Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Core Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

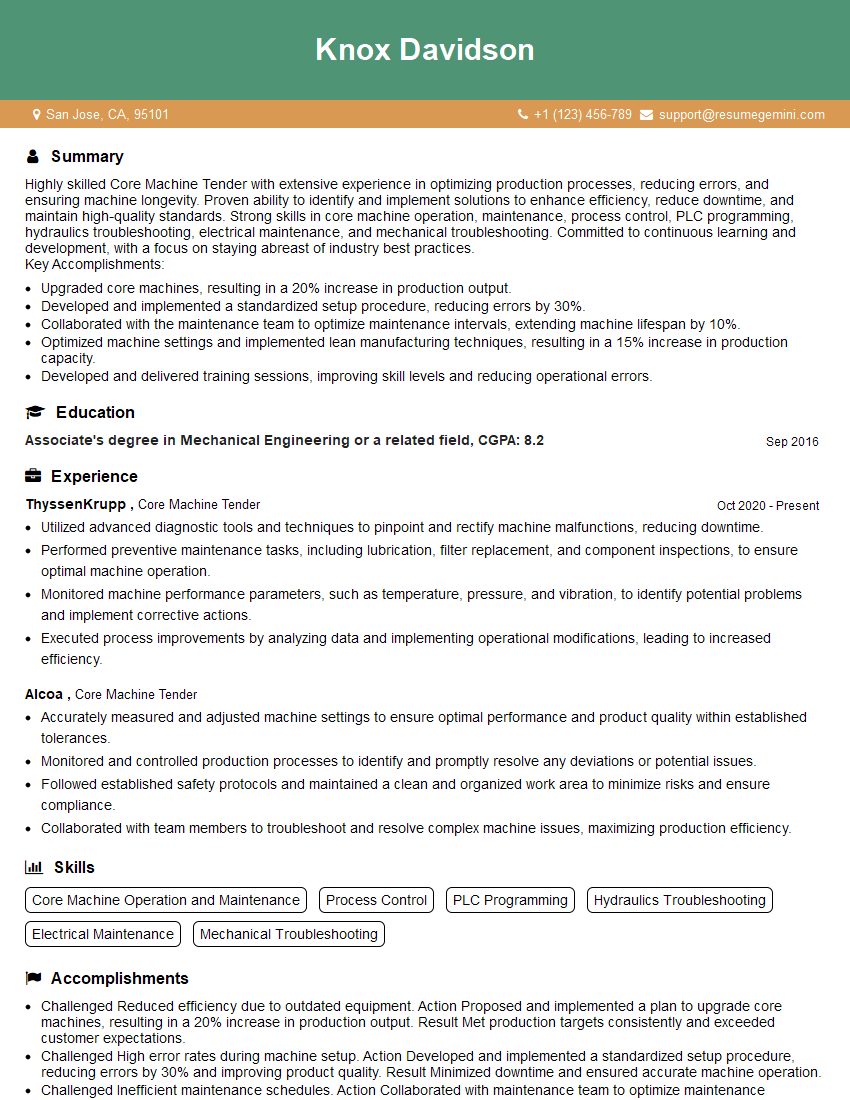

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Machine Tender

1. What are the key responsibilities of a Core Machine Tender?

- Operate and maintain the core machines, including the core maker, core blower, and sand mixer.

- Inspect cores for defects and repair or replace them as necessary.

- Monitor the core making process and make adjustments to ensure that cores are produced to the required specifications.

- Keep the core room clean and organized, and ensure that all safety regulations are followed.

2. What are the different types of core making processes?

Cold Box Process

- Uses a chemical binder that hardens at room temperature.

- Suitable for cores that require high strength and precision.

Hot Box Process

- Uses a binder that is activated by heat.

- Produces cores with good strength and dimensional accuracy.

Green Sand Process

- Uses a mixture of sand, clay, and water to form the core.

- Simple and inexpensive process, but cores have lower strength and accuracy.

3. What are the common defects that can occur in cores?

- Blowholes: Holes in the core caused by trapped air or gas.

- Cracks: Fractures in the core caused by shrinkage or stress.

- Scabs: Surface defects caused by the detachment of sand grains.

- Flash: Excess material that forms around the edges of the core.

4. How do you inspect cores for defects?

- Visually inspect the core for any cracks, holes, or other surface defects.

- Use a core gauge to check the dimensions of the core and ensure that it meets the required specifications.

- Perform a core blow test to check the strength of the core and its ability to withstand internal pressure.

5. How do you repair or replace defective cores?

The method of repair or replacement depends on the type of defect and the severity of the damage.

- Minor defects, such as blowholes or scabs, can be repaired using a patching compound.

- Cracks can be repaired by welding or brazing.

- Severely damaged cores may need to be replaced.

6. What are the safety precautions that must be followed when working in a core room?

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

- Be aware of the location of emergency exits and fire extinguishers.

- Do not operate machines without proper training and authorization.

- Keep the core room clean and organized to prevent tripping hazards.

7. What is the importance of maintaining the core machines properly?

- Proper maintenance ensures that the machines operate efficiently and produce consistent, high-quality cores.

- Regular maintenance helps to extend the life of the machines and reduce the risk of breakdowns.

- A well-maintained core room is a safer and more productive work environment.

8. What are the different types of sand that can be used in core making?

- Silica sand: The most common type of sand used in core making.

- Zircon sand: A high-quality sand that produces cores with excellent strength and thermal resistance.

- Olivine sand: A lightweight sand that is used to make cores for large castings.

9. How do you determine the correct sand mix for a particular core?

The correct sand mix depends on the type of core being made, the size and weight of the casting, and the casting process being used.

- Factors to consider include the sand grain size, the binder type and amount, and the moisture content.

- Core makers typically use a trial-and-error approach to determine the optimal sand mix.

10. What are the different types of core dryers?

- Tower dryers: Use a heated air stream to dry cores.

- Batch ovens: Dry cores in a heated chamber.

- Microwave dryers: Use microwaves to heat and dry cores.

- Infrared dryers: Use infrared radiation to heat and dry cores.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Core Machine Tender is a crucial role within a manufacturing or production environment, primarily responsible for the efficient and effective operation, maintenance, and troubleshooting of core-making machinery.

1. Machine Operation and Monitoring

The Core Machine Tender is entrusted with the seamless operation of core-making machines, ensuring they perform to optimal standards. They meticulously monitor machine functions, identify potential issues, and make prompt adjustments as needed.

- Starts up, operates, and shuts down core-making machines following established procedures.

- Monitors machine performance, including temperature, pressure, and cycle times, to detect and address any anomalies.

2. Material Handling and Management

The Core Machine Tender is responsible for managing various materials used in the core-making process, ensuring an uninterrupted supply and minimizing waste.

- Loads and unloads raw materials, such as sand, resins, and binders, into the machines.

- Maintains a clean and organized work area, adhering to safety regulations and environmental standards.

3. Maintenance and Troubleshooting

The Core Machine Tender plays a pivotal role in maintaining the integrity and efficiency of core-making equipment. They conduct regular inspections, identify issues, and perform necessary repairs or adjustments.

- Performs routine maintenance tasks, including lubrication, cleaning, and basic repairs.

- Troubleshoots machine malfunctions, identifying root causes and implementing appropriate solutions.

4. Quality Control

The Core Machine Tender is responsible for monitoring the quality of cores produced by the machines. They ensure that cores meet the required specifications and contribute to the overall quality of the final product.

- Inspects cores for defects, such as cracks, voids, and dimensional deviations.

- Maintains records and reports on machine performance, including downtime and quality metrics.

Interview Tips

To ace an interview for the Core Machine Tender position, candidates should meticulously prepare and showcase their relevant skills and experience. Here are some valuable tips:

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific Core Machine Tender role. This will demonstrate your interest and enthusiasm for the position and allow you to ask informed questions.

- Visit the company’s website and social media pages to gain insights into their culture, values, and products/services.

- Study the job description and identify the key responsibilities, skills, and qualifications required.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your relevant experience and skills that align with the job requirements. Provide specific examples of your accomplishments and how they have contributed to the success of your previous roles.

- Discuss your experience in operating and maintaining core-making machines, troubleshooting issues, and ensuring quality production.

- Highlight your knowledge of industry-specific standards, safety protocols, and quality control procedures.

3. Demonstrate Problem-Solving and Analytical Abilities

Core Machine Tenders are often required to solve unexpected problems and make quick decisions. In the interview, demonstrate your problem-solving and analytical skills by providing examples of how you have successfully handled challenges in previous roles.

- Describe a situation where you identified and resolved a machine malfunction, minimizing downtime and maintaining production efficiency.

- Discuss how you analyze data and trends to identify potential issues and implement preventive measures.

4. Prepare Questions for the Interviewer

Asking well-thought-out questions at the end of the interview shows that you are engaged, interested, and keen to learn more. Prepare a few intelligent questions that demonstrate your curiosity and desire to contribute to the company’s goals.

- Inquire about the company’s current projects and future plans within the industry.

- Ask about the specific challenges and opportunities associated with the Core Machine Tender role in the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!