durable finish.

- Provides excellent corrosion resistance and can be used to create a variety of colors and textures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Dipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Dipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Dippers are responsible for the safe and efficient operation of hot dipping lines. They work in teams to ensure that products are coated to the correct specifications and that the equipment is operating properly.

1. Coating Products

Hot Dippers coat products by immersing them in a molten metal bath. They must be able to control the temperature of the bath and the speed of the line to ensure that the products are coated evenly and to the correct thickness.

- Operate hot dipping lines to coat products with molten metal.

- Control the temperature of the molten metal bath.

- Adjust the speed of the line to ensure that products are coated evenly.

- Inspect coated products to ensure that they meet specifications.

2. Equipment Maintenance

Hot Dippers are also responsible for maintaining the equipment on the hot dipping line. They must be able to troubleshoot problems and make repairs as needed. They must also keep the equipment clean and lubricated.

- Maintain and repair hot dipping equipment.

- Troubleshoot problems with the equipment.

- Clean and lubricate the equipment.

- Follow safety procedures to prevent accidents.

3. Safety

Hot Dippers work in a hazardous environment. They must be aware of the risks and take precautions to prevent accidents. They must also be able to follow safety procedures and wear appropriate personal protective equipment.

- Follow safety procedures to prevent accidents.

- Wear appropriate personal protective equipment.

- Be aware of the risks of working with molten metal.

- Take precautions to prevent burns and other injuries.

4. Other Responsibilities

Hot Dippers may also be responsible for other tasks, such as:

- Loading and unloading products from the hot dipping line.

- Packaging and storing coated products.

- Keeping records of production and maintenance activities.

- Working with other employees to ensure that the hot dipping line is operating efficiently.

Interview Tips

Preparing for an interview can be stressful, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Take some time to research the company you are interviewing with and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work for the company.

- Review the job description carefully.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Choose clothes that are comfortable and allow you to move freely.

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. Plan your route in advance and give yourself plenty of time to get to the interview location.

- Arrive on time for your interview.

- If you are running late, call the interviewer to let them know.

- Apologize for being late and explain the reason.

5. Be Yourself

The most important thing is to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic.

- Answer questions thoughtfully and completely.

- Ask questions of your own.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Dipper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Dipper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.