Are you gearing up for a career in Rubber? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rubber and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

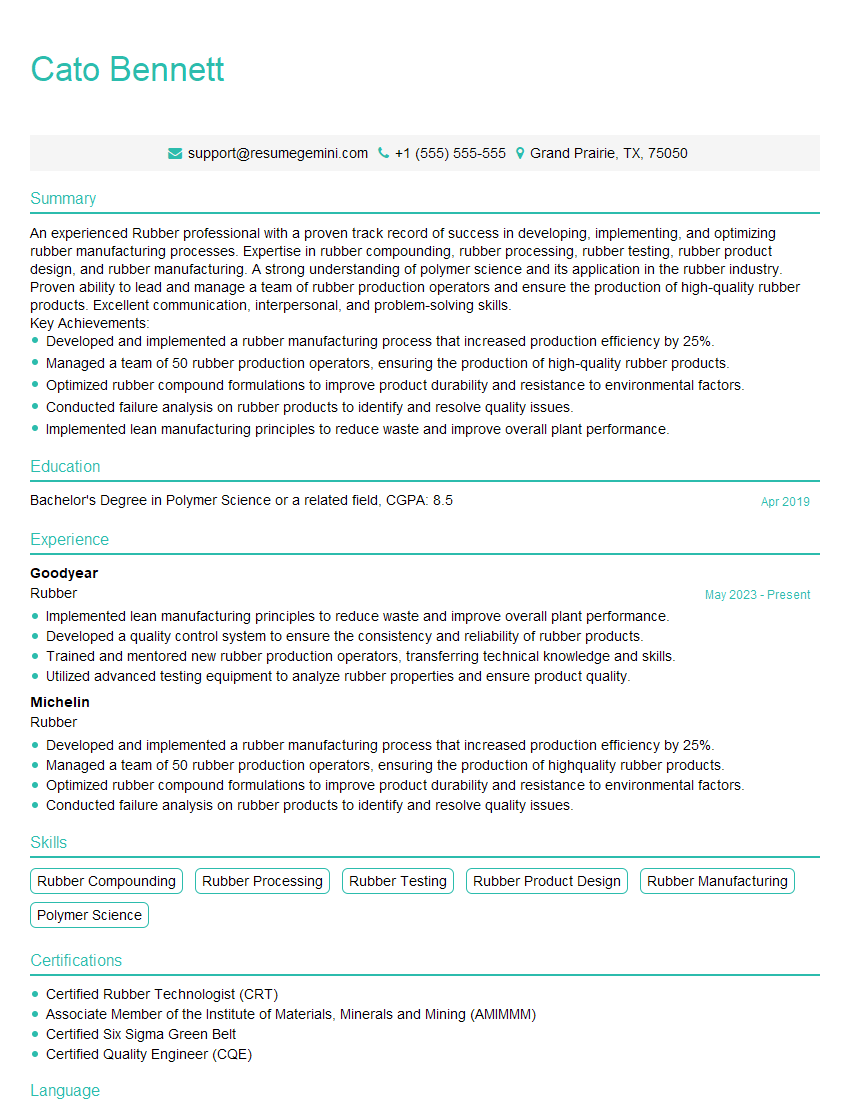

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber

1. Describe the process of vulcanization and its importance in rubber production?

Vulcanization is a chemical process that involves heating rubber with sulfur or other vulcanizing agents to improve its properties. It enhances the strength, elasticity, and durability of the rubber, making it more suitable for various applications.

- During vulcanization, the sulfur atoms form cross-links between the rubber molecules, creating a network structure.

- This cross-linking reduces the rubber’s plasticity and increases its resistance to heat, wear, and chemicals.

- Vulcanization plays a vital role in producing high-performance rubber products used in tires, hoses, seals, and other industrial applications.

2. Explain the different types of rubber compounding ingredients and their functions?

Fillers

- Fillers such as carbon black, silica, and clay improve strength, abrasion resistance, and tear resistance.

- They help reduce production costs by replacing a portion of the more expensive rubber.

Plasticizers

- Plasticizers like oils and waxes improve flexibility, softness, and workability.

- They reduce the glass transition temperature of rubber, making it more pliable at lower temperatures.

Antioxidants

- Antioxidants protect rubber from degradation caused by oxygen and ozone exposure.

- They extend the lifespan of rubber products by preventing cracking and premature failure.

3. Discuss the methods used for testing rubber properties and their significance?

Various testing methods are employed to evaluate the properties of rubber, ensuring it meets specific performance criteria.

- Tensile testing measures the rubber’s strength and elongation at break.

- Hardness testing determines the resistance of the rubber to deformation.

- Tear strength testing assesses the rubber’s ability to withstand tearing forces.

- These tests provide valuable insights into the rubber’s performance under different conditions, aiding in product development and quality control.

4. Explain the role of rubber additives in enhancing the performance of rubber products?

Rubber additives play a crucial role in modifying and improving the properties of rubber compounds.

- Antioxidants: Protect rubber from oxidation and ozone degradation, extending product life.

- Antidegradants: Counteract the effects of UV radiation, heat, and chemicals, enhancing rubber’s durability.

- Process aids: Improve rubber processing efficiency, reducing production time and costs.

- Flame retardants: Enhance fire resistance, meeting safety regulations for various applications.

5. Describe the different methods of rubber processing and their advantages?

Injection Molding

- Produces complex shapes with high precision and repeatability.

- Suitable for high-volume production of small to medium-sized parts.

Extrusion

- Creates continuous profiles, such as hoses, seals, and weatherstripping.

- Offers high production rates and versatility in shape creation.

Compression Molding

- Involves pressing rubber into a mold under heat and pressure.

- Suitable for producing large or irregularly shaped parts with high strength.

6. Discuss the factors influencing the selection of rubber for a specific application?

- Intended use: The purpose of the rubber product dictates the required properties, such as strength, flexibility, and chemical resistance.

- Environmental conditions: Factors like temperature, ozone exposure, and UV radiation influence the choice of rubber compound.

- Cost and availability: Economic considerations and the availability of different rubber types affect the selection.

- Regulatory compliance: Certain applications may have specific regulatory requirements, such as FDA approval for food-contact materials.

7. Explain the concept of rubber reinforcement and its benefits?

Rubber reinforcement involves adding fillers or reinforcing agents to enhance the properties of rubber.

- Increased strength: Fillers like carbon black and silica form strong bonds with rubber molecules, improving tensile strength and tear resistance.

- Reduced wear and abrasion: Fillers create a protective layer on the rubber surface, reducing friction and wear.

- Improved elasticity: Certain reinforcing agents, such as short fibers, enhance rubber’s elasticity and resilience.

8. Discuss the challenges and opportunities in the rubber industry?

Challenges

- Fluctuating raw material prices: Dependence on natural rubber sources can lead to price volatility.

- Environmental regulations: Stricter environmental regulations impact the disposal and recycling of rubber products.

- Competition from synthetic materials: Advancements in synthetic materials pose challenges to natural rubber.

Opportunities

- Growing demand in emerging markets: Increased industrialization and infrastructure development drive rubber consumption.

- Development of new applications: Technological advancements create new opportunities for rubber in healthcare, electronics, and renewable energy.

- Sustainability initiatives: Focus on eco-friendly and biodegradable rubber alternatives opens up new markets.

9. Explain the role of rubber in sustainable development?

- Biodegradability: Natural rubber is biodegradable, reducing environmental impact.

- Recyclability: Rubber can be recycled into new products, conserving resources.

- Emission reduction: Rubber tires contribute to fuel efficiency, reducing carbon emissions.

- Renewable resources: Natural rubber is derived from renewable sources, promoting sustainable practices.

10. Discuss the latest trends and advancements in rubber technology?

- Nanotechnology: Incorporation of nanomaterials into rubber enhances properties like strength, flexibility, and barrier resistance.

- Green rubber: Development of eco-friendly and sustainable rubber alternatives using renewable resources and biodegradable materials.

- 3D printing of rubber: Additive manufacturing techniques enable the production of complex rubber parts with greater design freedom.

- Smart rubber: Integration of sensors and electronics into rubber to create responsive and adaptive materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rubber is responsible for the production and maintenance of various rubber products. They may work in a factory or in a research and development setting. Key job responsibilities include:

1. Production

Rubber plays a vital role in the production process.

- Operate and maintain rubber processing equipment, such as extruders, mixers, and vulcanizers

- Monitor production processes to ensure quality and efficiency

- Troubleshoot and resolve production problems

2. Quality Control

Rubber is responsible for the quality control of rubber products.

- Conduct quality control tests on rubber products

- Inspect rubber products for defects

- Maintain quality control records

3. Research and Development

Rubber may also be involved in research and development.

- Develop new rubber products and processes

- Conduct research on rubber properties and applications

- Collaborate with other scientists and engineers to develop new technologies

4. Customer Service

Rubber may also be involved in customer service.

- Provide technical support to customers

- Resolve customer complaints

- Provide training on the use of rubber products

Interview Tips

To prepare for an interview for a Rubber position, you should:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals.

- Visit the company’s website

- Read articles about the company

- Talk to people who work for the company

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. You should prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering these questions with a friend or family member

- Record yourself answering these questions and watch it back

- Get feedback from a career counselor or recruiter

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Rubber. Be prepared to discuss your experience in production, quality control, research and development, and customer service. You should also be able to demonstrate your knowledge of rubber properties and applications.

- Create a resume that highlights your experience and skills

- Bring a portfolio of your work to the interview

- Be prepared to answer questions about your experience and skills

4. Dress Professionally and Be on Time

First impressions matter, so dress professionally for your interview. You should also be on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Wear a suit or business casual attire

- Be punctual for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!