Are you gearing up for an interview for a Foam Gun Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Foam Gun Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

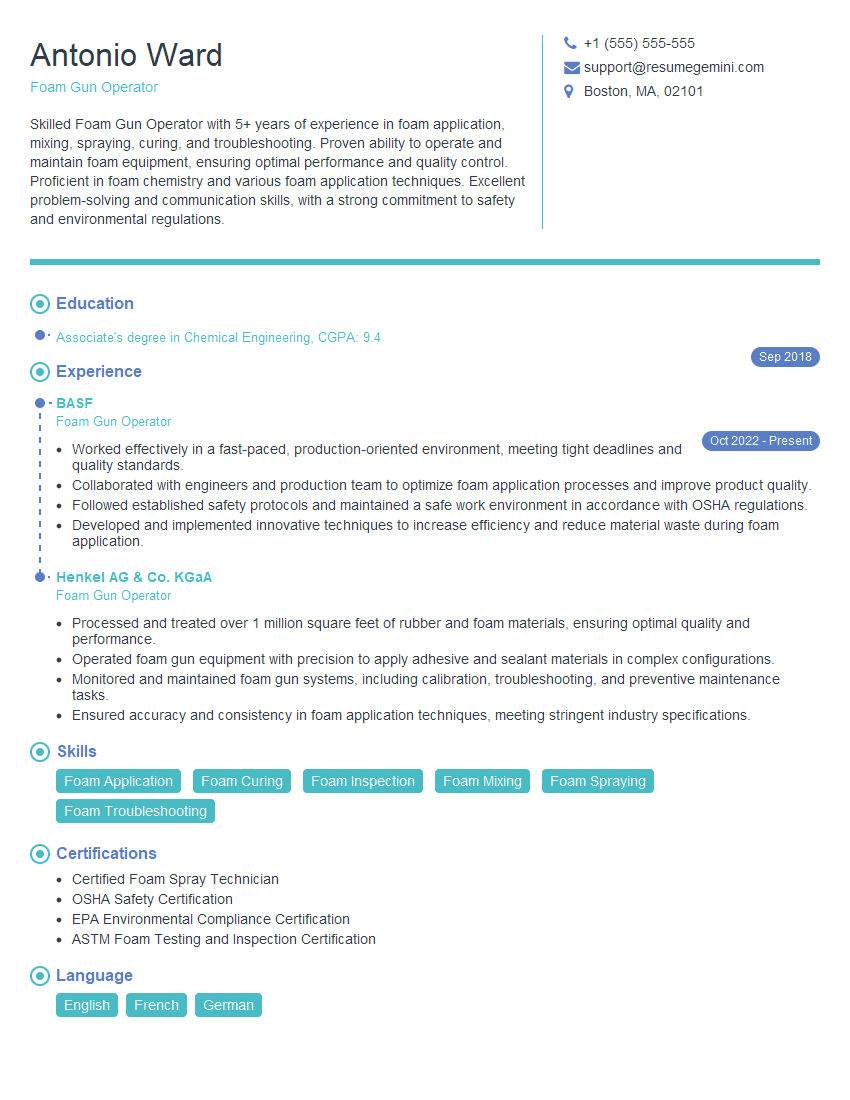

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foam Gun Operator

1. What is the standard operating procedure for calibrating and maintaining a foam gun?

The standard operating procedure for calibrating and maintaining a foam gun includes:

- Inspecting the foam gun for any damage or wear.

- Checking the foam gun’s calibration using a calibration solution.

- Adjusting the foam gun’s calibration if necessary.

- Cleaning the foam gun with a cleaning solution.

- Lubricating the foam gun with a lubricant.

- Storing the foam gun in a dry, clean location.

2. What are the different types of foam guns and what are their applications?

There are different types of foam guns, each with its own application. Some of the most common types of foam guns include:

- Handheld foam guns – These are lightweight and portable, making them ideal for small jobs or hard-to-reach areas.

- Stationary foam guns – These are larger and more powerful than handheld foam guns, and are typically used for applying foam to large surfaces or in industrial settings.

- Automatic foam guns – These are electronically controlled and can be programmed to apply foam at a specific rate or pattern.

3. What are the common troubleshooting steps for a foam gun that is not working properly?

If a foam gun is not working properly, there are a few common troubleshooting steps that can be taken:

- Check the foam gun’s power supply to make sure it is connected and turned on.

- Check the foam gun’s water supply to make sure it is connected and turned on.

- Check the foam gun’s nozzles to make sure they are not clogged.

- Check the foam gun’s filter to make sure it is not clogged.

- Check the foam gun’s pump to make sure it is working properly.

4. What are the safety precautions that should be taken when using a foam gun?

When using a foam gun, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator.

- Do not point the foam gun at anyone or anything you do not intend to foam.

- Do not use the foam gun in an enclosed area.

- Do not use the foam gun on electrical equipment.

- Do not use the foam gun on hot surfaces.

5. What are the different types of foam that can be used with a foam gun?

There are many different types of foam that can be used with a foam gun, each with its own unique properties. Some of the most common types of foam include:

- Polyurethane foam – This is a versatile foam that can be used for a variety of applications, including insulation, soundproofing, and packaging.

- Polystyrene foam – This is a lightweight and inexpensive foam that is often used for packaging and insulation.

- Polyethylene foam – This is a closed-cell foam that is resistant to water and chemicals, making it ideal for applications such as flotation and cushioning.

6. What are the different techniques for applying foam with a foam gun?

There are different techniques for applying foam with a foam gun, depending on the desired effect. Some of the most common techniques include:

- Spraying – This is the most common technique for applying foam, and it is used to create a smooth, even coating.

- Brushing – This technique is used to apply foam to small areas or to create a textured finish.

- Rolling – This technique is used to apply foam to large areas, and it is similar to painting.

7. How do you calculate the amount of foam needed for a specific job?

The amount of foam needed for a specific job depends on the size of the area to be foamed, the thickness of the foam, and the density of the foam. To calculate the amount of foam needed, you can use the following formula:

Volume of foam = Area to be foamed * Thickness of foam * Density of foam

8. What are the different factors that can affect the quality of the foam applied with a foam gun?

The quality of the foam applied with a foam gun can be affected by a number of factors, including:

- The type of foam used.

- The temperature of the foam.

- The humidity of the air.

- The technique used to apply the foam.

- The equipment used to apply the foam.

9. How do you clean and maintain a foam gun?

To clean and maintain a foam gun, you should:

- Rinse the foam gun with water after each use.

- Clean the foam gun’s nozzles and filter regularly.

- Lubricate the foam gun’s moving parts regularly.

- Store the foam gun in a dry, clean location.

10. What are some of the common problems that can occur with a foam gun and how can they be fixed?

Some of the common problems that can occur with a foam gun include:

- Clogged nozzles – Clogged nozzles can be caused by dirt, debris, or dried foam. To fix clogged nozzles, you can use a wire or a brush to clean them out.

- Leaking pump – A leaking pump can be caused by worn seals or gaskets. To fix a leaking pump, you can replace the seals or gaskets.

- Motor not running – A motor that is not running can be caused by a blown fuse or a faulty motor. To fix a motor that is not running, you can replace the fuse or the motor.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foam Gun Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foam Gun Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foam Gun Operators are responsible for operating and maintaining foam guns, which are used to apply foam insulation to buildings and other structures. They must be able to follow instructions, work independently, and troubleshoot problems. Key job responsibilities include:

1. Operating foam guns

Foam Gun Operators must be able to operate foam guns safely and efficiently. This includes following instructions, setting up the equipment, and applying foam insulation to buildings and other structures.

- Follow instructions on how to operate the foam gun.

- Set up the foam gun equipment.

- Apply foam insulation to buildings and other structures.

2. Maintaining foam guns

Foam Gun Operators must also be able to maintain foam guns. This includes cleaning the equipment, inspecting it for damage, and making repairs as needed.

- Clean the foam gun equipment.

- Inspect the foam gun for damage.

- Make repairs to the foam gun as needed.

3. Troubleshooting problems

Foam Gun Operators must be able to troubleshoot problems with foam guns. This includes identifying the problem, finding a solution, and implementing the solution.

- Identify the problem with the foam gun.

- Find a solution to the problem.

- Implement the solution to the problem.

4. Safety

Foam Gun Operators must follow all safety regulations. This includes wearing the proper safety gear, following the manufacturer’s instructions, and being aware of the hazards of working with foam insulation.

- Wear the proper safety gear.

- Follow the manufacturer’s instructions.

- Be aware of the hazards of working with foam insulation.

Interview Tips

To ace an interview for a Foam Gun Operator position, you should be prepared to answer questions about your experience with foam guns, your troubleshooting skills, and your safety knowledge. You should also be able to demonstrate your ability to follow instructions and work independently. Here are some tips for preparing for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture, the specific requirements of the position, and what the interviewer is looking for in a candidate.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice answering these questions in a clear and concise way.

- Use the STAR method to answer behavioral questions.

- Be prepared to talk about your experience with foam guns.

- Be prepared to discuss your troubleshooting skills.

3. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position they are applying for. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your abilities.

- Smile and make eye contact.

- Speak clearly and with confidence.

- Be positive and enthusiastic.

4. Ask questions

Asking questions at the end of the interview shows the interviewer that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture.

- Ask about the specific requirements of the position.

- Ask about the company’s plans for the future.

Next Step:

Now that you’re armed with the knowledge of Foam Gun Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Foam Gun Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini