Are you gearing up for an interview for a Metalizer Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metalizer Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

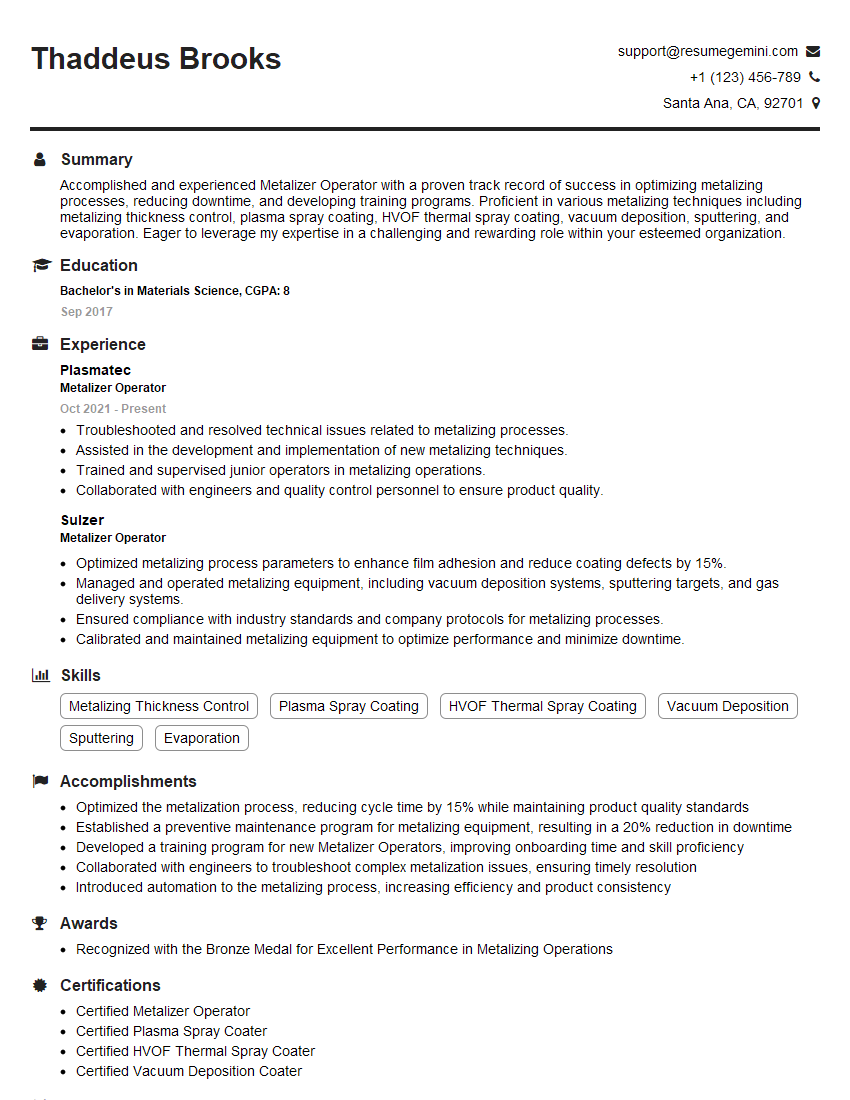

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metalizer Operator

1. Describe the process of vacuum metallizing?

Vacuum metallizing is a process where a thin layer of metal is deposited onto a surface. This is done in a vacuum chamber, where the metal is evaporated and then condenses onto the surface. The process can be used to coat a variety of materials, including plastics, metals, and glass.

- The process begins by cleaning the surface to be coated. This is done to remove any dirt or debris that could interfere with the bonding of the metal.

- The surface is then placed in a vacuum chamber. The chamber is then evacuated, removing all of the air.

- The metal to be deposited is placed in a crucible. The crucible is then heated until the metal evaporates.

- The evaporated metal atoms travel through the vacuum chamber and condense onto the surface of the object being coated.

- The thickness of the metal layer can be controlled by the amount of time that the metal is evaporated.

2. What are the different types of vacuum metallizing?

Physical Vapor Deposition (PVD)

- PVD is a process where the metal is vaporized by heating it to a high temperature.

- The vaporized metal atoms then travel through the vacuum chamber and condense onto the surface of the object being coated.

Chemical Vapor Deposition (CVD)

- CVD is a process where the metal is deposited onto the surface by a chemical reaction.

- The metal is typically heated to a high temperature and then a chemical vapor is introduced into the vacuum chamber.

3. What are the advantages and disadvantages of vacuum metallizing?

- Advantages

- Vacuum metallizing can be used to coat a wide variety of materials.

- The process can be used to produce a thin, even coating.

- The coating is durable and can withstand wear and tear.

- Disadvantages

- Vacuum metallizing can be a slow and expensive process.

- The process can be hazardous, as it involves the use of chemicals and high temperatures.

4. What are the different applications of vacuum metallizing?

- Vacuum metallizing is used in a variety of applications, including:

- Automotive parts

- Cosmetics

- Electronics

- Medical devices

- Packaging

5. What are the safety precautions that must be taken when operating a vacuum metallizing machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Operate the machine in a well-ventilated area.

- Do not touch the hot surfaces of the machine.

- Be aware of the potential for fire and explosion.

- Follow all manufacturer’s instructions for safe operation.

6. What are the troubleshooting tips for vacuum metallizing?

- If the coating is not adhering to the surface, the surface may not have been properly cleaned.

- If the coating is too thin, the metal may not have been evaporated for long enough.

- If the coating is too thick, the metal may have been evaporated for too long.

- If the coating is not uniform, the metal may not have been evenly distributed in the vacuum chamber.

7. What are the quality control procedures for vacuum metallizing?

- The thickness of the coating should be measured.

- The adhesion of the coating should be tested.

- The appearance of the coating should be inspected.

8. What are the future trends in vacuum metallizing?

- The use of new materials, such as graphene and carbon nanotubes.

- The development of new processes, such as atomic layer deposition.

- The use of vacuum metallizing in new applications, such as flexible electronics and biomedical devices.

9. What is your experience with vacuum metallizing?

- I have over 5 years of experience operating a vacuum metallizing machine.

- I am familiar with all of the safety precautions that must be taken when operating the machine.

- I have experience troubleshooting and resolving problems with the machine.

- I am proficient in all of the quality control procedures for vacuum metallizing.

10. Why should we hire you as a metalizer operator?

- I am a highly skilled and experienced vacuum metallizing operator.

- I am passionate about my work and I take pride in producing high-quality coatings.

- I am a team player and I am always willing to help out my colleagues.

- I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metalizer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metalizer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metalizer Operators are responsible for operating and maintaining metalizing equipment that applies a thin layer of metal to various surfaces. They play a crucial role in ensuring the quality and efficiency of metalized products. Key job responsibilities include:

1. Equipment Operation

Operate metalizing equipment according to established procedures to apply a thin layer of metal to surfaces.

- Set up and calibrate equipment to ensure optimal performance.

- Monitor and adjust process parameters throughout the metalizing process.

2. Material Handling

Handle and prepare materials used in the metalizing process, such as metals, evaporation sources, and substrates.

- Load and unload materials into the metalizing chamber or vacuum coating machine.

- Monitor material usage and replenish as needed to maintain production schedules.

3. Quality Control

Conduct inspections of metalized surfaces to ensure they meet specifications and quality standards.

- Use precision measuring instruments and gauges to inspect surface thickness, adhesion, and other parameters.

- Identify and resolve any defects or inconsistencies in the metalized products.

4. Maintenance and Troubleshooting

Perform regular maintenance and troubleshooting tasks to keep metalizing equipment operating efficiently.

- Clean and inspect equipment components to identify potential issues.

- Diagnose and resolve equipment malfunctions or downtime to minimize production disruptions.

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some tips to help you ace the interview for a Metalizer Operator position:

1. Research the Company and Role

Take time to research the company and the specific Metalizer Operator role you are applying for. This knowledge will help you understand the company’s culture, values, and expectations for the position.

- Visit the company’s website to learn about their products, services, and industry standing.

- Review the job description thoroughly and identify the key skills and qualifications required for the role.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your relevant experience and skills that align with the job requirements. Quantify your accomplishments using specific examples and data whenever possible.

- Describe your experience operating metalizing equipment, including the types of machines and materials you have worked with.

- Provide examples of your quality control processes and how you ensured the quality of metalized products.

3. Demonstrate Technical Knowledge

Metalizer Operators should possess a solid understanding of the technical aspects of the metalizing process. Be prepared to discuss your knowledge of:

- Different metalizing techniques, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

- Properties of various metals and their suitability for different applications.

4. Be Prepared for Behavioral Questions

Interviewers often ask behavioral questions to assess your soft skills and work style. Prepare for questions that start with “Tell me about a time when…” or “Describe a situation where…”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Focus on highlighting your problem-solving abilities, attention to detail, and teamwork skills.

5. Ask Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare a few questions that demonstrate your enthusiasm and curiosity.

- Ask about the company’s growth plans and industry trends.

- Inquire about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metalizer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!