Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Liner Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

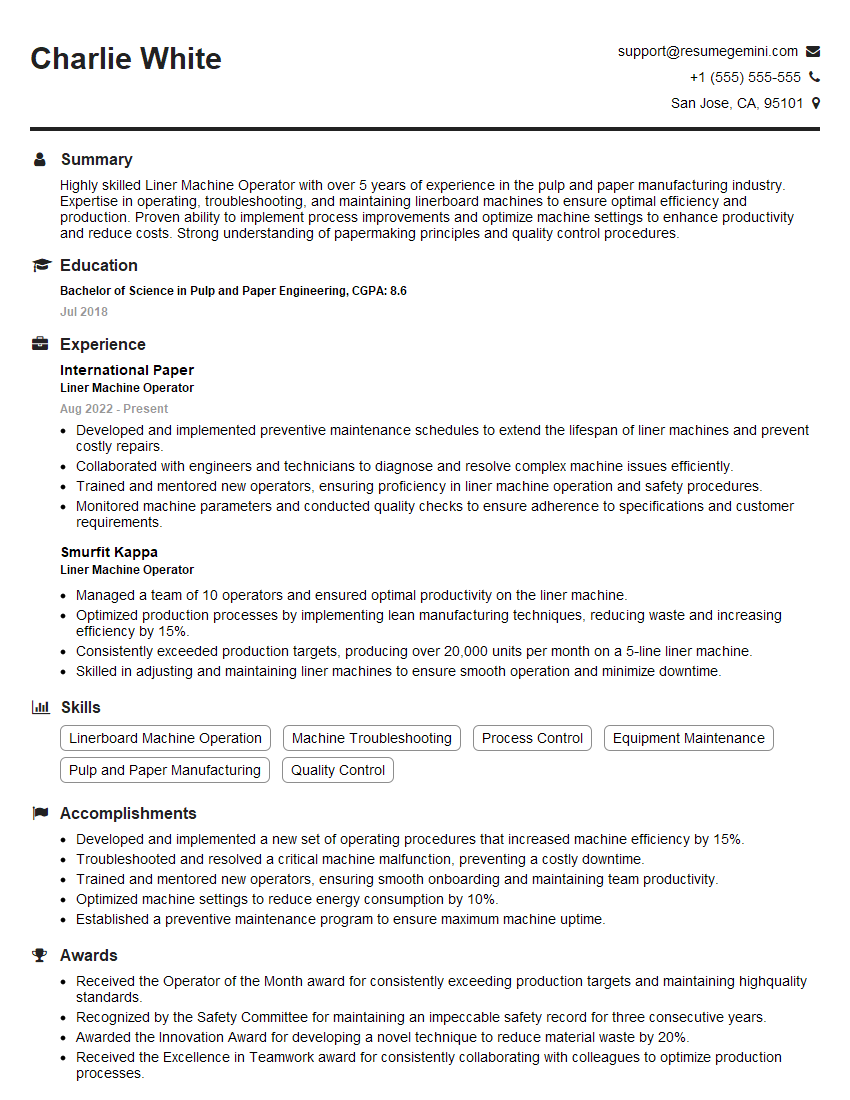

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liner Machine Operator

1. How would you describe the importance of proper tension settings in liner operation?

Proper tension settings are crucial in liner operation for several reasons:

- Product Quality: Optimal tension ensures the liner is taut and free of wrinkles, resulting in a clean and precise fold.

- Machine Performance: Correct tension prevents slippage and ensures smooth operation, reducing wear and tear on the machine.

- Safety: Excessive tension can cause the liner to snap or tear, posing a potential safety hazard.

2. Explain the process of setting up a liner machine for a new material.

Material Preparation

- Verify the material specifications and determine the appropriate liner type.

- Condition the material if necessary to ensure consistent folding.

Machine Adjustments

- Set the feed rollers to the correct gap to accommodate the material thickness.

- Adjust the tension settings to suit the material type and desired fold quality.

- Fine-tune the folding mechanism to achieve the desired fold angle and sharpness.

3. How do you troubleshoot liner breaks and misfolds?

Troubleshooting liner breaks and misfolds involves:

- Liner Breaks: Check tension settings, material condition, and machine alignment. Ensure there are no sharp edges or imperfections in the material.

- Misfolds: Inspect the folding mechanism for wear or misalignment. Adjust tension settings, and verify the feed rollers are properly calibrated.

4. What factors affect the speed and quality of lining operations?

Factors affecting speed and quality include:

- Machine Efficiency: Regular maintenance and proper adjustments ensure optimal machine performance.

- Material Properties: The thickness, type, and condition of the material impact folding speed and quality.

- Operator Skill: Skilled operators can adjust settings and troubleshoot issues quickly, maximizing output.

5. Describe the safety precautions you follow when operating a liner machine.

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of tripping hazards.

- Be aware of moving parts and avoid loose clothing that could get caught.

- Follow lockout/tagout procedures when servicing or repairing the machine.

- Report any safety concerns or malfunctions to a supervisor immediately.

6. Explain how you maintain and calibrate a liner machine for optimal performance.

Maintenance and calibration include:

- Regular Cleaning: Remove dust, debris, and adhesive buildup to prevent jams and ensure smooth operation.

- Lubrication: Apply lubricants to moving parts according to manufacturer specifications.

- Calibration: Check and adjust tension settings, folding mechanisms, and feed rollers to ensure precision and accuracy.

7. What are the common challenges you have faced as a Liner Machine Operator and how have you overcome them?

Common challenges and solutions:

- Material Variations: Adjust tension settings, feed speeds, and folding mechanisms to accommodate different materials.

- Equipment Malfunctions: Troubleshoot and resolve machine issues promptly to minimize downtime.

- Production Deadlines: Prioritize tasks, optimize machine settings, and work efficiently to meet deadlines.

8. How do you stay up-to-date with the latest advancements in liner production technology?

- Attend industry events and webinars.

- Read technical literature and periodicals.

- Network with fellow operators and industry professionals.

9. Describe how you have contributed to improving the efficiency or safety of lining operations in your previous role.

Contributions may include:

- Implementing new folding techniques or process improvements.

- Identifying and resolving safety hazards.

- Training new operators or sharing best practices.

10. Why are you interested in working as a Liner Machine Operator for our organization?

Reasons for interest may include:

- Company reputation and commitment to innovation.

- Opportunities for professional growth and development.

- Alignment of personal values with the company culture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liner Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liner Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Liner Machine Operator:

1. Machine Operation:

The primary responsibility of a Liner Machine Operator is to proficiently operate liner machines, ensuring smooth production of paperboard or cardboard liners.

- Start, monitor, and control liner machine operations, including speed adjustment, web tension control, and moisture management.

- Troubleshoot and resolve any machine malfunctions promptly to minimize downtime and maintain production efficiency.

2. Production Monitoring:

Monitor and track production quality, ensuring liners meet specifications and customer requirements.

- Conduct regular quality checks using testing equipment, such as basis weight scales, moisture gauges, and caliper testers.

- Identify and rectify any deviations from specifications to maintain optimal product quality.

3. Material Handling:

Handle and load raw materials, such as pulp and chemicals, into the liner machine efficiently and safely.

- Operate forklifts or cranes to transport materials to and from the machine.

- Ensure proper storage and handling of materials to prevent contamination or damage.

4. Maintenance and Cleaning:

Perform routine maintenance and cleaning tasks to maintain the liner machine and related equipment in optimal condition.

- Lubricate and clean machine components to minimize wear and tear.

- Inspect conveyor belts, bearings, and hydraulic systems for potential issues.

5. Quality Control:

Collaborate with quality control personnel to identify and resolve any quality issues with the liners.

- Maintain detailed records of production parameters and quality control tests.

- Implement corrective actions to address any quality concerns and prevent recurrence.

6. Safety Compliance:

Adhere to all safety regulations and protocols to ensure a safe working environment.

- Wear appropriate personal protective equipment (PPE) at all times.

- Follow established safety procedures for operating machinery, handling materials, and performing maintenance tasks.

Interview Preparation Tips for a Liner Machine Operator:

1. Research the Company and Position:

Thoroughly research the company, its industry, and the specific role of a Liner Machine Operator within the organization.

- Visit the company website, read industry publications, and connect with current or former employees to gain insights about the company culture and job requirements.

- Identify the key skills and experiences sought by the hiring manager based on the job description and company profile.

2. Highlight Relevant Skills and Experience:

Tailor your resume and interview responses to showcase your relevant skills and experience that align with the job responsibilities.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Use action verbs and technical language to describe your proficiency in operating liner machines, monitoring production quality, and performing maintenance tasks.

3. Prepare for Technical Questions:

Anticipate technical questions related to liner machine operation, troubleshooting, and quality control.

- Review technical concepts, such as basis weight, moisture content, and web tension control.

- Prepare examples of how you handled technical challenges or implemented improvements to optimize machine performance.

4. Practice Common Interview Questions:

Prepare for common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Craft concise, well-structured answers that highlight your qualifications and enthusiasm for the role.

- Consider using the STAR method (Situation, Task, Action, Result) to provide specific examples that demonstrate your skills.

5. Ask Thoughtful Questions:

Prepare thoughtful questions to ask the interviewer, demonstrating your interest and engagement in the position.

- Inquire about the company’s production goals, the latest technologies used in liner machine operation, or the opportunities for professional development.

- Asking well-informed questions shows that you are genuinely interested in the role and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Liner Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Liner Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.