Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Manugrapher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

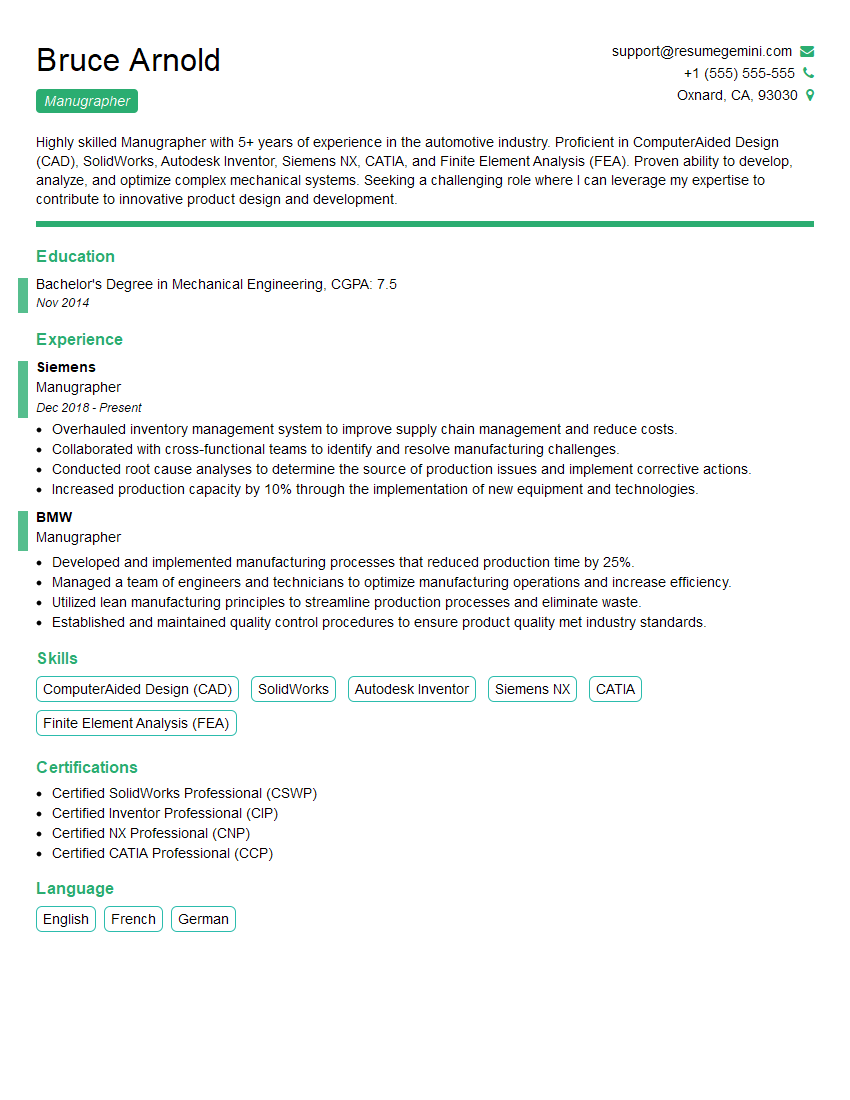

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manugrapher

1. What are the key responsibilities of a Manugrapher?

In my role as a Manugrapher, I would be involved in various responsibilities to ensure efficient manufacturing operations. Key among these responsibilities include:

- Developing and maintaining manufacturing processes to optimize production

- Supervising and coordinating production activities to ensure adherence to quality standards

- Analyzing production data to identify areas for improvement and implement corrective actions

- Managing inventory levels and ensuring efficient material flow

- Working closely with cross-functional teams, including engineering, procurement, and quality control, to ensure seamless coordination.

2. What tools and techniques do you use for production planning and scheduling?

ERP Systems

- Utilizing ERP (Enterprise Resource Planning) systems to manage production data and plan manufacturing operations

- Configuring work orders, scheduling production runs, and allocating resources based on real-time data

Scheduling Algorithms

- Applying scheduling algorithms such as First-In First-Out (FIFO), Last-In First-Out (LIFO), and Critical Path Method (CPM)

- Optimizing production schedules to minimize bottlenecks, reduce lead times, and enhance overall efficiency

Lean Manufacturing Principles

- Incorporating lean manufacturing principles to identify and eliminate waste, streamline processes, and improve production flow

- Implementing techniques such as Kanban, 5S, and Kaizen to reduce inventory levels, improve quality, and enhance overall productivity

3. How do you ensure the quality of manufactured products?

Ensuring the quality of manufactured products is paramount. I implement a comprehensive approach to quality control, including the following measures:

- Establishing clear quality standards and specifications for all products

- Implementing rigorous inspection processes at various stages of production

- Utilizing statistical process control (SPC) techniques to monitor and analyze production data

- Conducting regular quality audits to identify and address potential issues

- Collaborating with engineering and quality control teams to investigate and resolve quality concerns

4. What are the different types of manufacturing processes you are familiar with?

I am well-versed in a wide range of manufacturing processes, including:

- Machining: CNC machining, turning, milling, and grinding

- Fabrication: Welding, soldering, and assembly

- Casting: Sand casting, investment casting, and die casting

- Injection molding: Thermoplastic and thermoset molding

- Electronics assembly: Surface mount technology (SMT) and through-hole technology (THT)

5. How do you handle production issues and defects?

Handling production issues and defects is crucial to maintain efficient operations. My approach involves the following steps:

- Promptly identifying and isolating the affected products or processes

- Conducting thorough root cause analysis to determine the underlying cause of the issue

- Implementing corrective actions to address the issue and prevent recurrence

- Documenting the issue, investigation, and corrective actions for future reference

- Communicating the issue and resolution to relevant stakeholders

6. How do you manage production costs and optimize resource utilization?

Managing production costs and optimizing resource utilization is essential for profitability. I employ the following strategies:

- Analyzing production data to identify areas of waste and inefficiency

- Implementing cost-saving measures such as lean manufacturing techniques, inventory optimization, and supplier negotiations

- Automating processes to reduce labor costs and improve efficiency

- Regularly reviewing production schedules and adjusting resource allocation to minimize downtime and maximize capacity utilization

- Monitoring production costs and implementing cost control measures to stay within budget

7. What experience do you have with safety and environmental regulations in manufacturing?

Compliance with safety and environmental regulations is of utmost importance in manufacturing. I am well-versed in the following areas:

- Occupational Safety and Health Administration (OSHA) regulations

- Environmental Protection Agency (EPA) regulations

- National Fire Protection Association (NFPA) codes

- Implementing and maintaining safety protocols and procedures

- Conducting safety audits and inspections to ensure compliance

- Providing safety training to employees and contractors

8. How do you stay up-to-date with advancements in manufacturing technologies?

The manufacturing industry is constantly evolving. To stay competitive, I actively engage in the following activities:

- Attending industry conferences and webinars

- Reading technical publications and journals

- Researching and exploring emerging technologies

- Networking with peers and experts in the field

- Participating in professional development programs

9. What are your strengths and weaknesses as a Manugrapher?

Strengths:

- Strong understanding of manufacturing principles and processes

- Proven ability to optimize production and improve efficiency

- Excellent communication and interpersonal skills

- Proficient in using manufacturing software and tools

- Passionate about driving continuous improvement in manufacturing operations

Weaknesses:

- Limited experience in certain specialized manufacturing processes (specific to the industry)

- Working on developing my skills in supply chain management

10. Why are you interested in working as a Manugrapher for our company?

I am eager to join your esteemed organization as a Manugrapher for the following reasons:

- Your company is a renowned leader in the manufacturing industry, known for its commitment to innovation and quality.

- The Manugrapher role aligns perfectly with my skills, experience, and career aspirations.

- I am confident that I can contribute to your team’s success through my expertise in production planning, process optimization, and quality management.

- I am eager to learn from experienced professionals and contribute to the company’s ongoing growth and success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manugrapher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manugrapher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Manugrapher

A Manugrapher is responsible for overseeing and managing the manufacturing process within a manufacturing organization. They ensure that products are manufactured efficiently and according to specifications, quality standards, and safety regulations.

1. Production Planning and Scheduling

Plan and schedule production activities to optimize efficiency and meet customer demand.

- Develop production plans based on sales forecasts and customer orders.

- Schedule production activities, including machine utilization, labor allocation, and material procurement.

- Monitor production progress and make adjustments to ensure timely delivery.

2. Process Management

Establish and maintain manufacturing processes to ensure product quality and efficiency.

- Design and implement manufacturing processes.

- Supervise and train production personnel.

- Monitor and control production processes to ensure compliance with specifications and regulations.

3. Quality Control

Implement and maintain quality control systems to ensure product quality meets customer requirements.

- Develop and implement quality control procedures.

- Inspect and test products at various stages of production.

- Analyze quality data and identify areas for improvement.

4. Cost Control

Monitor and control manufacturing costs to optimize profitability.

- Track and analyze production costs, including materials, labor, and overhead.

- Identify and implement cost-saving measures.

- Manage vendor relationships to negotiate favorable pricing.

5. Safety Management

Maintain a safe and compliant work environment.

- Establish and implement safety procedures.

- Train and supervise employees on safety practices.

- Monitor and enforce safety regulations.

Interview Tips for a Manugrapher

To prepare for a Manugrapher interview, it’s essential to understand the role’s responsibilities and demonstrate your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will help you understand the context of the role and ask insightful questions.

2. Highlight Your Experience and Skills

Emphasize your experience in production planning, process management, quality control, cost control, and safety management. Quantify your accomplishments with specific metrics and examples.

3. Showcase Your Technical Knowledge

Demonstrate your understanding of manufacturing processes, quality standards, and industry regulations. Be prepared to discuss the latest advances in manufacturing technology.

4. Emphasize Your Leadership and Communication Skills

Manugraphers often lead and supervise teams of production personnel. Highlight your ability to motivate and communicate effectively with your team and stakeholders.

5. Be Prepared for Problem-Solving Questions

Interviewers may present hypothetical scenarios to assess your problem-solving and decision-making abilities. Be prepared to analyze situations and offer practical solutions.

6. Ask Thoughtful Questions

Asking well-thought-out questions shows your interest and engagement. It also provides an opportunity to gather additional information about the role and company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Manugrapher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!