Are you gearing up for an interview for a Wafer Fabrication Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wafer Fabrication Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

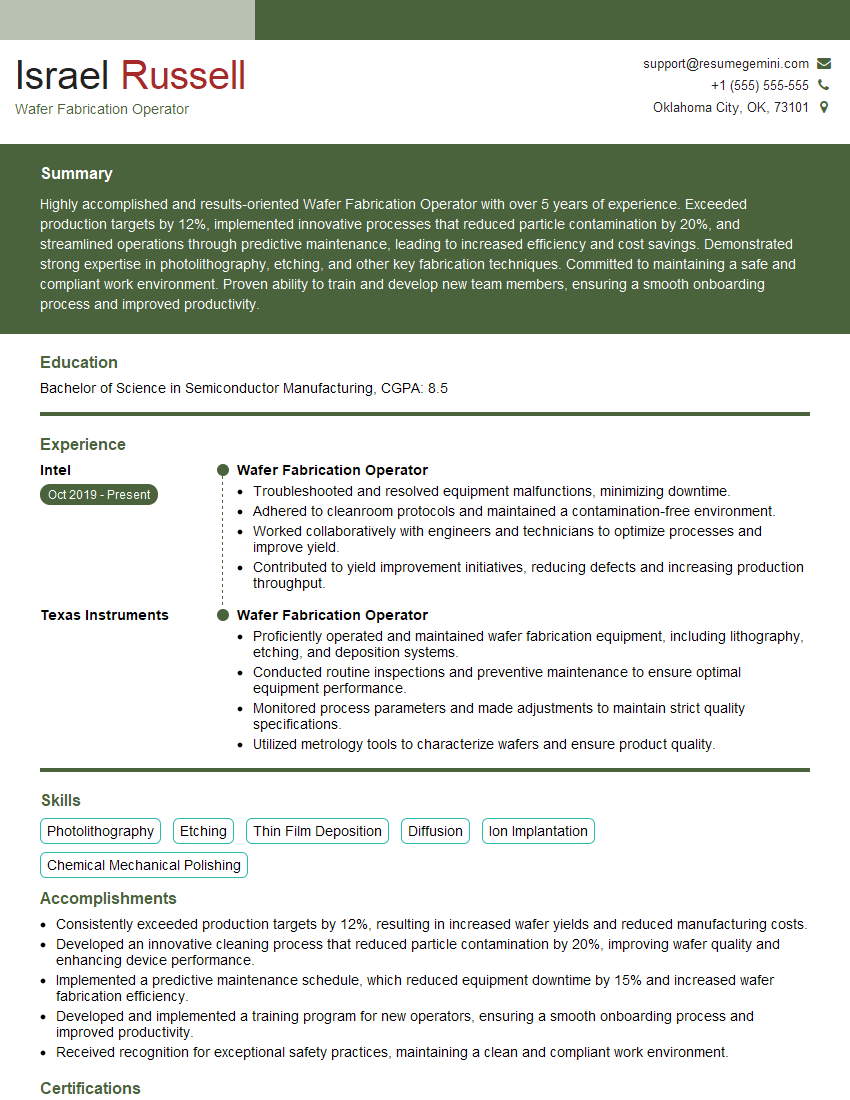

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Fabrication Operator

1. Explain the cleanroom procedures you follow while working in a wafer fabrication facility?

As a Wafer Fabrication Operator, I strictly adhere to the established cleanroom procedures to ensure a pristine and contamination-free work environment:

- Garmenting: Wear specialized cleanroom attire, including a bunny suit, gloves, and booties, to prevent the introduction of particles.

- Material Handling: Handle wafers and other sensitive materials with proper tweezers and cleanroom-approved tools to minimize contamination.

- Surface Cleaning: Use lint-free wipes and solvents to clean surfaces and equipment regularly, removing any potential particles.

- Controlled Access: Limit movement and access to minimize airflow disturbances that could carry contaminants.

- Airflow Management: Be mindful of airflow patterns and movement to prevent particle migration.

2. Describe the different types of wafer handling tools you have experience with.

- Vacuum Tweezers: Use vacuum-assisted tweezers to handle wafers gently and avoid scratching or contamination.

- Cassette-to-Cassette (CTC) Tools: Operate CTC tools to transfer wafers between cassettes, ensuring proper alignment and minimizing particle generation.

- Wafer Probers: Utilize wafer probers to test and characterize wafers, ensuring electrical integrity.

- Wafer Inspection Systems: Operate wafer inspection systems, such as optical microscopes and scanning electron microscopes, to identify defects or contamination.

- Dicing and Sawing Equipment: Handle dicing and sawing equipment to cut wafers into individual dies or chips.

3. How do you ensure the quality of wafers throughout the fabrication process?

I employ several measures to maintain wafer quality:

- Regular Inspections: Conduct visual and microscopic inspections throughout the process to detect defects or contamination.

- Environmental Monitoring: Monitor cleanroom conditions, such as temperature, humidity, and particle count, to ensure optimal fabrication environment.

- Equipment Calibration: Regularly calibrate and maintain equipment used in wafer processing to ensure accurate and consistent results.

- Process Optimization: Continuously evaluate and optimize process parameters to improve yield and minimize defects.

- Data Analysis: Analyze process data and identify trends to detect potential issues and implement corrective actions.

4. Explain the photolithography process and its importance in wafer fabrication.

Photolithography is a core process in wafer fabrication that involves the transfer of patterns onto wafers using light and a photoresist:

- Mask Preparation: Create a mask with the desired pattern.

- Photoresist Coating: Apply a light-sensitive photoresist onto the wafer.

- Exposure: Expose the photoresist to ultraviolet light through the mask, selectively hardening the exposed areas.

- Development: Develop the photoresist, removing the unexposed areas and creating the desired pattern in the photoresist.

- Pattern Transfer: Use the photoresist pattern as a mask to transfer the pattern onto the wafer using etching or deposition processes.

5. Describe the role of etching and deposition in wafer fabrication.

Etching and deposition are two essential processes in wafer fabrication:

Etching

- Removes unwanted material from the wafer surface.

- Can be isotropic (etching in all directions) or anisotropic (etching in a specific direction).

- Uses chemicals or plasma to selectively remove material.

Deposition

- Adds new material onto the wafer surface.

- Can be used to create thin films, layers, or structures.

- Uses chemical vapor deposition (CVD), physical vapor deposition (PVD), or other techniques.

6. Describe the different types of defects that can occur in wafer fabrication and how to minimize them.

- Scratches and Particles: Use proper handling techniques and minimize particle generation during cleanroom operations.

- Photoresist Defects: Optimize photolithography process parameters and ensure proper exposure and development.

- Etching Defects: Control etch parameters and monitor etch rates to prevent over-etching or under-etching.

- Deposition Defects: Use high-quality source materials and optimize deposition parameters to minimize defects.

- Electrical Defects: Implement proper grounding and electrostatic discharge (ESD) control measures.

7. Explain the importance of yield in wafer fabrication and how to improve it.

Yield refers to the percentage of wafers that meet the desired specifications:

- Defect Reduction: Minimize defects throughout the fabrication process to improve yield.

- Process Optimization: Continuously evaluate and optimize process parameters to enhance yield.

- Equipment Maintenance: Regularly maintain and calibrate equipment to ensure accurate and consistent performance.

- Statistical Process Control (SPC): Use SPC techniques to monitor and control process parameters, reducing variability and improving yield.

- Yield Analysis: Analyze yield data to identify areas for improvement and implement corrective actions.

8. Describe the different types of wafers used in wafer fabrication and their applications.

- Silicon Wafers: Most common type, used in integrated circuits (ICs), solar cells, and MEMS devices.

- Gallium Arsenide (GaAs) Wafers: Used in high-frequency electronics, optoelectronics, and solar cells.

- Indium Phosphide (InP) Wafers: Used in fiber optic communications and high-power electronics.

- Silicon Carbide (SiC) Wafers: Used in power electronics and high-temperature applications.

- Sapphire Wafers: Used in LEDs, laser diodes, and high-frequency electronics.

9. Explain the different types of process flows used in wafer fabrication.

- CMOS Process Flow: Used to fabricate complementary metal-oxide-semiconductor (CMOS) devices, the foundation of modern ICs.

- Bipolar Process Flow: Used to fabricate bipolar junction transistors (BJTs), which are used in analog circuits and power devices.

- MEMS Process Flow: Used to fabricate microelectromechanical systems (MEMS), which are devices that combine electrical and mechanical components.

- Photonic Process Flow: Used to fabricate photonic integrated circuits (PICs), which are used in optical communications and sensing.

- Power Semiconductor Process Flow: Used to fabricate power semiconductors, such as power MOSFETs and IGBTs, which are used in power electronics applications.

10. Describe the importance of metrology in wafer fabrication and the different techniques used.

Metrology is crucial for monitoring and controlling process parameters and ensuring wafer quality:

Importance

- Ensures accurate dimensions and properties of wafers and devices.

- Provides feedback for process optimization and yield improvement.

- Detects and identifies defects or non-conformities.

Techniques

- Ellipsometry: Measures thin film thickness.

- Atomic Force Microscopy (AFM): Characterizes surface topography.

- Scanning Electron Microscopy (SEM): Images and analyzes surface morphology.

- X-ray Diffraction (XRD): Determines crystal structure and strain.

- Electrical Testing: Measures electrical properties of wafers and devices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Fabrication Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Fabrication Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wafer Fabrication Operators are responsible for the day-to-day operations of semiconductor fabrication facilities. They work in a cleanroom environment and use specialized equipment to create and process silicon wafers, which are the foundation of all modern electronics.

1. Equipment Operation and Maintenance

Wafer Fabrication Operators are responsible for operating and maintaining a variety of equipment, including:

- Lithography machines, which are used to create patterns on the wafers

- Etching machines, which are used to remove unwanted material from the wafers

- Deposition machines, which are used to add new materials to the wafers

2. Process Control

Wafer Fabrication Operators are also responsible for monitoring and controlling the process conditions in the cleanroom. This includes:

- Temperature

- Humidity

- Particulate contamination

3. Quality Control

Wafer Fabrication Operators are responsible for performing quality control tests on the wafers. This includes:

- Visual inspection

- Electrical testing

- Particle counting

4. Safety

Wafer Fabrication Operators must adhere to strict safety protocols to protect themselves and the equipment. This includes:

- Wearing cleanroom suits and gloves

- Following proper handling procedures

- Reporting any accidents or incidents

Interview Tips

To ace an interview for a Wafer Fabrication Operator position, you should:

1. Research the company and the position

Take the time to learn about the company’s products, services, and culture. This will help you to answer questions about why you are interested in the position and how your skills and experience can benefit the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as they relate to the job requirements. Be sure to highlight any skills and experience that are relevant to the position, such as:

- Experience in a cleanroom environment

- Experience operating semiconductor fabrication equipment

- Experience in process control and quality assurance

4. Be enthusiastic and professional

The interviewer will be looking for someone who is enthusiastic about the position and the company. Be sure to show your enthusiasm and professionalism throughout the interview. This means being polite, respectful, and engaged in the conversation.

5. Ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. Be sure to ask thoughtful questions that show your interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wafer Fabrication Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!