Feeling lost in a sea of interview questions? Landed that dream interview for Semiconductor Wafers Etcher-Stripper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Semiconductor Wafers Etcher-Stripper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

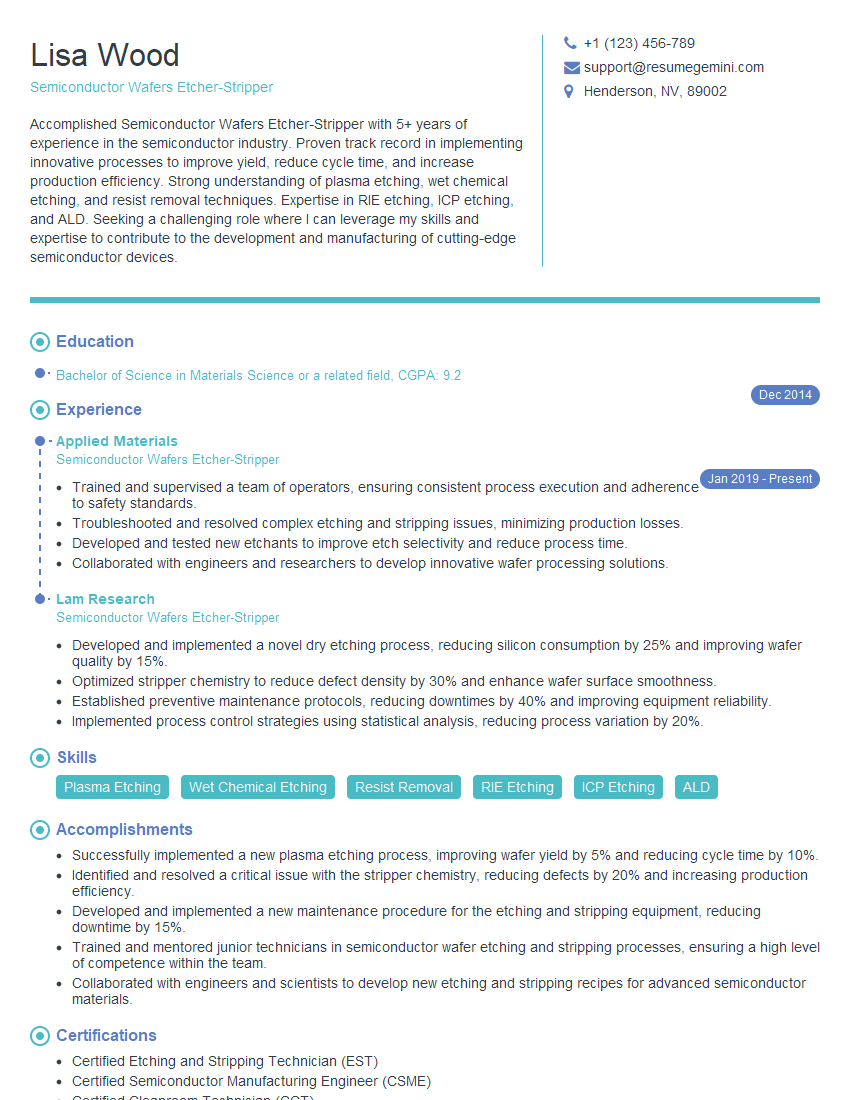

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers Etcher-Stripper

1. How would you characterize the etch rate of a silicon wafer in a reactive ion etching (RIE) system?

– Explain the factors that influence the etch rate, such as gas composition, pressure, temperature, and plasma power. – Describe the techniques used to measure the etch rate, such as ellipsometry or profilometry. – Discuss the importance of controlling the etch rate for precise device fabrication.

2. What are the different types of etchants used in semiconductor wafer processing?

Chemical Etchants

- Wet etching: Uses liquid chemicals to dissolve the semiconductor material.

- Dry etching: Involves using gases or plasma to remove material through chemical reactions.

Physical Etchants

- Sputtering: Uses physical bombardment of ions to remove material.

- Ion Milling: Similar to sputtering, but uses a focused beam of ions for precise etching.

3. How do you handle and store hazardous chemicals used in semiconductor wafer etching and stripping processes?

- Adhere to safety protocols and wear appropriate personal protective equipment (PPE).

- Store chemicals in designated areas with proper ventilation and temperature control.

- Follow waste disposal procedures to minimize environmental impact.

- Train personnel on safe handling and emergency response procedures.

4. What are the key parameters to control in a plasma etching process?

- Gas composition and flow rates.

- Plasma power and frequency.

- Substrate temperature.

- Etch time and duration.

- Pressure within the chamber.

5. Describe the role of photoresist in semiconductor wafer etching and stripping processes.

- Protects selected areas of the wafer during etching.

- Can be applied through various techniques such as spin coating or photolithography.

- Must be removed after etching using a stripping solution.

6. What are the potential defects that can occur during semiconductor wafer etching and stripping processes?

- Overetching or underetching.

- Anisotropic or isotropic etching.

- Surface roughness or contamination.

- Pattern defects or linewidth variations.

7. How do you troubleshoot and resolve common problems encountered in semiconductor wafer etching and stripping processes?

- Identify the root cause of the problem.

- Review process parameters and make adjustments as necessary.

- Calibrate and maintain equipment regularly.

- Consult with technical experts or manufacturers for support.

8. Describe the quality control procedures used to ensure the accuracy and precision of semiconductor wafer etching and stripping processes.

- Regular monitoring of process parameters.

- Inspection of etched wafers using optical or electron microscopy.

- Electrical testing to verify device performance.

- Statistical process control (SPC) to track and improve process stability.

9. What are the emerging trends and advancements in semiconductor wafer etching and stripping technologies?

- Atomic layer etching (ALE) for precise and conformal etching.

- High-aspect-ratio (HAR) etching for advanced device structures.

- Advanced materials and chemistries for improved etch selectivity.

- Integration of etching and stripping processes for reduced cycle time.

10. Describe your experience in optimizing semiconductor wafer etching and stripping processes for specific device applications.

– Highlight your understanding of the process parameters and their impact on device performance. – Provide examples of how you have successfully optimized processes to meet specific requirements. – Discuss the results and improvements achieved through your optimization efforts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers Etcher-Stripper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers Etcher-Stripper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductor Wafers Etcher-Stripper is responsible for etching and stripping semiconductor wafers in a production environment. The key job responsibilities include:

1. Etch and Strip Wafers

Operate etch and strip equipment to remove unwanted material from semiconductor wafers. Ensure that wafers meet specifications for thickness, surface roughness, and other critical parameters.

2. Maintain Etch and Strip Equipment

Perform preventive maintenance on etch and strip equipment to ensure optimal performance and minimize downtime. Troubleshoot and resolve equipment malfunctions.

3. Monitor Process Parameters

Monitor process parameters such as temperature, pressure, and chemical concentrations to ensure that wafers are processed correctly. Make adjustments as necessary to maintain process control.

4. Inspect Wafers

Inspect wafers before and after etching and stripping to verify that they meet specifications. Use optical and other inspection techniques to identify defects.

5. Maintain Cleanliness

Maintain a clean and organized work area to prevent contamination of wafers and equipment. Follow established safety protocols and wear appropriate personal protective equipment.

Interview Tips

To prepare for an interview for the position of Semiconductor Wafers Etcher-Stripper, candidates should consider the following tips:

1. Research the company and the position

Familiarize yourself with the company’s products, services, and culture. Research the specific responsibilities of the Semiconductor Wafers Etcher-Stripper position and identify the skills and experience that are required.

2. Prepare for technical questions

Expect to be asked questions about your knowledge of semiconductor processing, including etching and stripping techniques. Be prepared to discuss your experience with different types of etch and strip equipment, as well as your understanding of process parameters and control.

3. Highlight your safety awareness

Semiconductor manufacturing involves the use of hazardous chemicals and equipment. Emphasize your commitment to safety and your understanding of safety protocols and procedures.

4. Demonstrate your problem-solving skills

Interviewers will want to know how you approach and solve problems. Provide examples of how you have successfully identified and resolved equipment malfunctions or process issues in previous roles.

5. Ask thoughtful questions

Asking thoughtful questions at the end of an interview shows that you are engaged and interested in the position. Prepare questions about the company’s culture, the team you would be working with, and the opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Semiconductor Wafers Etcher-Stripper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Semiconductor Wafers Etcher-Stripper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.