Are you gearing up for an interview for a Box Sealing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Box Sealing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

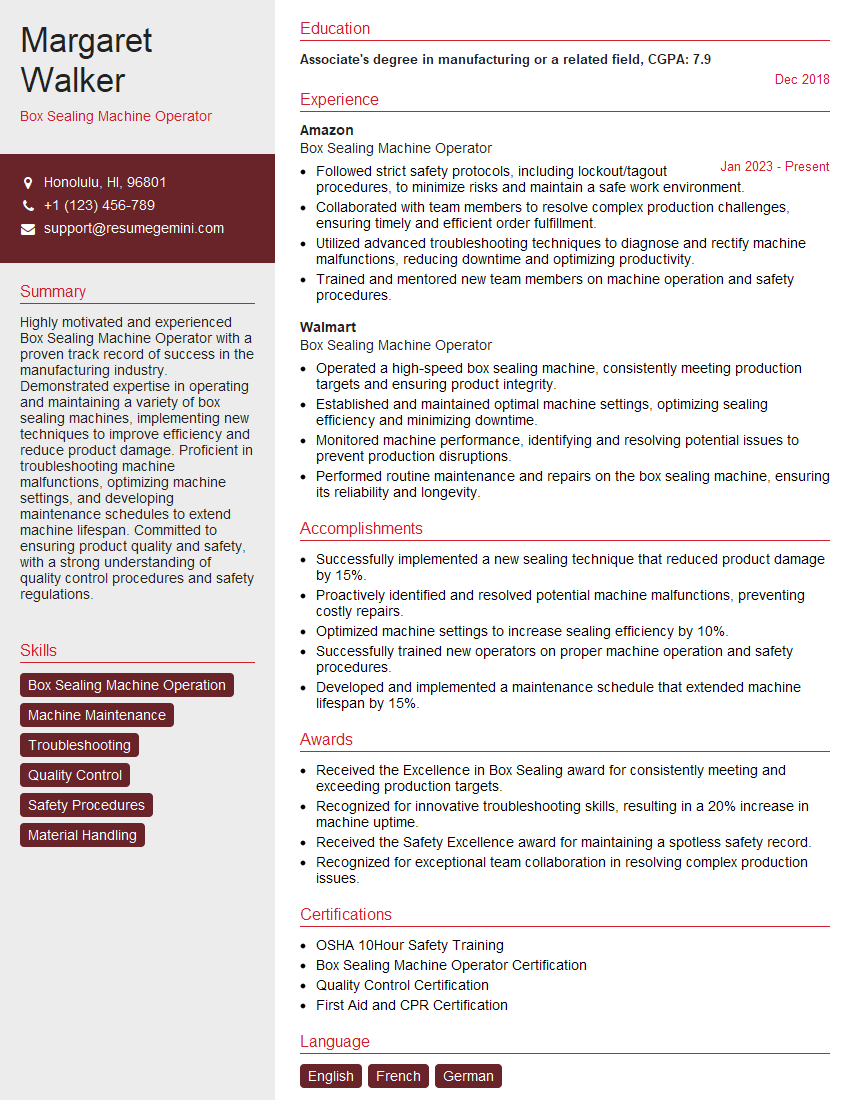

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Sealing Machine Operator

1. Describe the different types of box sealing machines and their applications?

There are various types of box sealing machines, each designed for specific applications. Here are some common types:

- Top and Bottom Sealing Machines: These machines seal the top and bottom flaps of a box simultaneously using adhesive tape or glue.

- Side Sealing Machines: Designed to seal the side flaps of a box, they can use pressure-sensitive tape, glue, or heat sealing.

- Random Case Sealers: These versatile machines can seal boxes of various sizes and shapes, accommodating different dimensions and flap arrangements.

- Inline Case Sealers: Integrated into production lines, these machines automate the sealing process, increasing efficiency.

- Semi-Automatic Case Sealers: Require manual box loading and unloading, but offer a cost-effective solution for low-volume applications.

2. Explain the key maintenance tasks required for box sealing machines?

Preventive Maintenance:

- Regularly inspect and clean all machine components, including the sealing head, conveyor belts, and sensors.

- Lubricate moving parts as per the manufacturer’s guidelines.

- Check and adjust tension in conveyor belts to ensure proper box handling.

Corrective Maintenance:

- Troubleshooting and repairing sealing head issues, such as clogged nozzles or malfunctioning sensors.

- Replacing worn or damaged conveyor belts.

- Recalibrating sensors to maintain accurate sealing.

3. How do you ensure the proper alignment of boxes during the sealing process?

Proper box alignment is crucial for efficient and effective sealing. Here are some techniques to ensure alignment:

- Use alignment guides or adjustable fences to position boxes correctly on the conveyor.

- Calibrate the sealing head and conveyor system to ensure precision.

- Employ vision systems or sensors to detect box position and make necessary adjustments.

4. Describe the different types of sealing tapes used in box sealing machines and their advantages?

- Pressure-Sensitive Tape: Easy to apply, adheres without heat or moisture, suitable for a wide range of surfaces.

- Hot Melt Glue: Provides a strong bond, can handle heavy loads, but requires special applicators.

- Water-Activated Tape: Forms a strong bond when moistened, tamper-evident, ideal for high-security applications.

- Staples: Used in cardboard box sealing machines, provides a secure closure but may damage the box.

5. How do you handle and troubleshoot common problems encountered in box sealing machines?

- Poor Sealing Quality: Check tape tension, nozzle alignment, and sensor calibration.

- Box Misalignment: Adjust alignment guides, recalibrate sensors, or use vision systems.

- Machine Jams: Clear debris, inspect conveyor belts, and check for sensor malfunctions.

- Electrical Faults: Inspect wiring, fuses, and electrical components.

- Leaking Glue: Tighten connections, replace worn seals, or adjust glue viscosity.

6. How do you ensure the safety of operators working with box sealing machines?

Operator safety is paramount. Here are some essential precautions:

- Provide adequate training on machine operation and safety procedures.

- Install safety guards and emergency stop buttons.

- Enforce the use of personal protective equipment (PPE).

- Regularly inspect and maintain the machine to prevent malfunctions.

- Establish clear communication protocols to minimize operator errors.

7. How do you optimize the efficiency of box sealing operations?

- Streamline the workflow and minimize box handling.

- Automate processes using conveyors and inline systems.

- Regularly monitor machine performance and make necessary adjustments.

- Train operators on proper loading and unloading techniques.

- Use high-quality sealing materials and equipment to minimize downtime.

8. What are the latest technological advancements in box sealing machines?

- Automatic Box Size Detection: Machines use vision systems to adjust sealing positions automatically.

- Smart Sensors: Monitor temperature, pressure, and other parameters to optimize sealing quality.

- Remote Monitoring: Allows real-time monitoring and control of machines from remote locations.

- AI-Powered Optimization: Algorithms analyze data to identify and rectify inefficiencies.

9. How do you manage multiple box sealing machines simultaneously?

Managing multiple machines requires effective coordination and monitoring.

- Establish a clear schedule and workflow to avoid conflicts.

- Use a centralized control system for real-time monitoring of all machines.

- Prioritize tasks based on urgency and importance.

- Delegate responsibilities to ensure timely task completion.

- Communicate with operators regularly to address any issues promptly.

10. Describe your experience in implementing lean manufacturing principles to improve box sealing operations?

- Waste Reduction: Identified and eliminated unnecessary steps in the sealing process.

- Flow Improvement: Streamlined box handling and optimized machine utilization.

- Standardization: Established consistent operating procedures and work instructions.

- Continuous Improvement: Regularly monitored and made adjustments to enhance efficiency.

- Collaboration: Involved operators and supervisors in the improvement process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Sealing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Sealing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Box Sealing Machine Operator is responsible for operating and maintaining a box sealing machine in a manufacturing or packaging environment. Key responsibilities include:

1. Machine Operation

Setting up, operating, and monitoring the box sealing machine.

- Loading boxes into the machine.

- Adjusting machine settings to ensure proper sealing.

2. Quality Control

Inspecting boxes to ensure proper sealing and quality.

- Identifying and correcting any sealing defects.

- Maintaining records of quality checks.

3. Machine Maintenance

Performing routine maintenance and minor repairs on the sealing machine.

- Cleaning and lubricating machine components.

- Identifying and reporting any major maintenance issues.

4. Safety

Following all safety procedures and regulations.

- Wearing appropriate safety gear.

- Operating the machine in a safe manner.

Interview Tips

To ace the interview for a Box Sealing Machine Operator position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry. Research the specific responsibilities of the Box Sealing Machine Operator role and identify how your skills and experience align.

- Review the company’s website, social media profiles, and industry news.

- Read the job description thoroughly and highlight your relevant qualifications.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating box sealing machines. Mention any experience with different types of machines and your ability to adjust settings and troubleshoot problems.

- Provide specific examples of your machine operation skills.

- Quantify your results, such as the number of boxes sealed per hour or the reduction in sealing defects achieved.

3. Demonstrate Your Quality Control Experience

Showcase your attention to detail and commitment to quality. Explain your process for inspecting boxes and identifying defects. Mention any quality control techniques or certifications you have obtained.

- Describe your methods for inspecting boxes for proper sealing, dimensions, and appearance.

- Share examples of how you handled defective boxes and ensured product quality.

4. Emphasize Your Safety Awareness

Highlight your understanding of safety procedures and regulations related to operating box sealing machines. Explain how you maintain a safe work environment and follow all safety protocols.

- Describe your knowledge of safety equipment and proper usage.

- Provide examples of how you have identified and addressed potential safety hazards.

5. Be Enthusiastic and Willing to Learn

Convey your enthusiasm for operating box sealing machines and your eagerness to learn more about the industry. Express your willingness to follow instructions, receive feedback, and improve your skills.

- Explain why you are interested in the role and what motivates you.

- Ask thoughtful questions about the company, the role, and the industry to show your engagement and curiosity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Box Sealing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.