Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sandblaster Paint Sprayer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

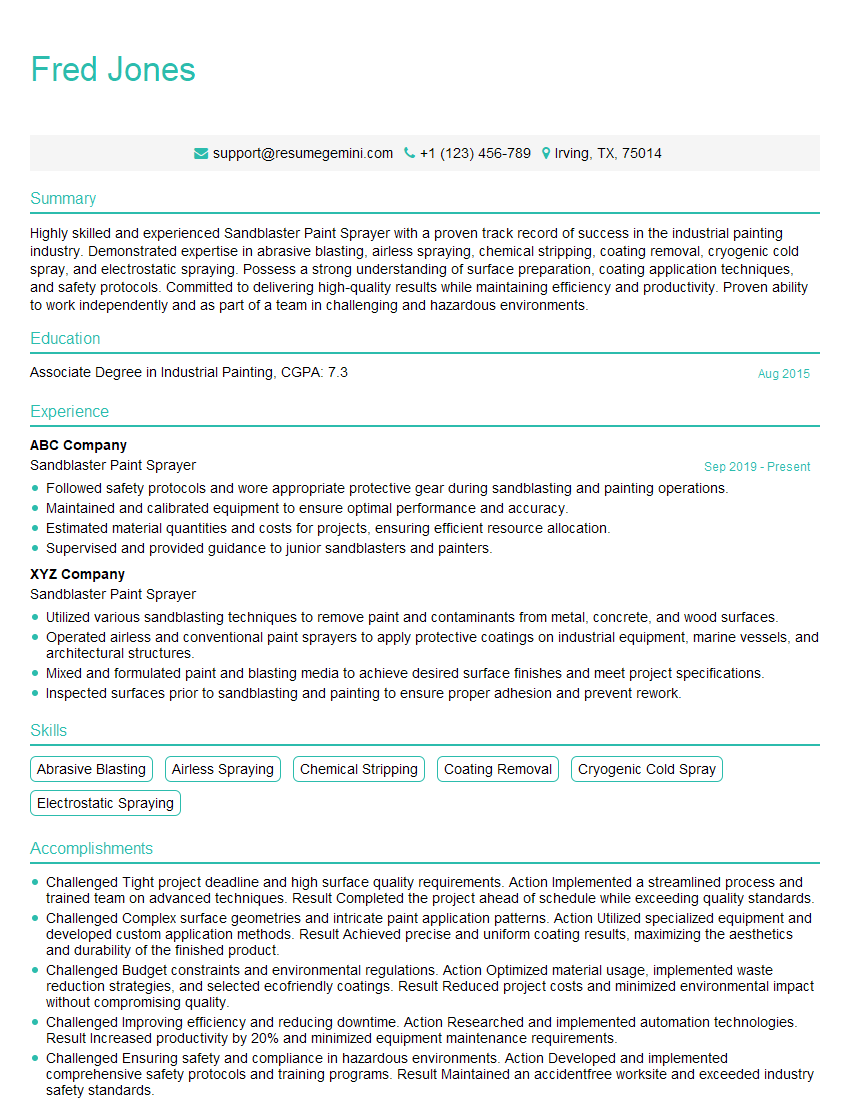

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandblaster Paint Sprayer

1. What are the different types of sandblasting equipment and their uses?

- Suction Feed Sandblaster: A suction feed sandblaster uses a venturi tube to create a vacuum that draws abrasive material from a hopper and mixes it with compressed air to propel it towards the surface being blasted.

- Pressure Feed Sandblaster: A pressure feed sandblaster uses compressed air to pressurize the abrasive material in a pressurized pot, which then forces the abrasive material through a nozzle to blast the surface.

2. Describe the safety precautions that must be taken when sandblasting.

Personal Protective Equipment (PPE)

- Respirator to prevent inhalation of dust and particles

- Eye protection to shield eyes from flying debris

- Gloves to protect hands from abrasions

- Hearing protection to reduce noise levels

Work Area Safety

- Adequate ventilation to remove dust and fumes

- Containment measures to prevent spread of abrasive material

- Proper lighting to ensure good visibility

3. What are the different types of abrasive materials used in sandblasting and their applications?

- Sand: Natural material used for general-purpose blasting, suitable for removing paint, rust, and scale.

- Aluminum Oxide: Manufactured abrasive with high hardness and durability, used for precision blasting and surface preparation.

- Glass Beads: Spherical glass particles used for delicate surfaces, such as fiberglass and plastics, to achieve a smooth finish.

- Soda: Sodium bicarbonate, a non-toxic and biodegradable abrasive used for gentle cleaning and restoration.

4. How do you determine the correct nozzle size and pressure settings for sandblasting?

- Nozzle Size: The size of the nozzle determines the width of the blast pattern and the force of the abrasive material.

- Pressure Settings: The pressure setting regulates the velocity and impact of the abrasive material. Higher pressure results in more aggressive blasting.

- Material and Surface: The type of material being blasted and the desired surface finish influence the selection of nozzle size and pressure.

5. What are the common troubleshooting issues encountered in sandblasting and how do you resolve them?

- Clogged Nozzle: Caused by abrasive material buildup. Resolve by removing and cleaning the nozzle.

- Low Abrasive Flow: Caused by insufficient air pressure or blocked feed lines. Check air supply and clear any obstructions.

- Uneven Blast Pattern: Caused by nozzle wear or misalignment. Replace or adjust the nozzle.

- Excessive Dust: Caused by poor ventilation or improper abrasive material. Ensure adequate ventilation and use the recommended abrasive.

6. How do you maintain and clean sandblasting equipment?

- Regular Cleaning: Remove abrasive material from equipment after each use to prevent clogging and wear.

- Lubrication: Lubricate moving parts regularly to ensure smooth operation and extend equipment life.

- Nozzle Inspection: Periodically check nozzles for wear or damage and replace as needed.

- Storage: Store equipment in a dry and clean location to prevent corrosion and damage.

7. What techniques can be used to achieve different surface finishes with sandblasting?

- Varying Nozzle Distance: Holding the nozzle closer results in a coarser finish, while holding it farther away creates a smoother finish.

- Angle of Impact: Blasting at a perpendicular angle produces a more aggressive finish, while blasting at an angle creates a softer finish.

- Abrasive Material Selection: Different abrasives produce different finishes, with harder abrasives resulting in a coarser finish and softer abrasives producing a smoother finish.

8. How do you estimate the amount of abrasive material needed for a sandblasting project?

- Surface Area: Calculate the total surface area of the objects being blasted.

- Material Thickness: Consider the thickness of the material and the desired depth of blasting.

- Abrasive Consumption Rate: Refer to the equipment manufacturer’s specifications or industry standards for the abrasive consumption rate per square foot of surface area.

9. What are the environmental considerations for sandblasting operations?

- Dust Control: Implement dust collection systems and proper ventilation to minimize airborne particulate matter.

- Abrasive Disposal: Dispose of spent abrasive material responsibly in accordance with local regulations.

- Noise Pollution: Use sound-dampening measures to reduce noise levels during sandblasting.

10. How do you stay up-to-date on the latest techniques and best practices in sandblasting?

- Industry Publications: Read trade magazines and journals to stay informed about advancements in equipment and techniques.

- Online Resources: Utilize industry websites, forums, and online courses to access up-to-date information.

- Training Programs: Attend industry-organized training programs to gain hands-on experience and learn from experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandblaster Paint Sprayer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandblaster Paint Sprayer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sandblasters and paint sprayers play a crucial role in the industrial and construction sectors, specializing in surface preparation and coating applications. Their responsibilities encompass:

1. Surface Preparation

Sandblasters remove rust, corrosion, paint, and other contaminants from various surfaces using abrasive blasting techniques. This includes:

- Operating sandblasting equipment, including nozzles, compressors, and abrasives

- Selecting appropriate abrasive media and pressure settings for optimal results

2. Painting and Coating

Paint sprayers apply protective or decorative coatings to surfaces using spray guns and techniques. They:

- Prepare paint materials, including mixing, thinning, and filtering

- Operate and maintain spray equipment, such as guns, hoses, and compressors

3. Equipment Maintenance

Sandblasters and paint sprayers ensure the proper functioning of their equipment by:

- Performing regular inspections and maintenance

- Troubleshooting and repairing equipment as needed

4. Safety Compliance

The job requires strict adherence to safety protocols, including:

- Wearing appropriate protective gear, such as respirators, gloves, and coveralls

- Following safety guidelines and procedures for handling hazardous materials and equipment

Interview Tips

To ace an interview for a Sandblaster Paint Sprayer position, candidates should prepare by:

1. Researching the Industry

Gaining an understanding of the industry trends, specific techniques, and safety regulations will demonstrate your interest and knowledge.

- Example: Discuss recent advancements in abrasive blasting or spray painting technologies.

2. Practicing Common Interview Questions

Anticipate and prepare for questions related to your experience, skills, and safety knowledge:

- Example: Describe your experience with using different abrasive media and techniques.

3. Demonstrating Safety Awareness

Emphasize your commitment to safety and your knowledge of industry standards and regulations.

- Example: Discuss your experience with using personal protective equipment and handling hazardous materials.

4. Highlighting Physical Capabilities

This job requires physical stamina and the ability to work in demanding conditions.

- Example: Describe how you maintain your physical fitness and handle the physical demands of the job.

5. Emphasizing Attention to Detail

Surface preparation and painting require precision and attention to detail.

- Example: Showcase your ability to follow instructions precisely and ensure high-quality results.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sandblaster Paint Sprayer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!