Are you gearing up for a career in Diffusion Furnace Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Diffusion Furnace Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

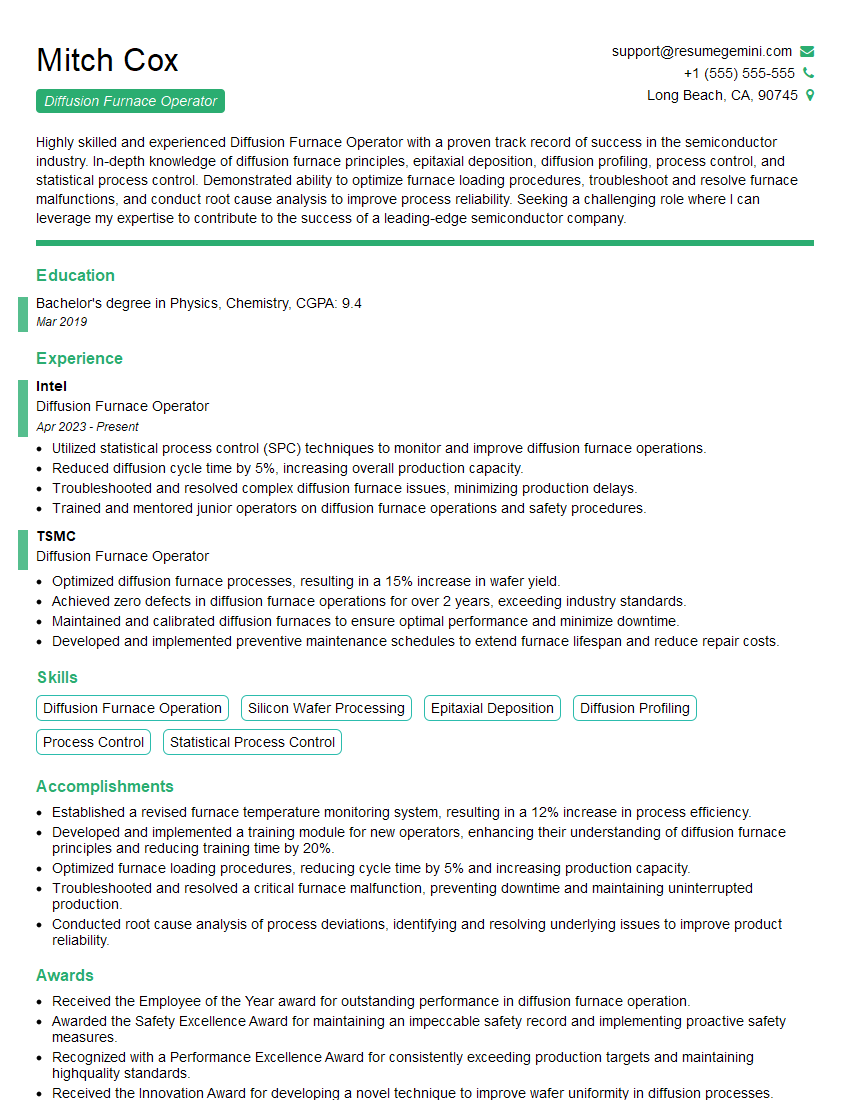

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diffusion Furnace Operator

1. what are the key responsibilities of Diffusion Furnace Operator?

- Responsible for operating and monitoring diffusion furnaces in the semiconductor manufacturing process.

- Adjusting the parameters of the furnace to achieve the desired diffusion profile

- Performing inspections of the wafers before and after diffusion

- Maintaining the furnace and its components

- Monitoring the furnace for potential problems

- Troubleshooting and resolving any issues that arise

- Keeping records of furnace operation and maintenance

- Working closely with other members of the production team

- Maintaining a clean and organized workspace

2. What are the safety precautions that must be taken when operating a diffusion furnace?

subheading of the answer

- Wearing appropriate personal protective equipment (PPE).

- Follow proper procedures for handling hazardous materials.

- Be aware of the potential hazards associated with the process.

subheading of the answer

- Knowing the location and proper use of emergency equipment.

- Receiving training on the specific hazards of the diffusion furnace being operated.

- Periodically reviewing safety procedures and attending refresher training.

3. What are the different types of diffusion furnaces?

- Batch diffusion furnaces

- Single-wafer diffusion furnaces

- Horizontal diffusion furnaces

- Vertical diffusion furnaces

- Rapid thermal annealing (RTA) furnaces

4. Explain the process of diffusion in semiconductors.

- Diffusion is the movement of atoms from a region of high concentration to a region of low concentration.

- In semiconductor manufacturing, diffusion is used to introduce dopants into the semiconductor material.

- Dopants are atoms that can change the electrical properties of the semiconductor.

- The diffusion process is carried out in a diffusion furnace.

- The wafers are placed in the furnace and heated to a high temperature.

- The dopant atoms are then introduced into the furnace and diffuse into the semiconductor material.

- The diffusion process is controlled by the temperature, the time, and the concentration of the dopant atoms.

5. what are the different types of dopants used in semiconductor manufacturing?

- Boron

- Phosphorus

- Arsenic

- Antimony

6. Explain the difference between a diffusion furnace and an oxidation furnace.

- Diffusion furnaces are used to introduce dopants into semiconductor materials.

- Oxidation furnaces are used to grow an oxide layer on the surface of semiconductor materials.

- Diffusion furnaces operate at lower temperatures than oxidation furnaces.

7. How do you calibrate a diffusion furnace?

- Place a known concentration of dopant atoms in the furnace.

- Heat the furnace to the desired diffusion temperature.

- Expose the wafers to the dopant atoms for a known period of time.

- Measure the concentration of dopant atoms in the wafers.

- Compare the measured concentration to the known concentration.

- Adjust the furnace parameters until the measured concentration matches the known concentration.

8. How do you troubleshoot a diffusion furnace?

- Check the temperature of the furnace.

- Check the flow of the dopant gas.

- Check the condition of the wafers.

- Check the condition of the furnace components.

- Consult the furnace manual.

- Contact the furnace manufacturer.

9. What are the quality control procedures that must be followed when operating a diffusion furnace?

- Monitor the furnace temperature.

- Monitor the flow of the dopant gas.

- Inspect the wafers before and after diffusion.

- Calibrate the furnace regularly.

- Maintain records of furnace operation and maintenance.

10. what are the future trends in diffusion furnace technology?

- The use of new materials.

- The use of new process technologies.

- The development of new equipment.

- The integration of diffusion furnaces with other process equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diffusion Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diffusion Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Diffusion Furnace Operator is a highly skilled professional responsible for operating and maintaining diffusion furnaces, which are used in the manufacturing of semiconductors and other electronic components. These operators play a critical role in ensuring the quality and efficiency of the diffusion process, which is essential for the production of advanced electronic devices.

1. Operating Diffusion Furnaces

Diffusion Furnace Operators are responsible for operating diffusion furnaces, which are complex and sensitive pieces of equipment. They must have a thorough understanding of the furnace’s operation, including its temperature control systems, gas flow rates, and process parameters.

- Monitor and control furnace temperature and gas flow rates to ensure optimal diffusion conditions.

- Load and unload wafers into and out of the furnace using specialized handling equipment.

- Follow established process recipes and protocols to ensure consistent and high-quality results.

2. Process Monitoring and Control

Diffusion Furnace Operators are responsible for monitoring and controlling the diffusion process to ensure that it meets specifications. They use various techniques to monitor process parameters and make adjustments as needed.

- Monitor process parameters such as temperature uniformity, gas concentrations, and wafer surface quality.

- Analyze process data and make adjustments to process parameters to optimize diffusion results.

- Troubleshoot and resolve process issues to minimize downtime and maintain production efficiency.

3. Equipment Maintenance and Calibration

Diffusion Furnace Operators are responsible for maintaining and calibrating diffusion furnaces to ensure their proper functioning. They perform regular inspections, preventive maintenance tasks, and calibrations to keep the equipment in optimal condition.

- Perform routine inspections and maintenance tasks to ensure furnace cleanliness and proper operation.

- Calibrate furnace temperature sensors and gas flow controllers to ensure accurate and reliable measurements.

- Troubleshoot and repair minor equipment issues to minimize downtime and maintain production efficiency.

4. Quality Assurance

Diffusion Furnace Operators are responsible for ensuring the quality of the wafers processed in the diffusion furnace. They perform quality checks and inspections to ensure that the wafers meet specifications and are free from defects.

- Inspect wafers for defects, contamination, and other quality issues.

- Maintain records of process parameters and quality checks for traceability and documentation purposes.

- Collaborate with quality control personnel to resolve quality issues and improve process yield.

Interview Tips

Preparing for an interview for a Diffusion Furnace Operator position requires a combination of technical knowledge, industry experience, and interpersonal skills. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific Diffusion Furnace Operator position you are applying for. This will demonstrate your interest and enthusiasm for the opportunity and help you answer questions intelligently.

- Visit the company website to learn about their products, services, and culture.

- Read industry news and publications to stay up-to-date on the latest trends and technologies.

- Identify specific aspects of the position that align with your skills and experience.

2. Practice Common Interview Questions

There are several common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare thoughtful and concise answers to these questions that highlight your relevant skills and experience.

- Practice answering questions about your technical expertise, such as your knowledge of diffusion processes and furnace operation.

- Prepare examples of your ability to troubleshoot and resolve technical issues.

- Be ready to discuss your experience with quality assurance and process improvement.

3. Showcase Your Problem-Solving Abilities

Diffusion Furnace Operators are often faced with unexpected challenges and must be able to quickly identify and resolve problems. During the interview, highlight your problem-solving skills by providing specific examples of how you have successfully addressed technical issues.

- Describe a time when you identified a problem with the diffusion furnace and implemented a solution.

- Explain how you troubleshoot and resolve process deviations to maintain production efficiency.

- Discuss your approach to continuous improvement and how you have contributed to process optimization.

4. Emphasize Your Communication and Teamwork Skills

Diffusion Furnace Operators often work as part of a team and must be able to communicate effectively with colleagues, supervisors, and customers. In the interview, highlight your communication skills and ability to work well in a team environment.

- Provide examples of your ability to communicate technical information clearly and concisely.

- Discuss your experience working in a team environment and how you contribute to team success.

- Explain how you handle conflict resolution and maintain positive relationships with colleagues.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Demonstrate your passion for the field and your eagerness to learn and grow. Dress professionally and arrive on time for your interview.

- Express your enthusiasm for the opportunity to work as a Diffusion Furnace Operator.

- Ask thoughtful questions to show your interest in the company and the position.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Diffusion Furnace Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Diffusion Furnace Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.