Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wafer Fabricator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wafer Fabricator so you can tailor your answers to impress potential employers.

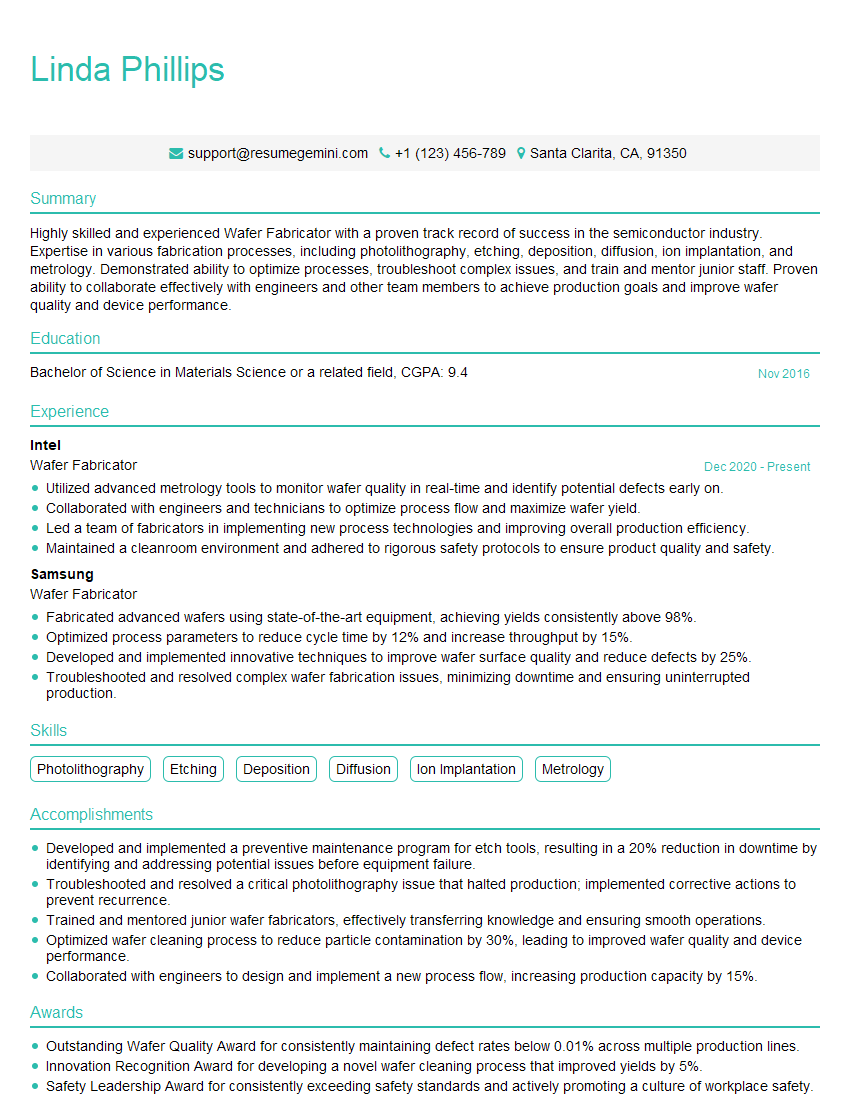

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Fabricator

1. What is the difference between a wet and dry etch?

- A wet etch is a chemical process that uses a liquid etchant to remove material from a wafer.

- A dry etch is a physical process that uses a plasma to remove material from a wafer.

2. What are the advantages and disadvantages of using a positive photoresist?

Advantages

- Positive photoresist is more resistant to overexposure than negative photoresist.

- Positive photoresist is more compatible with alkaline developers than negative photoresist.

Disadvantages

- Positive photoresist is less sensitive than negative photoresist.

- Positive photoresist is more prone to scumming than negative photoresist.

3. What is the purpose of a hard bake?

- To remove any remaining photoresist from the wafer.

- To improve the adhesion of the metal layer to the wafer.

- To increase the thermal stability of the metal layer.

4. What is the difference between a via and a contact?

- A via is a hole that connects two metal layers on a wafer.

- A contact is a hole that connects a metal layer to a semiconductor layer on a wafer.

5. What are the different types of wafer inspection?

- Visual inspection

- Optical inspection

- Electrical inspection

6. What are the most common defects found in wafers?

- Scratches

- Particles

- Voids

- Pin holes

7. What are the different types of wafer cleaning?

- Wet cleaning

- Dry cleaning

- Plasma cleaning

8. What are the different types of wafer bonding?

- Anodic bonding

- Thermal bonding

- Eutectic bonding

- Glass frit bonding

9. What are the different types of wafer thinning?

- Mechanical thinning

- Chemical thinning

- Plasma thinning

10. What are the different types of wafer dicing?

- Mechanical dicing

- Laser dicing

- Plasma dicing

- Waterjet dicing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

Wafer Fabricators are responsible for ensuring the smooth operation and maintenance of wafer fabrication equipment, ensuring the production of high-quality semiconductor wafers. Their key responsibilities include:

1. Equipment Operation and Maintenance:

Operate and maintain a variety of wafer fabrication equipment, including deposition, etching, and lithography machines.

- Monitor equipment performance, identify potential issues, and take corrective actions to prevent breakdowns.

- Perform routine maintenance and calibration to ensure equipment accuracy and precision.

2. Process Control:

Control and monitor wafer fabrication processes to ensure product quality and yield.

- Develop and implement process recipes for wafer fabrication.

- Monitor process parameters, such as temperature, pressure, and flow rates, to ensure compliance with specifications.

3. Quality Control:

Inspect and test wafers throughout the fabrication process to identify and resolve defects.

- Perform visual inspections, electrical tests, and other quality control procedures.

- Analyze inspection data to identify trends and root causes of defects.

4. Safety and Compliance:

Ensure compliance with safety regulations and environmental standards in the wafer fabrication area.

- Follow established safety protocols for handling hazardous materials.

- Maintain a clean and organized work environment to prevent contamination.

5. Troubleshooting and Problem-Solving:

Diagnose and resolve issues that arise during wafer fabrication.

- Analyze equipment logs and data to identify potential problems.

- Implement corrective measures to restore equipment to proper operating condition.

Interview Tips:

To ace the interview for a Wafer Fabricator position, preparation is key. Here are some tips to help you stand out:

1. Research the Company and Position:

Thoroughly research the company you are applying to and the specific role you are interviewing for. Understand the company’s products, culture, and mission.

- Review the job description and identify the key responsibilities and requirements.

- Visit the company’s website and social media pages to gather information about their latest projects and initiatives.

2. Highlight Your Technical Skills:

Emphasize your technical skills and experience in wafer fabrication. Provide specific examples of your work and how you have contributed to successful projects.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your contributions.

- Be prepared to discuss your knowledge of wafer fabrication equipment, processes, and quality control procedures.

3. Demonstrate Problem-Solving Abilities:

Showcase your problem-solving skills and ability to troubleshoot issues in a fast-paced environment.

- Share examples of how you have successfully diagnosed and resolved technical problems in previous roles.

- Explain your approach to troubleshooting and how you prioritize actions based on potential impact.

4. Emphasize Safety and Compliance:

Highlight your commitment to safety and compliance in the wafer fabrication environment.

- Describe your experience with following safety protocols and handling hazardous materials.

- Explain how you contribute to maintaining a clean and organized work area to prevent contamination.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wafer Fabricator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.