Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Silk-Screen Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

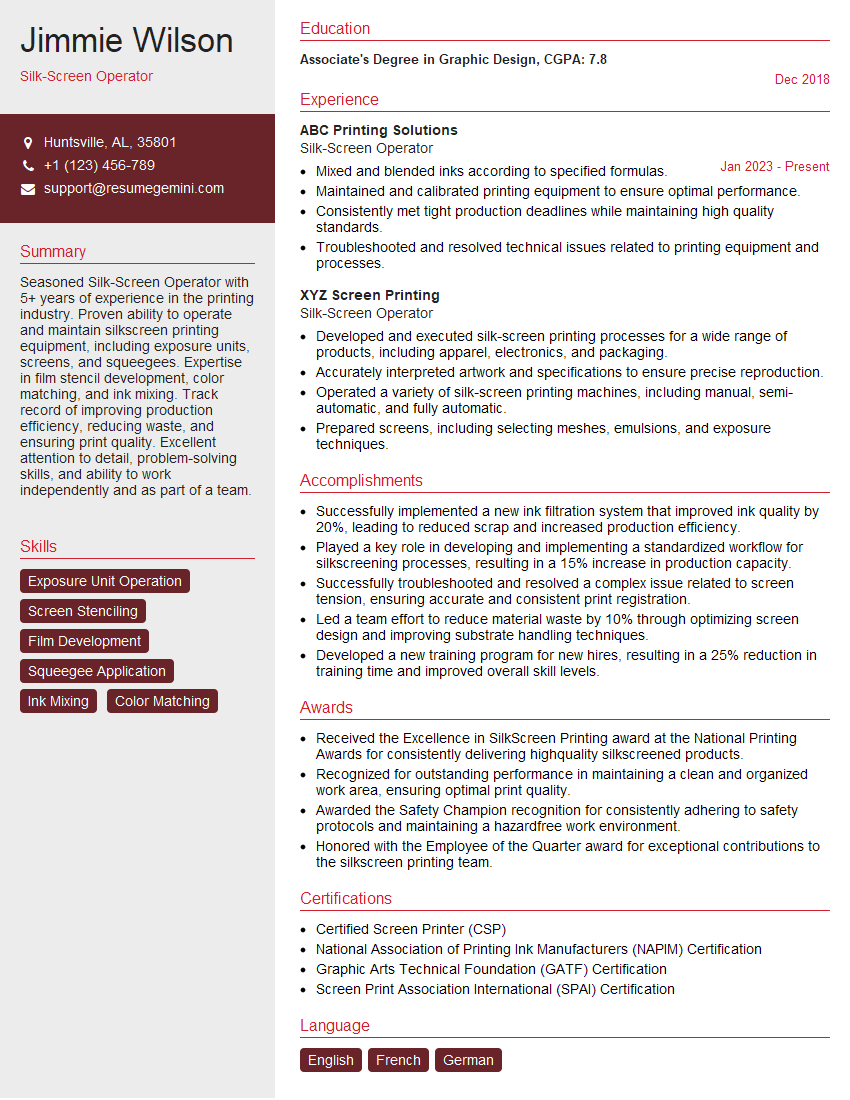

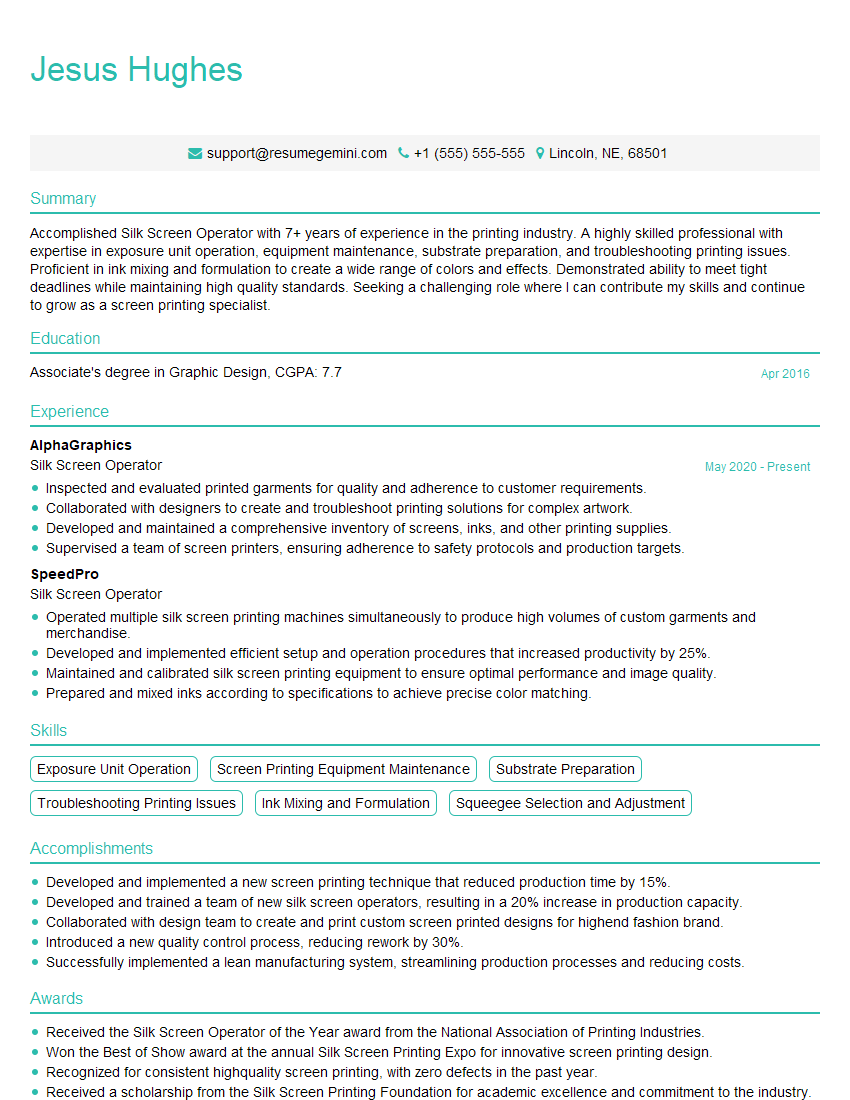

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silk-Screen Operator

1. What is the difference between a direct emulsion and an indirect emulsion?

- In a direct emulsion, the photosensitive material is applied directly to the screen, while in an indirect emulsion, it is applied to a film or paper that is then transferred to the screen.

- Direct emulsions are more durable and have a longer shelf life than indirect emulsions.

- Indirect emulsions are easier to use and produce higher quality images.

2. What are the different types of inks used in screen printing?

Water-based inks

- Water-based inks are the most common type of ink used in screen printing.

- They are non-toxic and easy to clean up.

- They are also relatively inexpensive.

Solvent-based inks

- Solvent-based inks are more durable than water-based inks.

- They are also more resistant to fading and chemicals.

- However, they are more toxic and difficult to clean up.

Plastisol inks

- Plastisol inks are made from PVC resin and plasticizers.

- They are very durable and resistant to fading and chemicals.

- However, they are also more expensive than other types of inks.

3. What are the different types of screens used in screen printing?

- Silk screens are made from a fine mesh fabric, such as silk, nylon, or polyester.

- Metal screens are made from a thin metal sheet, such as aluminum or steel.

- Plastic screens are made from a plastic sheet, such as PET or PVC.

4. What are the different types of squeegees used in screen printing?

- Hard squeegees are made from a hard material, such as plastic or metal.

- Soft squeegees are made from a soft material, such as rubber or silicone.

- The type of squeegee used depends on the type of ink and screen being used.

5. What are the different types of press used in screen printing?

- Manual presses are operated by hand.

- Semi-automatic presses are operated by a motor, but the operator still has to load and unload the screens.

- Automatic presses are fully automated and can print large quantities of prints quickly and efficiently.

6. What are the different types of curing methods used in screen printing?

- Heat curing is the most common method of curing screen prints.

- UV curing is a faster and more energy-efficient method of curing screen prints.

- Air curing is the least expensive method of curing screen prints, but it takes longer.

7. What are the different types of substrates used in screen printing?

- Textiles are the most common substrate used in screen printing.

- Paper is another common substrate used in screen printing.

- Metal, plastic, and glass can also be screen printed.

8. What are the different types of special effects that can be achieved with screen printing?

- Foiling is a process of applying a thin layer of metallic foil to a screen print.

- Flocking is a process of applying a layer of short fibers to a screen print.

- Embossing is a process of creating a raised or recessed design in a screen print.

9. What are the different troubleshooting tips for screen printing?

- If the ink is not adhering to the substrate, try using a different type of ink or a higher mesh count screen.

- If the print is blurry, try using a sharper squeegee or a slower printing speed.

- If the print is too dark, try using a less opaque ink or a lower mesh count screen.

10. What are the different safety precautions that should be taken when screen printing?

- Always wear gloves and a mask when handling inks and chemicals.

- Never eat or drink in the printing area.

- Keep the printing area well-ventilated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silk-Screen Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silk-Screen Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Silk-screen operators are responsible for the printing of designs onto various surfaces using a silk-screen printing press. Their key responsibilities include:

1. Preparing the printing press

Setting up and adjusting the printing press, including positioning the screen, loading the ink, and aligning the substrate.

- Inspecting and maintaining the printing equipment to ensure optimal performance.

- Preparing and mixing inks according to specified colors and viscosities.

2. Printing the design

Loading the substrate onto the printing press and aligning it with the screen.

- Operating the printing press to transfer the ink onto the substrate.

- Monitoring the printing process to ensure consistent quality and adherence to specifications.

3. Drying and curing the printed product

Inspecting the printed product for defects and ensuring it meets quality standards.

- Placing the printed product in a drying or curing oven to finalize the printing process.

- Maintaining a clean and organized work area to prevent contamination and ensure safety.

4. Troubleshooting and maintaining equipment

Identifying and resolving printing problems, including ink smudging, misalignment, and screen blockages.

- Performing routine maintenance and repairs on the printing press to maintain its functionality.

- Collaborating with supervisors and maintenance technicians to address complex technical issues.

Interview Tips

To ace an interview for a Silk-Screen Operator position, candidates should consider the following tips:

1. Research the company and the role

Familiarize yourself with the company’s products, services, and culture. Understand the specific requirements of the Silk-Screen Operator role and how your skills and experience align with them.

- Visit the company’s website, social media pages, and industry publications to gather information.

- Read the job description carefully and identify the key responsibilities and qualifications.

2. Highlight your technical skills and experience

Emphasize your proficiency in silk-screen printing techniques, including screen preparation, ink mixing, and press operation.

- Quantify your accomplishments by providing specific examples of your work and the results you achieved.

- Demonstrate your understanding of different printing materials, inks, and substrates.

3. Showcase your attention to detail and quality control

Silk-screen printing requires precision and attention to detail. Highlight your ability to identify and correct errors, ensuring the production of high-quality printed products.

- Describe your experience in implementing quality control procedures and adhering to industry standards.

- Explain how you maintain a clean and organized work environment to prevent contamination and defects.

4. Prepare for questions about troubleshooting and equipment maintenance

Interviewers may ask about your ability to troubleshoot printing problems and perform basic maintenance on the printing press.

- Share examples of how you have solved common printing issues, such as ink smudging or misalignment.

- Explain your understanding of the different components of the printing press and how to perform routine maintenance tasks.

Next Step:

Now that you’re armed with the knowledge of Silk-Screen Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Silk-Screen Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini