Feeling lost in a sea of interview questions? Landed that dream interview for Glue Line Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Glue Line Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

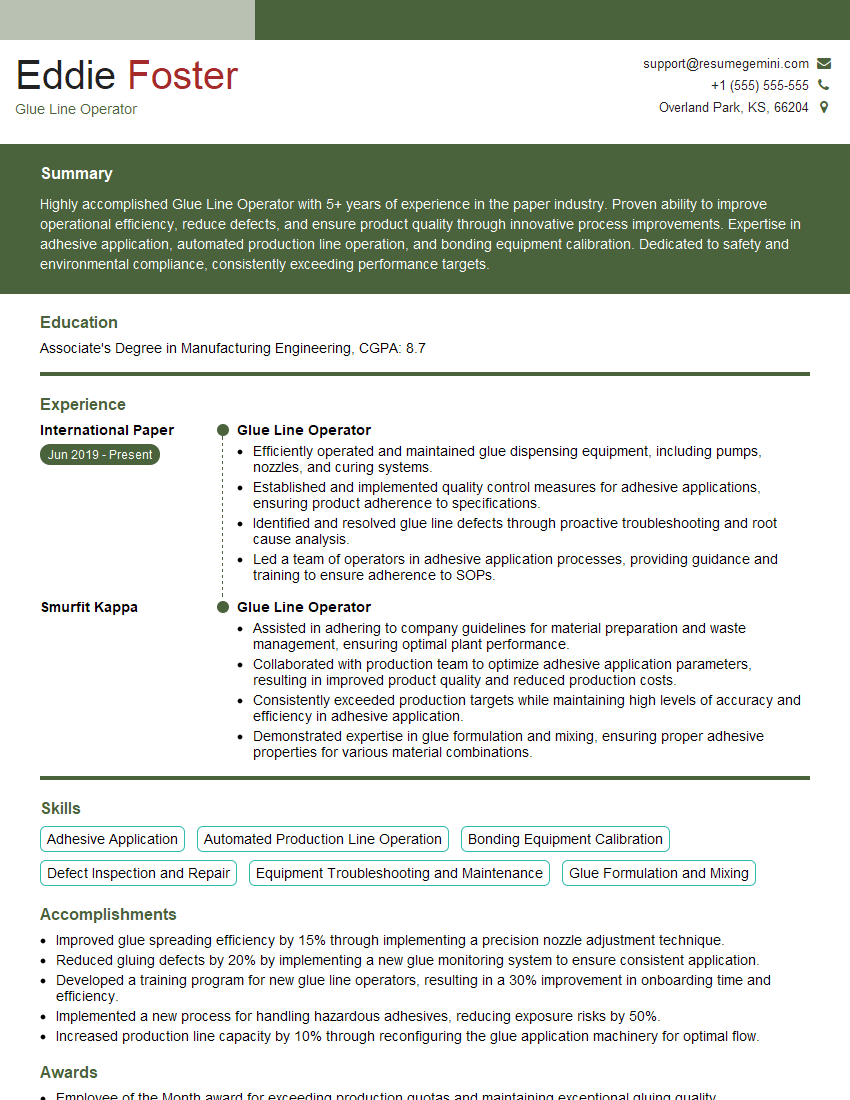

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Line Operator

1. Explain the role and responsibilities of a Glue Line Operator?

As a Glue Line Operator, I am responsible for operating and monitoring a glue line machine to ensure the proper assembly of products. My duties include loading and unloading materials, setting up and adjusting machine parameters, and inspecting products to ensure quality. I am also responsible for maintaining the machine, performing routine maintenance tasks, and identifying and resolving any issues that may arise.

2. What types of glue application methods are there?

Hot melt glue application

- Used for bonding a wide range of materials, including paper, plastic, wood, and metal.

- Benefits: fast setting time, strong bond strength

Solvent-based glue application

- Used for bonding porous materials, such as paper, cardboard, and fabric.

- Benefits: good adhesion to rough surfaces, provides a strong and flexible bond

Water-based glue application

- Used for bonding a variety of materials, including paper, wood, and fabric.

- Benefits: easy to clean up, environmentally friendly

3. What factors affect the strength of a glued bond?

The strength of a glued bond depends on several factors, including:

- Type of glue used

- Surface preparation of the materials being bonded

- Amount of glue applied

- Bonding pressure and time

- Environmental conditions

4. How do you ensure the quality of glued products?

I ensure the quality of glued products by:

- Inspecting materials before gluing to identify any defects.

- Following established gluing procedures and specifications.

- Using appropriate equipment and tools.

- Performing regular quality checks during the gluing process.

- Documenting all quality control activities.

5. What are some common problems that can occur during gluing and how do you resolve them?

Some common problems that can occur during gluing include:

- Weak bond strength: can be caused by insufficient glue application, improper surface preparation, or using the wrong type of glue.

- Glue bleed-through: occurs when too much glue is applied and it seeps through the materials being bonded.

- Warped or distorted materials: can be caused by uneven glue application or excessive bonding pressure.

To resolve these problems, I would:

- Adjust the amount of glue applied.

- Ensure that the materials are properly prepared before gluing.

- Use the correct type of glue for the materials being bonded.

- Apply the glue evenly and use the recommended bonding pressure and time.

6. How do you maintain and calibrate a glue line machine?

To maintain and calibrate a glue line machine, I would:

- Regularly clean and lubricate the machine.

- Inspect the glue application system for any wear or damage.

- Check the machine’s settings and adjust them as needed.

- Calibrate the machine using a certified reference material.

7. What safety precautions should be taken when working on a glue line machine?

When working on a glue line machine, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Keep hands away from moving parts.

- Do not operate the machine if it is not properly grounded.

- Be aware of the location of fire extinguishers and other emergency equipment.

- Follow all established safety procedures.

8. What are some recent advancements in glue line technology?

Some recent advancements in glue line technology include:

- Automated glue application systems: These systems use robots or other automated equipment to apply glue to products, improving accuracy and efficiency.

- Laser-guided glue application: This technology uses lasers to guide the glue application process, ensuring precise and consistent glue placement.

- UV-curable glues: These glues cure when exposed to ultraviolet light, providing faster bonding times and improved adhesion.

9. How do you stay up-to-date with the latest trends and developments in the glue line industry?

I stay up-to-date with the latest trends and developments in the glue line industry by:

- Reading industry publications and attending trade shows.

- Networking with other professionals in the field.

- Participating in training and development programs.

10. How do you troubleshoot problems with a glue line machine?

To troubleshoot problems with a glue line machine, I would:

- Identify the symptoms of the problem.

- Check the machine’s settings and adjust them as needed.

- Inspect the glue application system for any wear or damage.

- Clean and lubricate the machine.

- Consult the machine’s manual or contact the manufacturer for assistance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Line Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Line Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glue Line Operator plays a crucial role in the adhesive bonding process, ensuring the proper application of glue to various materials. Their primary responsibilities encompass:

1. Glue Application

Utilizing specialized equipment, they apply glue precisely to designated surfaces based on established specifications.

- Calibrating and maintaining gluing equipment, ensuring optimal performance.

- Monitoring glue levels and replenishing as needed to maintain production flow.

2. Material Handling

Efficiently handling materials throughout the gluing process, adhering to safety protocols.

- Loading and unloading materials onto the gluing line.

- Positioning materials accurately for precise glue application.

3. Quality Control

Inspecting glued materials thoroughly to verify adherence to quality standards.

- Identifying and addressing defects or inconsistencies in the gluing process.

- Maintaining detailed records of quality checks and reporting any issues promptly.

4. Machine Maintenance

Performing basic maintenance and cleaning tasks on gluing equipment to ensure smooth operation.

- Cleaning and lubricating equipment components.

- Identifying potential maintenance issues and reporting them for timely resolution.

Interview Tips

To ace the interview for a Glue Line Operator position, consider the following tips and hacks:

1. Research the Company and Role

Demonstrate your interest and enthusiasm by researching the company’s industry, products, and specific requirements for the role. Understanding the company’s values and mission will help you align your qualifications and experience with their needs.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in glue application techniques, material handling procedures, and quality control measures. If you have experience working with specific types of glue or materials, be sure to mention it. Quantify your accomplishments whenever possible, using specific numbers and metrics to showcase your impact.

3. Demonstrate Attention to Detail

As a Glue Line Operator, meticulous attention to detail is paramount. During the interview, provide examples of your ability to identify and rectify errors or inconsistencies in your work. Explain how you ensure accuracy and precision in your tasks.

4. Prepare for Technical Questions

Anticipate technical questions related to glue application, equipment operation, and quality control. Familiarize yourself with common gluing methods, adhesive properties, and quality inspection techniques. Be prepared to discuss your understanding of these concepts and how you apply them in your work.

5. Show Eagerness to Learn and Grow

Express your willingness to learn new skills and take on additional responsibilities. Demonstrate a positive attitude towards continuous improvement and a commitment to maintaining a safe and efficient work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Glue Line Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.