Feeling lost in a sea of interview questions? Landed that dream interview for Glue Reel Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Glue Reel Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

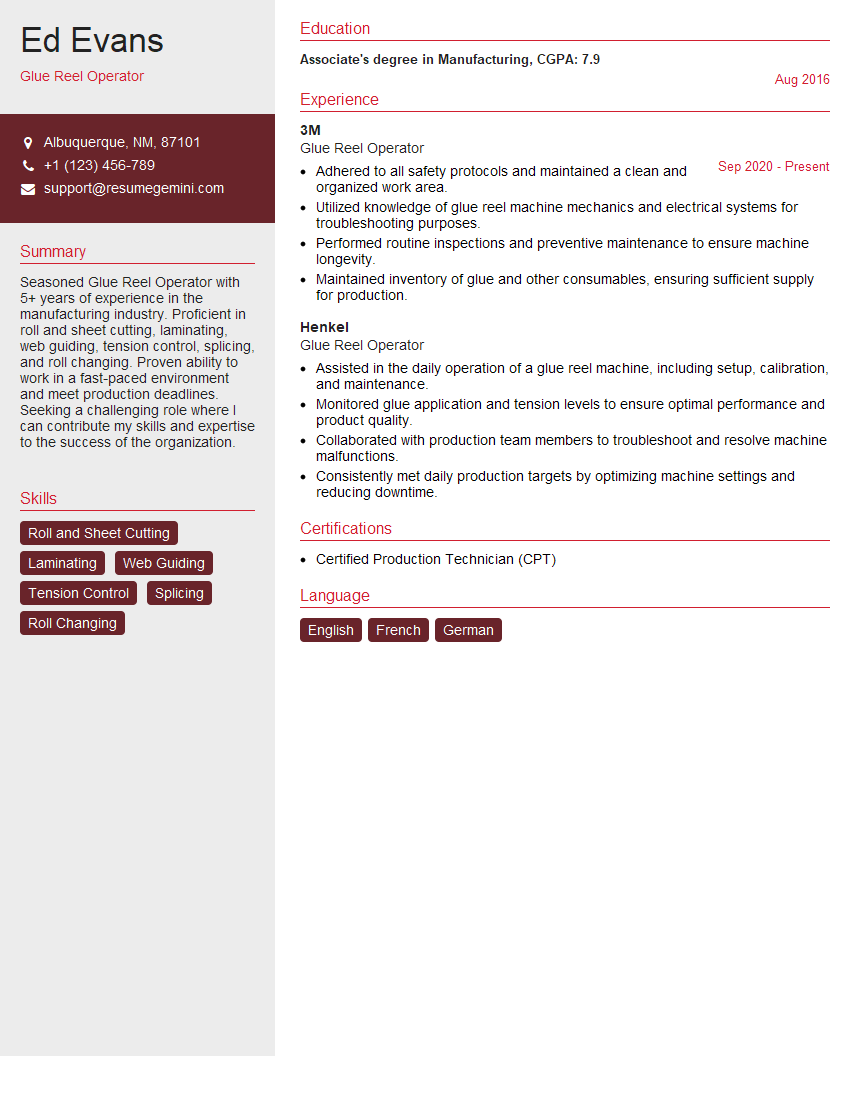

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Reel Operator

1. Describe your experience in operating a glue reel machine?

In my previous role at [Company Name], I operated a glue reel machine for over 5 years. My responsibilities included:

- Loading and unloading glue reels

- Monitoring glue levels and adjusting as needed

- Maintaining and troubleshooting the glue reel machine

- Ensuring glue quality and consistency

2. What are the different types of glue used in glue reel machines?

Solvent-Based Glue

- Strong and fast-drying

- Suitable for bonding a variety of materials, including wood, metal, and plastic

- Requires special handling and ventilation

Water-Based Glue

- Easy to use and clean up

- Non-toxic and low-odor

- Dries slower than solvent-based glue

Hot Melt Glue

- Bonds instantly upon contact

- Useful for high-volume applications

- Requires special equipment for application

3. How do you ensure the quality of the glue application?

I follow these steps to ensure the quality of the glue application:

- Inspecting the glue reel for any damage or defects

- Monitoring the glue level and adjusting as needed

- Calibrating the glue reel machine according to the manufacturer’s instructions

- Testing the glue application on a scrap material before applying it to the final product

- Inspecting the final product for any glue defects

4. How do you troubleshoot common problems with glue reel machines?

I have experience troubleshooting various problems with glue reel machines, including:

- Glue leaks

- Uneven glue application

- Clogged glue nozzles

- Overheating

- Electrical problems

I follow a systematic approach to troubleshooting, which involves identifying the problem, determining the cause, and implementing the appropriate solution.

5. What are the safety precautions that you observe when operating a glue reel machine?

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and hearing protection

- Ensuring the machine is properly grounded

- Handling glue chemicals with care

- Keeping the work area clean and free of obstructions

- Following all manufacturer’s instructions and safety protocols

6. How do you maintain and clean a glue reel machine?

I perform regular maintenance and cleaning tasks to ensure the glue reel machine operates efficiently and safely, including:

- Cleaning the glue reel and glue nozzles

- Lubricating moving parts

- Checking and adjusting the tension of the glue reel

- Inspecting electrical components and connections

- Following the manufacturer’s recommended maintenance schedule

7. What are the different types of materials that can be glued using a glue reel machine?

A glue reel machine can be used to glue a wide range of materials, including:

- Paper and cardboard

- Wood and wood products

- Metal and plastic

- Fabric and leather

- Glass and ceramics

The specific type of glue used will depend on the materials being bonded.

8. How do you handle and store glue safely?

I handle and store glue safely by:

- Wearing appropriate personal protective equipment, such as gloves and safety glasses

- Storing glue in a cool, dry, and well-ventilated area

- Keeping glue containers tightly sealed when not in use

- Following the manufacturer’s instructions for storage and handling

- Disposing of glue properly according to local regulations

9. What is the importance of maintaining accurate records when operating a glue reel machine?

Maintaining accurate records is important for several reasons:

- Tracking glue usage and inventory

- Documenting maintenance and repairs

- Ensuring quality control

- Complying with industry regulations

- Providing evidence in case of accidents or disputes

10. How do you stay up-to-date with the latest advancements in glue reel technology?

I stay up-to-date with the latest advancements in glue reel technology by:

- Reading industry publications and attending trade shows

- Participating in online forums and discussions

- Consulting with equipment manufacturers and suppliers

- Seeking training and certification opportunities

- Experimenting with different glue types and application methods

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Reel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Reel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Glue Reel Operator plays a crucial role in the production process, ensuring the efficient and smooth operation of the glue reel machine. Their primary responsibilities include:

1. Reel Operation and Maintenance

Operate the glue reel machine, ensuring its smooth operation and optimal performance.

- Monitor machine settings and make necessary adjustments to maintain production quality.

- Inspect and maintain machine components, including rollers, belts, and gears, to prevent downtime.

2. Glue Application and Control

Apply adhesive to the specified substrates, achieving consistent and accurate gluing.

- Adjust glue application parameters, such as flow rate, spread width, and pressure, to meet production requirements.

- Monitor glue viscosity and make adjustments to ensure proper bonding and adhesion.

3. Substrate Handling and Inspection

Handle substrates with care to prevent damage or contamination.

- Inspect substrates for defects or imperfections that may affect gluing quality.

- Ensure proper alignment and positioning of substrates on the glue reel machine.

4. Quality Control and Process Monitoring

Monitor the gluing process and ensure the production of high-quality products.

- Inspect glued substrates for defects, ensuring they meet established quality standards.

- Track production data and report any irregularities or deviations from standard operating procedures.

Interview Tips

To ace the interview for a Glue Reel Operator position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some key interview tips:

1. Research the Company and Role

Research the company’s history, products or services, and the specific responsibilities of the Glue Reel Operator role. This will help you understand the company’s needs and tailor your answers accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating glue reel machines and handling substrates with care. Showcase your understanding of glue application and control parameters, as well as your attention to detail and quality.

3. Prepare for Technical Questions

Anticipate technical questions about the glue reel machine and its operation. Be prepared to discuss your knowledge of machine components, troubleshooting techniques, and quality control procedures.

4. Practice Behavioral Interview Questions

Prepare for behavioral interview questions that assess your work ethic, problem-solving skills, and teamwork abilities. Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

5. Dress Professionally and Show Enthusiasm

Dress appropriately for the interview and maintain a professional and enthusiastic demeanor. Express your interest in the role and demonstrate your commitment to delivering high-quality work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glue Reel Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!