Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rectification Printer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

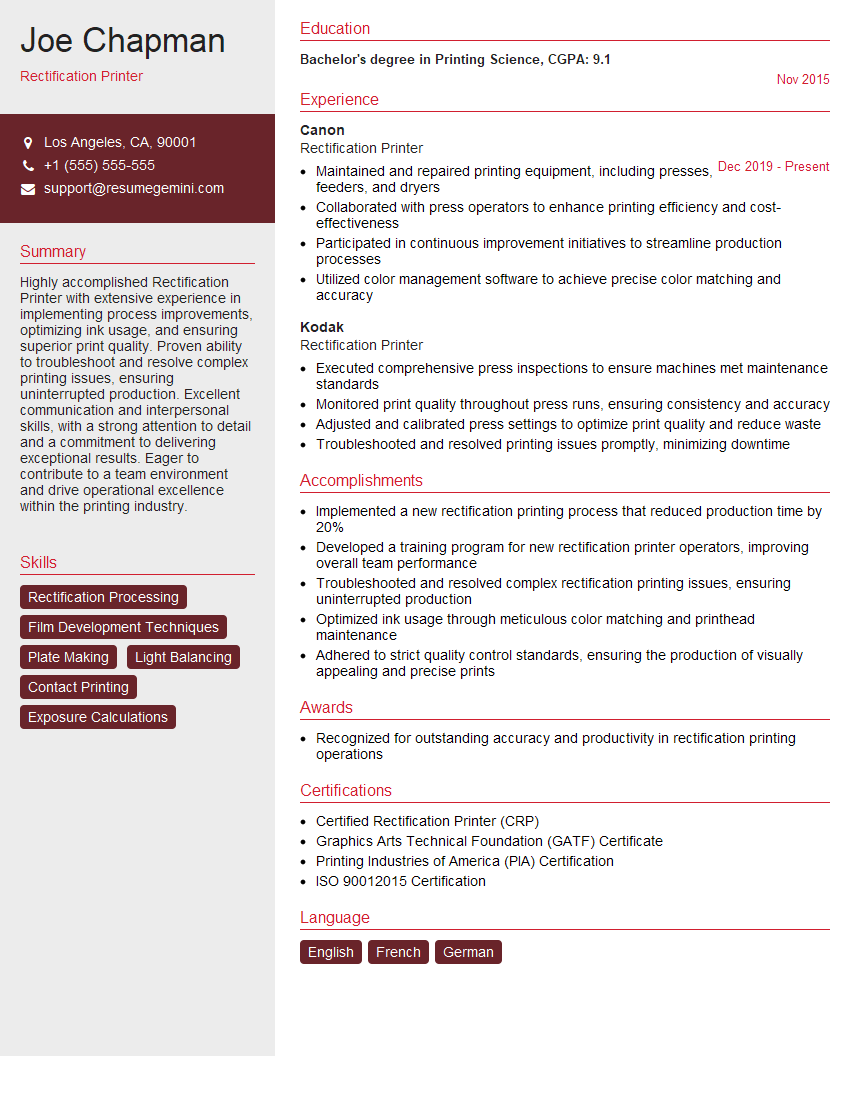

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rectification Printer

1. Explain the process of rectification printing?

Rectification printing is a specialized printing technique that uses a combination of methods to correct and enhance images for optimal printing results. The process typically involves the following steps:

- Image preparation: The image is prepared for printing by adjusting its size, orientation, and color balance.

- Platemaking: The image is transferred to a printing plate, which is used to create the actual print.

- Proofing: A proof is created to verify the accuracy and quality of the print before the final run.

- Printing: The printing process involves transferring ink from the printing plate to the paper or other substrate.

- Finishing: The printed piece may undergo further processing, such as trimming, binding, or coating, to complete the desired result.

2. What are the different types of rectification printing machines?

Digital Rectification Printers

- Use digital technology to create images directly from computer files.

- Offer high resolution and precision, suitable for fine art and photographic printing.

Analog Rectification Printers

- Utilize traditional methods, such as film and chemical processing.

- Provide a wider range of control over the printing process, allowing for artistic adjustments.

Inkjet Rectification Printers

- Employ inkjet technology to deposit ink droplets onto the printing surface.

- Offer versatility in terms of substrates and print sizes.

3. What are the key factors to consider when choosing a rectification printing machine?

When selecting a rectification printing machine, several key factors should be considered:

- Print quality: The resolution, color accuracy, and sharpness of the printed images.

- Speed and efficiency: The rate at which the machine can produce prints.

- Substrate compatibility: The types of materials that the machine can print on.

- Cost: The initial investment and ongoing operating expenses.

- Maintenance and support: The availability and cost of maintenance and technical support.

4. What are the common problems that can occur during rectification printing and how do you troubleshoot them?

Some common problems during rectification printing and their troubleshooting steps include:

- Image distortion: Check for paper alignment and flatness, adjust printer settings, or use different paper.

- Color inaccuracies: Calibrate the printer, check ink levels, or adjust color profiles.

- Streaking or banding: Clean the print heads, adjust ink flow, or replace ink cartridges.

- Paper jams: Clear paper jams, check for obstructions, or adjust paper settings.

- Electrical issues: Check power connections, reset the printer, or contact a technician.

5. What are the latest advancements in rectification printing technology?

Recent advancements in rectification printing technology include:

- Wide-format inkjet printers: Capable of printing large-scale images with high resolution.

- Pigment-based inks: Offer increased durability and lightfastness compared to dye-based inks.

- Artificial intelligence (AI): Used for image enhancement and color correction.

- Cloud-based printing: Allows for remote printing and collaboration.

- Sustainable printing practices: Focus on reducing waste and environmental impact.

6. What are the safety precautions that should be taken when operating a rectification printing machine?

To ensure safety when operating a rectification printing machine, it is crucial to:

- Follow the manufacturer’s instructions carefully.

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Handle chemicals and inks with care, avoiding contact with skin or eyes.

- Maintain a clean and well-ventilated work environment.

- Regularly inspect the machine for any potential hazards.

7. What are the different applications of rectification printing?

Rectification printing has a wide range of applications, including:

- Fine art reproduction: Creating high-quality prints of paintings, drawings, and photographs.

- Commercial printing: Producing brochures, posters, and other marketing materials.

- Technical printing: Creating architectural drawings, maps, and scientific illustrations.

- Industrial printing: Producing labels, packaging, and other industrial products.

- Textile printing: Creating custom designs on fabrics for clothing, home décor, and more.

8. What are the career opportunities available for rectification printers?

Rectification printers can find employment in various industries, including:

- Printing and publishing: Working in commercial printing companies, art studios, or photo labs.

- Fine art: Creating limited edition prints and collaborating with artists.

- Photography: Producing high-quality photographic prints for clients.

- Education: Teaching or assisting in printing courses at universities or workshops.

- Self-employment: Establishing their own printing businesses or freelancing.

9. What are the qualities and skills that make a successful rectification printer?

Successful rectification printers typically possess the following qualities and skills:

- Technical proficiency: Knowledge of printing techniques, equipment, and materials.

- Attention to detail: Ability to produce high-quality prints with accuracy.

- Color management: Understanding of color theory and the ability to match and adjust colors precisely.

- Customer service: Ability to communicate effectively with clients and meet their needs.

- Problem-solving: Ability to troubleshoot and resolve printing issues efficiently.

10. How do you stay up-to-date with the latest advancements in rectification printing technology?

To stay abreast of the latest advancements in rectification printing technology, I actively engage in the following practices:

- Attend industry events and workshops: Participating in conferences and seminars to learn about new techniques and products.

- Read trade publications and online resources: Staying informed through industry-specific magazines, websites, and blogs.

- Connect with industry experts: Networking with other printers, suppliers, and manufacturers to exchange knowledge and ideas.

- Experiment with new techniques and materials: Regularly exploring and testing new technologies to improve my skills and stay competitive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rectification Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rectification Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rectification Printers are responsible for ensuring the quality of printed materials by identifying and correcting errors in the printing process. They work with a variety of printing equipment, including offset, digital, and flexographic presses, and must have a strong understanding of printing techniques and materials.

1. Inspecting printed materials for errors

Rectification Printers carefully inspect printed materials for errors, such as missing or smeared ink, misaligned images, and incorrect colors. They may use a variety of tools to help them with this process, such as magnifying glasses and spectrophotometers.

- Using magnifying glasses to inspect printed materials for errors

- Using spectrophotometers to measure the color of printed materials

2. Identifying the cause of errors

Once a Rectification Printer has identified an error, they must determine the cause of the error. This may involve troubleshooting the printing equipment, inspecting the printing materials, or consulting with other members of the printing team.

- Troubleshooting printing equipment to identify the cause of errors

- Inspecting printing materials to identify the cause of errors

- Consulting with other members of the printing team to identify the cause of errors

3. Correcting errors

Once the cause of an error has been identified, the Rectification Printer must correct the error. This may involve making adjustments to the printing equipment, replacing damaged printing materials, or reprinting the entire job.

- Making adjustments to printing equipment to correct errors

- Replacing damaged printing materials to correct errors

- Reprinting the entire job to correct errors

4. Maintaining printing equipment

Rectification Printers are also responsible for maintaining the printing equipment they use. This may involve cleaning and lubricating the equipment, replacing worn parts, and performing regular maintenance checks.

- Cleaning and lubricating printing equipment

- Replacing worn parts on printing equipment

- Performing regular maintenance checks on printing equipment

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Rectification Printer position:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the job.

- Visit the company’s website to learn about their products or services

- Read articles about the company in industry publications

- Talk to people who work at the company to get their insights

- Review the job description carefully and identify the key skills and experience that the employer is looking for

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, so it’s a good idea to practice your answers ahead of time. This will help you feel more confident and prepared during the interview.

- Tell me about yourself ( Example: I am a highly experienced Rectification Printer with over 10 years of experience in the printing industry. I have a strong understanding of printing techniques and materials, and I am proficient in identifying and correcting errors in the printing process. I am also skilled in maintaining printing equipment and performing regular maintenance checks.)

- Why are you interested in this position (Example: I am interested in this position because I am passionate about printing and I am confident that I have the skills and experience to be successful in this role. I am also eager to learn new things and I am excited about the opportunity to work with a team of experienced professionals.)

- What are your strengths (Example: My strengths include my attention to detail, my problem-solving skills, and my ability to work independently. I am also a team player and I am always willing to help out my colleagues.)

- What are your weaknesses (Example: One of my weaknesses is that I can be a bit of a perfectionist. I sometimes spend too much time trying to get things just right, which can slow me down. I am working on overcoming this weakness by setting realistic deadlines for myself and by delegating tasks to others when necessary.)

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, as being late can be seen as disrespectful.

- Choose clothing that is clean, pressed, and fits well

- Avoid wearing clothing that is too revealing or too casual

- Plan your route to the interview in advance so that you can arrive on time

4. Be yourself and be honest

The most important thing is to be yourself and be honest during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and be honest about your experience and skills.

- Don’t try to be someone you’re not

- Be confident in your abilities

- Be honest about your experience and skills

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rectification Printer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!