Are you gearing up for an interview for a Film Drying Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Film Drying Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

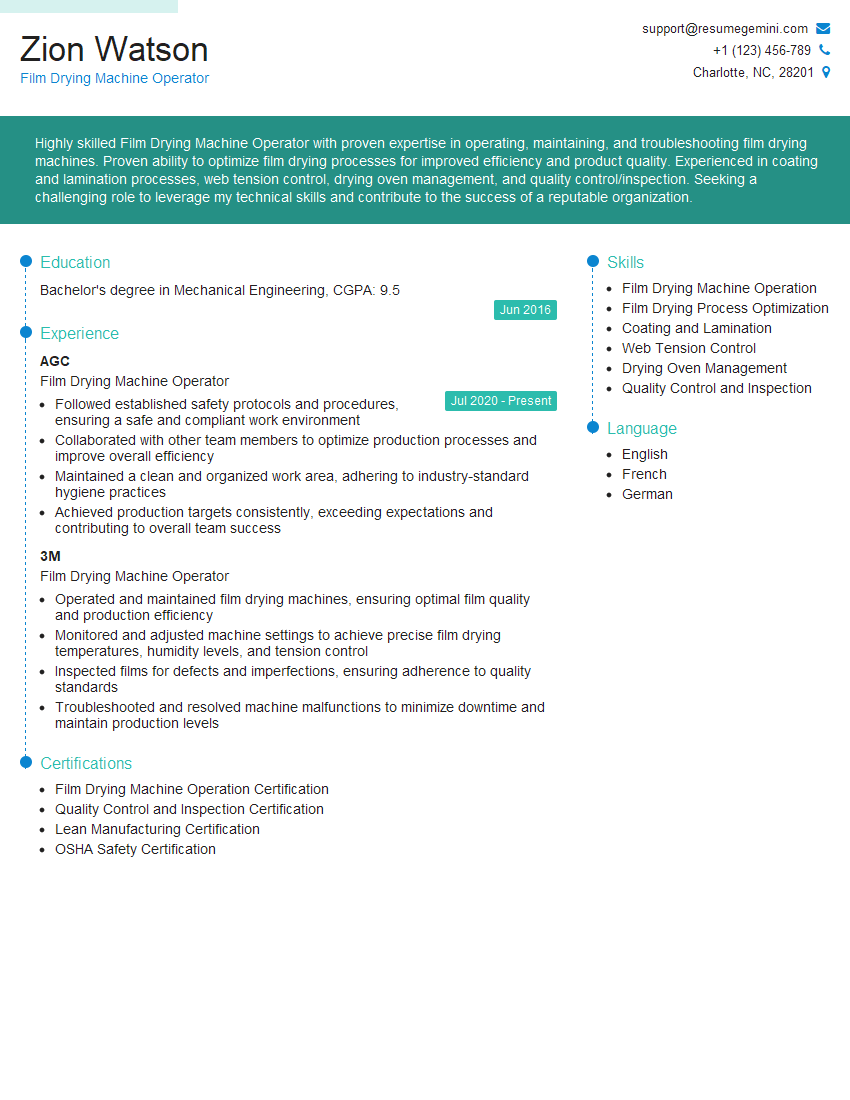

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Film Drying Machine Operator

1. Describe the process of operating a film drying machine.

The process of operating a film drying machine involves several steps:

- Loading the film: The film is loaded onto the machine’s conveyor belt by hand or using a loading mechanism.

- Setting the drying parameters: The operator sets the drying temperature, speed, and other parameters based on the film type and desired results.

- Initiating the drying process: The operator starts the machine, which moves the film through the drying chamber.

- Monitoring the drying process: The operator monitors the film’s progress through the machine and makes adjustments as needed to ensure proper drying.

- Unloading the dried film: Once the film is sufficiently dry, the operator unloads it from the machine.

2. What are the different types of film drying machines?

Conveyor-type machines

- These machines use a conveyor belt to transport the film through the drying chamber.

- They are suitable for high-volume production of films.

Batch-type machines

- These machines dry film in batches rather than continuously.

- They are used for smaller production runs or for specialty films.

3. How do you maintain a film drying machine?

To maintain a film drying machine, the operator should perform the following tasks:

- Regular cleaning: The machine should be cleaned regularly to remove any dirt or debris that may accumulate.

- Lubrication: The machine’s moving parts should be lubricated as per the manufacturer’s instructions.

- Belt inspection: The conveyor belt should be inspected regularly for wear or damage.

- Filter replacement: The machine’s filters should be replaced regularly to ensure optimal airflow.

- Calibration: The machine should be calibrated periodically to ensure accuracy in temperature and speed.

4. What is the importance of maintaining proper tension on the film during the drying process?

Maintaining proper tension on the film during the drying process is crucial for several reasons:

- Even drying: Proper tension ensures that the film is evenly dried, preventing wrinkles or distortions.

- Reduced damage: Excessive tension can cause the film to tear or stretch, while insufficient tension can lead to film buckling.

- Maximum efficiency: Proper tension allows the film to move smoothly through the machine, maximizing efficiency.

5. How do you adjust the drying temperature of a film drying machine?

To adjust the drying temperature of a film drying machine, the operator can follow these steps:

- Locate the temperature control panel on the machine.

- Set the desired temperature using the buttons or dials provided.

- Monitor the actual temperature using the digital or analog display.

- Fine-tune the temperature as needed to achieve the optimum drying conditions for the specific film.

6. What factors can affect the drying time of a film?

The drying time of a film can be influenced by several factors, including:

- Film thickness: Thicker films generally take longer to dry.

- Film material: Different film materials have varying drying rates.

- Drying temperature: Higher temperatures result in faster drying times.

- Airflow rate: Increased airflow helps evaporate moisture more quickly.

- Humidity: High humidity can slow down the drying process.

7. How do you troubleshoot common problems with a film drying machine?

To troubleshoot common problems with a film drying machine, the operator can follow these steps:

- Identify the problem: Determine the specific issue with the machine, such as uneven drying, wrinkles, or excessive moisture.

- Check for mechanical issues: Inspect the machine for any loose parts or malfunctions.

- Check the settings: Ensure that the temperature, speed, and tension settings are appropriate for the film being dried.

- Clean the machine: Remove any dirt or debris that may be obstructing airflow or causing film damage.

- Calibrate the machine: Verify the accuracy of the temperature and speed controls.

8. What safety precautions should be taken when operating a film drying machine?

When operating a film drying machine, the operator should adhere to the following safety precautions:

- Wear protective gear: Use gloves, safety glasses, and appropriate clothing to protect from heat and chemicals.

- Follow proper lockout/tagout procedures: Ensure the machine is properly isolated before performing maintenance or repairs.

- Be aware of potential hazards: Identify areas of high heat, moving parts, and electrical hazards.

- Handle chemicals safely: If using any chemicals for cleaning or maintenance, follow the manufacturer’s instructions and wear appropriate PPE.

- Report any issues promptly: Immediately inform the supervisor of any malfunctions or safety concerns.

9. Describe the different types of films that can be processed using a film drying machine.

A film drying machine can process various types of films, including:

- Polyester films: Commonly used in packaging, photographic, and industrial applications.

- Polypropylene films: Known for their strength and moisture resistance, used in food packaging and other industries.

- Polyethylene films: Versatile films with low friction and high impact resistance, used in packaging, construction, and agriculture.

- Polycarbonate films: Strong and transparent films with high temperature resistance, used in optical and automotive applications.

- Specialized films: Including metalized films for electrical insulation and conductive films for electronics.

10. What is the role of quality control in the film drying process?

Quality control plays a vital role in the film drying process to ensure the production of defect-free films.

- Sample testing: Periodically testing film samples to verify compliance with quality standards.

- Visual inspection: Checking for wrinkles, scratches, or other defects on the dried film.

- Dimensional measurements: Ensuring that the film meets the specified dimensions and tolerances.

- Moisture content analysis: Verifying that the film has the appropriate moisture content for its intended use.

- Feedback and corrective actions: Identifying areas for improvement in the drying process based on quality control results and implementing corrective measures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Film Drying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Film Drying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Film Drying Machine Operators are responsible for operating and maintaining film drying machines in the production process. They ensure that the film is dried to the correct specifications and that the machine is running efficiently.

1. Operate Film Drying Machine

Involves monitoring and controlling the operation of the film drying machine. The operator adjusts settings such as temperature, speed, and tension to ensure that the film is dried to the desired quality and specifications.

- Loading and unloading film reels

- Monitoring temperature and humidity levels

- Adjusting machine settings to optimize drying efficiency

2. Maintain Film Drying Machine

Operators perform routine maintenance and repairs to keep the film drying machine in good working order. This includes cleaning, lubrication, and replacing worn parts.

- Lubricating moving parts

- Replacing worn belts and filters

- Troubleshooting and resolving minor malfunctions

3. Monitor Film Quality

Operators visually inspect the dried film for defects such as wrinkles, tears, or uneven drying. They also use quality control instruments to measure film thickness, moisture content, and other parameters.

- Inspecting film for defects

- Measuring film thickness and moisture content

- Ensuring film meets quality standards

4. Follow Safety Protocols

Operators adhere to established safety protocols to minimize risks associated with operating and maintaining film drying machines. This includes wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Maintaining a clean and organized work area

Interview Tips

Preparing thoroughly for a Film Drying Machine Operator interview can significantly enhance your chances of making a positive impression and securing the position. Here are some crucial tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. Familiarize yourself with their products, services, company culture, and the specific responsibilities of the Film Drying Machine Operator role.

- Visit the company’s website and social media pages

- Read industry news and articles related to the company

- Identify the key skills and qualifications required for the position

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your relevant skills and experience. Practice answering questions related to your experience operating and maintaining film drying machines, your understanding of film drying processes, and your ability to work effectively in a production environment.

- Describe your experience operating and maintaining film drying machines

- Explain how you ensure that the film is dried to the correct specifications

- Discuss your understanding of the different types of film drying machines

3. Highlight Your Attention to Detail and Quality

Emphasize your strong attention to detail and commitment to quality. Film drying requires precision and accuracy, so highlight your ability to monitor and control the drying process effectively. Provide examples of your experience in visually inspecting film for defects and using quality control instruments to ensure that the film meets the required standards.

- Describe your experience in visually inspecting film for defects

- Explain how you use quality control instruments to measure film thickness and moisture content

- Discuss your commitment to maintaining high-quality standards

4. Showcase Your Problem-Solving Abilities

Interviewers are interested in candidates who can identify and resolve problems effectively. Share examples of situations where you encountered problems while operating or maintaining film drying machines and how you successfully resolved them. This demonstrates your analytical thinking skills, resourcefulness, and ability to handle challenges.

- Describe a situation where you encountered a problem while operating a film drying machine

- Explain how you diagnosed the problem and developed a solution

- Discuss the steps you took to resolve the problem and ensure smooth operation

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Film Drying Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!