Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Enamel Applier interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Enamel Applier so you can tailor your answers to impress potential employers.

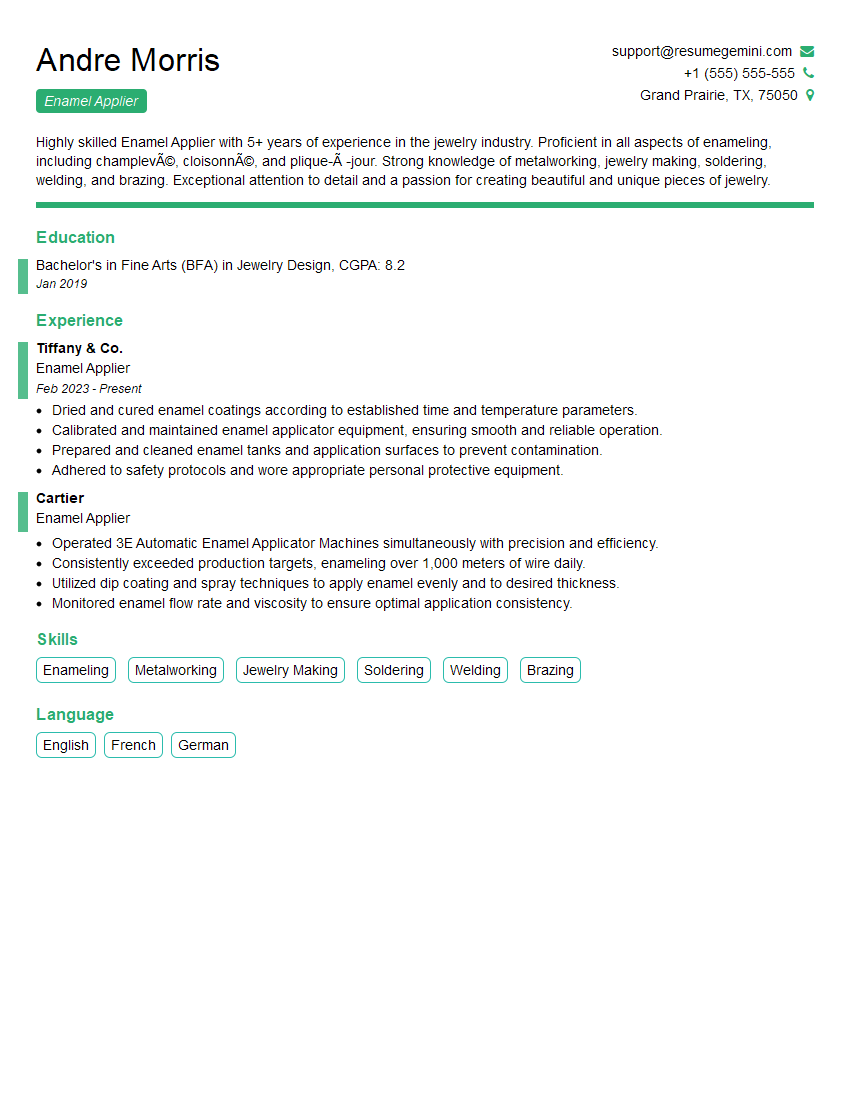

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Enamel Applier

1. How would you prepare a surface for enamel application?

To prepare a surface for enamel application, I would follow these steps:

- Clean the surface thoroughly with a degreaser to remove any dirt, oil, or grease.

- Sand the surface with a fine-grit sandpaper to create a smooth, even surface.

- Apply a primer to the surface to help the enamel adhere better.

2. What are the different types of enamel and what are their properties?

Types of Enamel

- Vitreous enamel: Made from glass and applied to metal, this type is durable, heat-resistant, and corrosion-resistant.

- Ceramic enamel: Similar to vitreous enamel but made from a ceramic material, it is highly resistant to abrasion and chemicals.

- Epoxy enamel: A two-part system consisting of epoxy resin and a curing agent, this type provides excellent resistance to moisture, chemicals, and wear.

Properties of Enamel

- Durability: Enamel is known for its exceptional durability, making it resistant to wear and tear.

- Resistance to Heat and Chemicals: It can withstand high temperatures and is not easily damaged by chemicals.

- Corrosion Resistance: Enamel provides a protective layer that prevents corrosion.

- Smooth Surface: The final finish of enamel is smooth and non-porous.

3. What are the safety precautions that should be taken when working with enamel?

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator.

- Ensure proper ventilation when working with enamel, as it can release harmful fumes.

- Avoid contact with skin, eyes, and inhalation of enamel dust.

- Handle enamel containers carefully to prevent spills or splashes.

- Dispose of enamel waste properly according to local regulations.

4. What are the common defects that can occur during enamel application and how can they be prevented?

Common Defects and Prevention Techniques

- Blisters: Caused by trapped air or moisture, they can be prevented by ensuring the surface is clean and dry before application.

- Crazing: A network of fine cracks, it can be prevented by applying multiple thin coats rather than one thick coat.

- Peeling: Occurs when the enamel loses adhesion to the surface, it can be prevented by proper surface preparation and using compatible primers.

- Discoloration: Can result from improper curing or exposure to excessive heat, it can be prevented by following manufacturer’s recommendations for curing and avoiding overheating.

- Orange Peel: A rough, dimpled surface, it can be prevented by using the correct application technique and thinning the enamel to the appropriate viscosity.

5. What are the different techniques used to apply enamel?

- Dipping: The object is submerged into a tank of liquid enamel.

- Flow Coating: The enamel is applied to the object using a spray gun or dipping method.

- Electrostatic Spraying: The enamel particles are given an electrical charge and attracted to the object.

- Brushing: The enamel is applied using a brush, typically for small or detailed areas.

- Rolling: The enamel is applied using a roller, suitable for large, flat surfaces.

6. What are the different types of equipment used in enamel application?

- Spray guns

- Dipping tanks

- Electrostatic sprayers

- Brushes

- Rollers

- Curing ovens

7. What are the factors that affect the curing time of enamel?

Factors Affecting Curing Time

- Type of enamel: Different types of enamel have different curing times.

- Temperature: Higher temperatures can decrease curing time.

- Thickness of the enamel layer: Thicker layers take longer to cure.

- Humidity: High humidity can slow down the curing process.

- Ventilation: Proper ventilation is important for the removal of fumes and moisture.

8. What are the different types of substrates that enamel can be applied to?

- Metal

- Glass

- Ceramic

- Plastic

- Wood

9. What are the advantages and disadvantages of using enamel coatings?

Advantages

- Durability

- Resistance to heat and chemicals

- Corrosion resistance

- Smooth, non-porous surface

- Aesthetic appeal

Disadvantages

- Can be expensive

- Requires specialized equipment and skills for application

- Can be brittle if not applied correctly

- Some types of enamel can release harmful fumes during curing

10. How do you ensure the quality of enamel coatings?

- Follow manufacturer’s instructions carefully.

- Use high-quality materials.

- Prepare the surface properly.

- Apply the enamel evenly.

- Cure the enamel according to the manufacturer’s recommendations.

- Inspect the finished product for any defects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Enamel Applier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Enamel Applier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Enamel Appliers are responsible for applying enamel coatings to metal surfaces, protecting them from corrosion and enhancing their appearance.

1. Surface Preparation

Prepare metal surfaces for enameling by cleaning, degreasing, and abrading.

- Inspect surfaces for imperfections and ensure they are free of contaminants.

- Use chemicals and mechanical tools to remove any existing coatings, rust, or dirt.

2. Enamel Application

Apply enamel coatings using various techniques such as dipping, spraying, or brushing.

- Choose the appropriate enamel formula and ensure it is mixed correctly.

- Apply enamel evenly and consistently, following specified thicknesses and curing temperatures.

3. Curing and Inspection

Ensure proper curing of enamel coatings by adhering to specified temperature and time parameters.

- Monitor curing processes and adjust settings as necessary to achieve optimal results.

- Inspect finished products for defects, cracks, or imperfections, and ensure they meet quality standards.

4. Maintenance and Housekeeping

Maintain equipment and work area to ensure efficient and safe operation.

- Clean and calibrate spraying equipment regularly to prevent clogs or inconsistencies.

- Maintain a clean and organized work environment to minimize contamination and promote safety.

Interview Tips

Preparing for an interview as an Enamel Applier requires thorough research and thoughtful preparation. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company’s history, values, and current projects. Understand the job description thoroughly and identify the key skills and experiences they are seeking.

- Visit the company’s website, read industry news, and check social media profiles.

- Analyze the job description and highlight your relevant qualifications.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. Practice your responses to demonstrate your knowledge, skills, and enthusiasm.

- Review industry-specific questions related to enamel application techniques and quality standards.

- Prepare examples of your experience and accomplishments that showcase your abilities.

3. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing professionally and arriving on time for your interview. Respect the interviewer’s schedule and be prepared to start the interview promptly.

- Choose attire that is appropriate for the industry and company culture.

- Plan your route in advance and allow extra time for unexpected delays.

4. Ask Informed Questions

Asking thoughtful questions during the interview shows your engagement and interest in the position. Prepare questions that demonstrate your understanding of the industry and the company’s goals.

- Inquire about the company’s current projects and the role of Enamel Appliers within those projects.

- Ask about the company’s commitment to quality and innovation.

5. Follow Up

After the interview, send a thank-you note to the interviewer reiterating your interest in the position and highlighting any key points that you want to emphasize. This gesture demonstrates your professionalism and eagerness to secure the job.

- Send a personalized email within 24 hours of the interview.

- Thank the interviewer for their time and express your enthusiasm for the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Enamel Applier, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Enamel Applier positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.