Feeling lost in a sea of interview questions? Landed that dream interview for Seed Pelleter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Seed Pelleter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

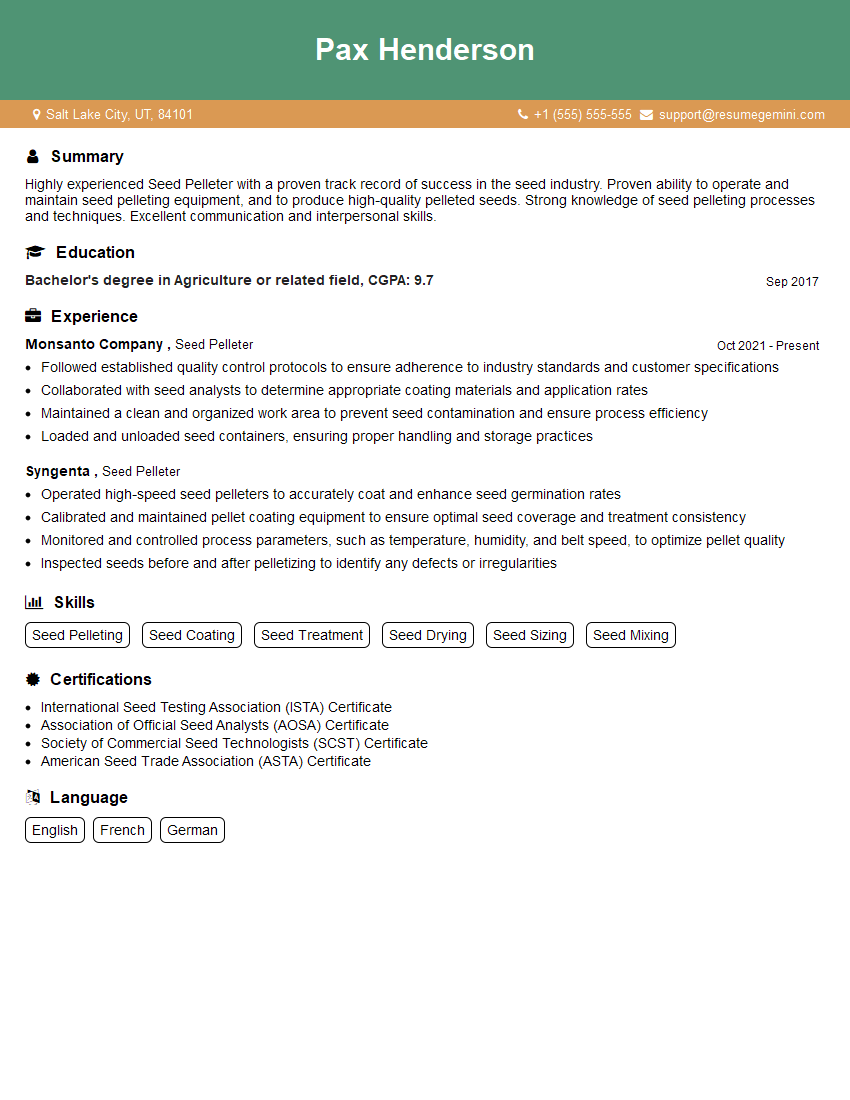

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seed Pelleter

1. Describe the process of seed pelleting.

Seed pelleting involves coating seeds with a protective layer to enhance their performance. The process typically includes the following steps:

- Seed preparation: Seeds are cleaned, graded, and treated to remove any impurities or disease-causing organisms.

- Pellet formation: Seeds are mixed with a binding agent, such as clay or polymers, to create a paste-like mixture. This mixture is then extruded through a pelletizer to form cylindrical pellets.

- Drying and coating: The pellets are dried to remove excess moisture and then coated with a protective layer, such as wax or a polymer film, to improve their durability and resistance to environmental factors.

2. What are the benefits of seed pelleting?

Seed pelleting offers numerous benefits, including:

Enhanced seed handling:

- Improved flowability and ease of planting due to the uniform size and shape of the pellets.

- Reduced dust generation and improved handling safety.

Improved seed performance:

- Better seed germination and seedling establishment due to the controlled release of moisture and nutrients from the pellet coating.

- Enhanced seed protection against pests, diseases, and environmental stresses.

Increased crop yield:

- Uniform plant spacing and improved seed placement, leading to optimal plant growth and yield.

- Reduced seed costs due to the improved seed viability and performance.

3. What factors should be considered when selecting seed pelleting materials?

When selecting seed pelleting materials, several factors should be considered:

- Seed type: Different seed types have varying requirements for pellet size, shape, and coating materials.

- Pelleting equipment: The materials should be compatible with the specific pelletizing equipment and extrusion techniques used.

- Environmental conditions: The coating materials should provide adequate protection against specific environmental stresses, such as drought, heat, or cold.

- Cost and availability: The materials should be economically viable and readily available for consistent production.

4. How do you ensure the quality of seed pellets?

Ensuring the quality of seed pellets involves implementing several quality control measures:

- Seed testing: Testing seed viability and vigor before pelleting to ensure high germination rates.

- Pellet inspection: Regular visual inspection of pellets to check for proper size, shape, and coating uniformity.

- Moisture content monitoring: Controlling the moisture content of pellets to prevent seed damage or mold growth.

- Packaging and storage: Using appropriate packaging materials and storage conditions to maintain pellet quality and longevity.

5. Explain the different types of seed pelleting equipment.

There are various types of seed pelleting equipment, each with its own advantages and applications:

Disc pelletizers:

- Suitable for small-scale pelleting operations.

- Use rotating discs to mix and form pellets.

Drum pelletizers:

- Used for larger-scale production.

- Involve rotating drums that tumble and mix the seed and pelleting materials.

Extrusion pelletizers:

- Create high-quality, uniform pellets with precise size and shape control.

- Use a screw or piston to force the seed mixture through an extrusion die.

6. How do you troubleshoot common problems encountered in seed pelleting?

Common problems in seed pelleting and their troubleshooting measures include:

Poor pellet formation:

- Check the moisture content and adjust as needed.

- Inspect the pelleting equipment for any mechanical issues.

Pellet cracking or crumbling:

- Increase the pellet moisture content slightly.

- Review the pelleting materials and adjust the binder ratio.

Seed damage:

- Avoid over-pelleting or using excessive pressure during extrusion.

- Ensure the pelleting equipment is properly calibrated.

7. Describe the different types of seed pelleting coatings.

Seed pelleting coatings vary in composition and properties:

Inorganic coatings:

- Clay and talc: Provide basic protection and improve handling.

- Carbon dust: Acts as a fungicide and enhances moisture retention.

Organic coatings:

- Polymer films: Create a waterproof barrier and protect against environmental stresses.

- Hydrocolloids: Enhance seed hydration and provide nutrients for early seedling growth.

Biocontrol coatings:

- Beneficial microorganisms: Suppress pathogens and promote plant health.

- Natural plant extracts: Act as repellents against insects and diseases.

8. Explain the importance of proper storage and handling of seed pellets.

Proper storage and handling are crucial for maintaining the viability and quality of seed pellets:

- Moisture control: Store pellets in a cool, dry environment to prevent moisture absorption and seed damage.

- Temperature regulation: Ideal storage temperatures vary depending on the pellet coating materials, but generally within a range of 10-20°C (50-68°F).

- Pest and disease control: Ensure storage facilities are free from pests and diseases that can compromise pellet integrity.

- Handling precautions: Avoid rough handling or excessive agitation to prevent pellet damage or crumbling.

9. Discuss the role of technology in advancing seed pelleting techniques.

Advancements in technology have significantly enhanced seed pelleting processes:

- Automated equipment: Computerized pelletizers and dispensers improve efficiency and precision.

- Non-destructive testing: X-ray or ultrasound technologies allow for real-time monitoring of pellet quality.

- Seed enhancement technologies: Novel coating materials and biocontrol agents improve seed performance and resistance to stresses.

10. How do you stay updated with the latest developments in seed pelleting technology?

To stay abreast of advancements in seed pelleting, I actively engage in the following practices:

- Industry publications: Subscribe to trade magazines and journals to stay informed about new techniques and research.

- Conferences and exhibitions: Attend industry events to learn from experts and network with peers.

- Online resources: Utilize websites, databases, and social media platforms to access up-to-date information.

- Collaboration: Engage in discussions with colleagues, researchers, and equipment manufacturers to share knowledge and foster innovation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seed Pelleter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seed Pelleter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Seed Pelleter plays a pivotal role in ensuring the efficient and successful production of pelleted seeds, which are crucial for modern agriculture. Their primary responsibilities encompass:

1. Seed Preparation and Pelleting

Preparing seeds for pelleting involves cleaning, grading, and treating them to enhance their quality and germination rates. They also operate and maintain pelleting machines to apply a protective coating to seeds, improving their handling, sowing precision, and field emergence.

- Cleaning and grading seeds to remove impurities and ensure uniform size.

- Applying seed treatments to protect against pests, diseases, and environmental factors.

- Operating pelleting machines to apply a precise layer of coating material to seeds.

- Monitoring and adjusting machine settings to optimize pelleting quality and efficiency.

2. Quality Control and Analysis

Ensuring the quality of pelleted seeds is paramount. Seed Pelletors conduct regular inspections and tests to assess seed viability, coating uniformity, and overall performance. They also analyze data to identify areas for improvement and maintain high standards.

- Conducting germination tests to evaluate seed viability and vigor.

- Inspecting pelleted seeds for coating defects, size variations, and other quality issues.

- Analyzing production data to identify trends and areas for improvement.

- Following established quality control protocols and industry standards.

3. Equipment Maintenance and Troubleshooting

Seed Pelletors are responsible for maintaining and troubleshooting pelleting equipment. They ensure that machines are operating optimally to avoid production disruptions and maintain efficiency.

- Performing routine maintenance tasks on pelleting machines, such as cleaning, lubrication, and calibration.

- Troubleshooting and resolving equipment malfunctions to minimize downtime.

- Collaborating with maintenance technicians for major repairs and upgrades.

- Maintaining a clean and organized work area to promote safety and efficiency.

4. Safety and Compliance

Seed Pelletors adhere to safety protocols and regulatory requirements to ensure a safe and compliant work environment. They follow proper handling procedures for chemicals and materials, wear appropriate protective gear, and maintain a clean and well-ventilated workplace.

- Following established safety protocols for handling chemicals and equipment.

- Wearing appropriate personal protective equipment, such as gloves, masks, and safety glasses.

- Maintaining a clean and well-ventilated work area to prevent dust and chemical exposure.

- Complying with industry regulations and environmental standards.

Interview Tips

Preparing for a Seed Pelleter interview requires a thorough understanding of the role’s responsibilities and the ability to articulate your skills and experience effectively. Here are some key tips to help you ace the interview:

1. Research the Industry and Company

Familiarize yourself with the seed industry, including market trends, major players, and advancements in pelleting technology. Research the company’s history, values, and specific product offerings to demonstrate your interest and knowledge.

- Read industry publications and articles to stay up-to-date on current trends.

- Visit the company’s website to learn about their products, services, and mission.

- Network with professionals in the field to gain insights and learn about potential opportunities.

2. Highlight Your Technical Skills

Emphasize your technical skills related to seed preparation, pelleting operations, and quality control. Quantify your experience whenever possible, using specific examples to demonstrate your proficiency.

- Describe your experience in operating and maintaining pelleting machines.

- Provide examples of how you have improved pelleting efficiency or quality.

- Explain your understanding of seed quality standards and testing procedures.

3. Demonstrate Your Problem-Solving Abilities

Seed Pelletors are expected to troubleshoot and resolve equipment issues effectively. Share examples of how you have identified and solved problems in a previous role, highlighting your analytical and practical skills.

- Describe a situation where you diagnosed and fixed a pelleting machine malfunction.

- Explain how you implemented a solution to improve production efficiency or reduce downtime.

- Discuss your approach to problem-solving and how you prioritize tasks.

4. Emphasize Safety and Compliance

Highlight your commitment to safety and regulatory compliance. Explain how you ensure a safe work environment and adhere to established protocols. Provide examples of your experience in handling hazardous materials and maintaining a clean and organized workplace.

- Describe your understanding of safety regulations and how you implement them in your work.

- Provide examples of how you have maintained a clean and well-ventilated work area.

- Explain how you stay up-to-date on industry best practices and compliance requirements.

5. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your engagement and interest. Prepare questions that show you have thoroughly researched the position and the company. This is also an opportunity to clarify any doubts or concerns.

- Ask about the company’s growth plans and future initiatives.

- Inquire about opportunities for professional development and training.

- Seek clarification on any aspects of the job description that you may be curious about.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Seed Pelleter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.