Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Semiconductors Wafer Breaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

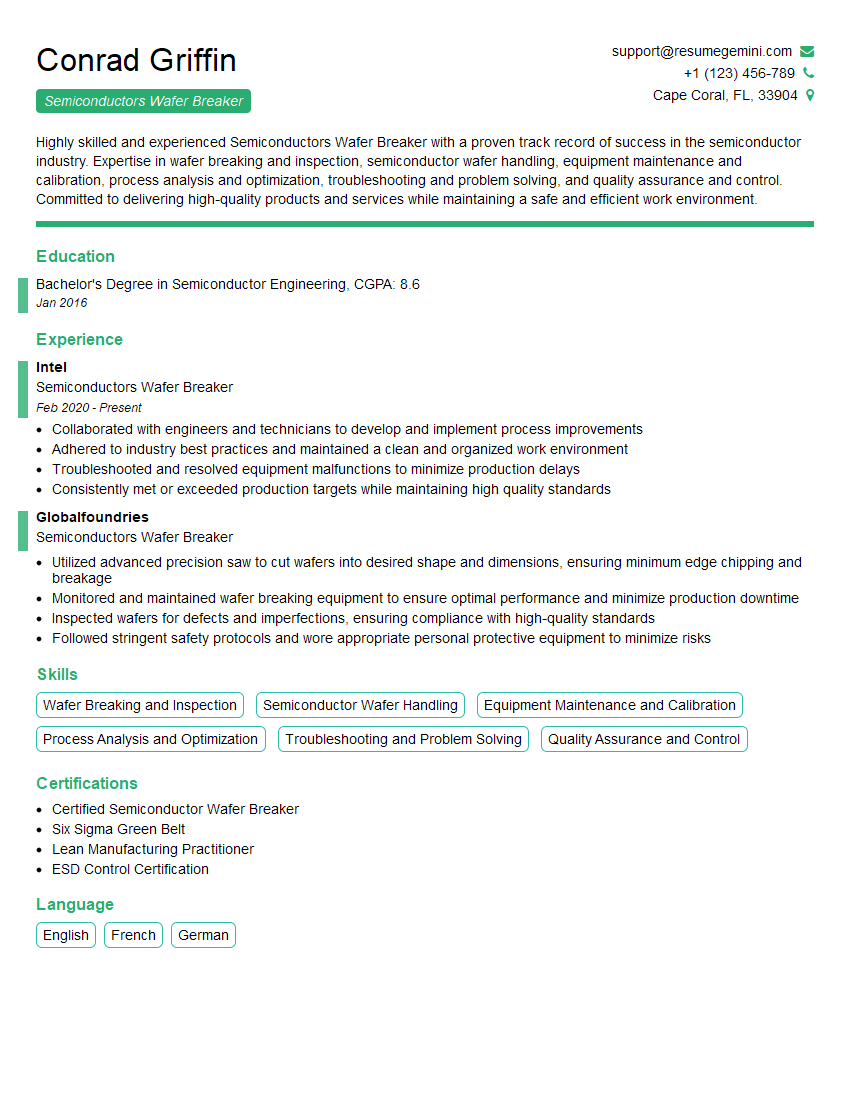

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductors Wafer Breaker

1. Describe the different methods for breaking semiconductor wafers?

There are several methods for breaking semiconductor wafers, including:

- Scoring and snapping: A scribe is used to score the wafer along a desired break line, and then the wafer is snapped apart along the score line.

- Laser cutting: A laser is used to cut the wafer along a desired break line.

- Diamond saw cutting: A diamond saw is used to cut the wafer along a desired break line.

- Waterjet cutting: A waterjet is used to cut the wafer along a desired break line.

2. What are the advantages and disadvantages of each of these methods?

The advantages and disadvantages of each wafer breaking method are as follows:

Scoring and snapping

- Advantages: Low cost, simple equipment, high precision

- Disadvantages: Can create stress in the wafer, may not be suitable for all wafer types

Laser cutting

- Advantages: Non-contact process, high precision, low stress

- Disadvantages: High cost, complex equipment, may require additional processing steps

Diamond saw cutting

- Advantages: High precision, low stress

- Disadvantages: Contact process, can create burrs, may require additional processing steps

Waterjet cutting

- Advantages: Non-contact process, low stress

- Disadvantages: Can create taper in the cut, may require additional processing steps

3. What factors should be considered when selecting a wafer breaking method?

The following factors should be considered when selecting a wafer breaking method:

- Wafer type: The type of wafer (e.g., silicon, gallium arsenide, indium phosphide) will determine which breaking methods are suitable.

- Wafer size: The size of the wafer will determine which breaking methods are feasible.

- Wafer thickness: The thickness of the wafer will determine which breaking methods are suitable.

- Desired break quality: The desired break quality (e.g., straightness, cleanliness, edge quality) will determine which breaking methods are suitable.

- Cost: The cost of the breaking method is also an important consideration.

4. How do you ensure that wafers are broken cleanly and without damage?

To ensure that wafers are broken cleanly and without damage, the following precautions should be taken:

- Use a sharp scribe or blade: A dull scribe or blade will create a rough break and may damage the wafer.

- Score the wafer lightly: Scoring the wafer too deeply will create a weak spot that may cause the wafer to break prematurely.

- Snap the wafer quickly and cleanly: Snapping the wafer slowly or hesitantly may cause the wafer to break unevenly.

- Use a cleanroom environment: Breaking wafers in a cleanroom environment will help to prevent contamination.

5. What are the common defects that can occur during wafer breaking?

The common defects that can occur during wafer breaking include:

- Chipping: Chipping occurs when small pieces of the wafer break off along the break line.

- Cracking: Cracking occurs when the wafer breaks into multiple pieces.

- Edge roughness: Edge roughness occurs when the edges of the wafer are not smooth.

- Warping: Warping occurs when the wafer is not flat after breaking.

6. How do you prevent these defects from occurring?

To prevent these defects from occurring, the following precautions should be taken:

- Use a sharp scribe or blade: A dull scribe or blade will create a rough break and may damage the wafer.

- Score the wafer lightly: Scoring the wafer too deeply will create a weak spot that may cause the wafer to break prematurely.

- Snap the wafer quickly and cleanly: Snapping the wafer slowly or hesitantly may cause the wafer to break unevenly.

- Use a cleanroom environment: Breaking wafers in a cleanroom environment will help to prevent contamination.

7. What are the safety precautions that must be taken when breaking wafers?

The following safety precautions must be taken when breaking wafers:

- Wear safety glasses: Safety glasses will protect your eyes from flying debris.

- Wear gloves: Gloves will protect your hands from sharp edges.

- Use a sharp scribe or blade: A dull scribe or blade will create a rough break and may damage the wafer.

- Score the wafer lightly: Scoring the wafer too deeply will create a weak spot that may cause the wafer to break prematurely.

- Snap the wafer quickly and cleanly: Snapping the wafer slowly or hesitantly may cause the wafer to break unevenly.

- Use a cleanroom environment: Breaking wafers in a cleanroom environment will help to prevent contamination.

8. What are the different types of wafer breaking machines?

The different types of wafer breaking machines include:

- Manual wafer breaking machines: Manual wafer breaking machines are operated by hand and are used for small-scale wafer breaking operations.

- Semi-automatic wafer breaking machines: Semi-automatic wafer breaking machines are powered by a motor and are used for medium-scale wafer breaking operations.

- Automatic wafer breaking machines: Automatic wafer breaking machines are fully automated and are used for large-scale wafer breaking operations.

9. What are the advantages and disadvantages of each type of wafer breaking machine?

The advantages and disadvantages of each type of wafer breaking machine are as follows:

Manual wafer breaking machines

- Advantages: Low cost, simple to operate

- Disadvantages: Slow, inconsistent break quality

Semi-automatic wafer breaking machines

- Advantages: Faster than manual wafer breaking machines, more consistent break quality

- Disadvantages: Higher cost than manual wafer breaking machines

Automatic wafer breaking machines

- Advantages: Fastest, most consistent break quality

- Disadvantages: Highest cost

10. How do you maintain and calibrate a wafer breaking machine?

To maintain and calibrate a wafer breaking machine, the following steps should be taken:

- Clean the machine regularly: Cleaning the machine will remove any debris that may interfere with the operation of the machine.

- Lubricate the machine regularly: Lubricating the machine will reduce friction and wear and tear.

- Calibrate the machine regularly: Calibrating the machine will ensure that the machine is breaking wafers to the correct specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductors Wafer Breaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductors Wafer Breaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductors Wafer Breaker plays a crucial role in the semiconductor manufacturing process by breaking wafers into smaller chips. This job requires meticulous attention to detail, precision, and technical knowledge.

1. Wafer Breaking

Use specialized equipment to break wafers into individual chips according to specified dimensions and tolerances.

- Adhere to safety protocols and wear appropriate personal protective equipment.

- Inspect broken chips for defects and ensure they meet quality standards.

2. Equipment Operation and Maintenance

Operate and maintain wafer breaking equipment, including dicing saws, laser cutters, and cleaving machines.

- Monitor equipment performance and troubleshoot any malfunctions.

- Perform routine maintenance tasks to ensure optimal operation.

3. Process Control and Quality Assurance

Monitor and control the wafer breaking process to ensure accuracy and efficiency.

- Adhere to established quality control procedures and standards.

- Document process parameters and maintain records for traceability.

4. Material Handling

Handle wafers and broken chips with utmost care to prevent damage.

- Follow proper handling procedures and use designated storage areas.

- Inspect wafers for any damage or defects prior to processing.

Interview Tips

Preparing for an interview for a Semiconductors Wafer Breaker position requires thorough research, practice, and a positive attitude. Here are some helpful tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends.

- Visit the company’s website and review their annual reports.

- Read industry publications and articles to gain insights into current technologies and best practices.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivations.

- “Tell us about your experience in wafer breaking.”

- “What are your strengths and weaknesses as a Semiconductors Wafer Breaker?”

3. Highlight Your Technical Skills and Knowledge

Emphasize your proficiency in operating and maintaining wafer breaking equipment and your understanding of process control techniques.

- Provide specific examples of your ability to troubleshoot equipment issues and optimize process parameters.

- Discuss your knowledge of semiconductor materials and industry standards.

4. Demonstrate Your Precision and Attention to Detail

Convey your dedication to accuracy and quality by highlighting your meticulous work style and ability to handle delicate materials.

- Share examples of your ability to consistently meet or exceed quality standards.

- Emphasize your adherence to safety protocols and your attention to detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Semiconductors Wafer Breaker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.