Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ply Bander interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ply Bander so you can tailor your answers to impress potential employers.

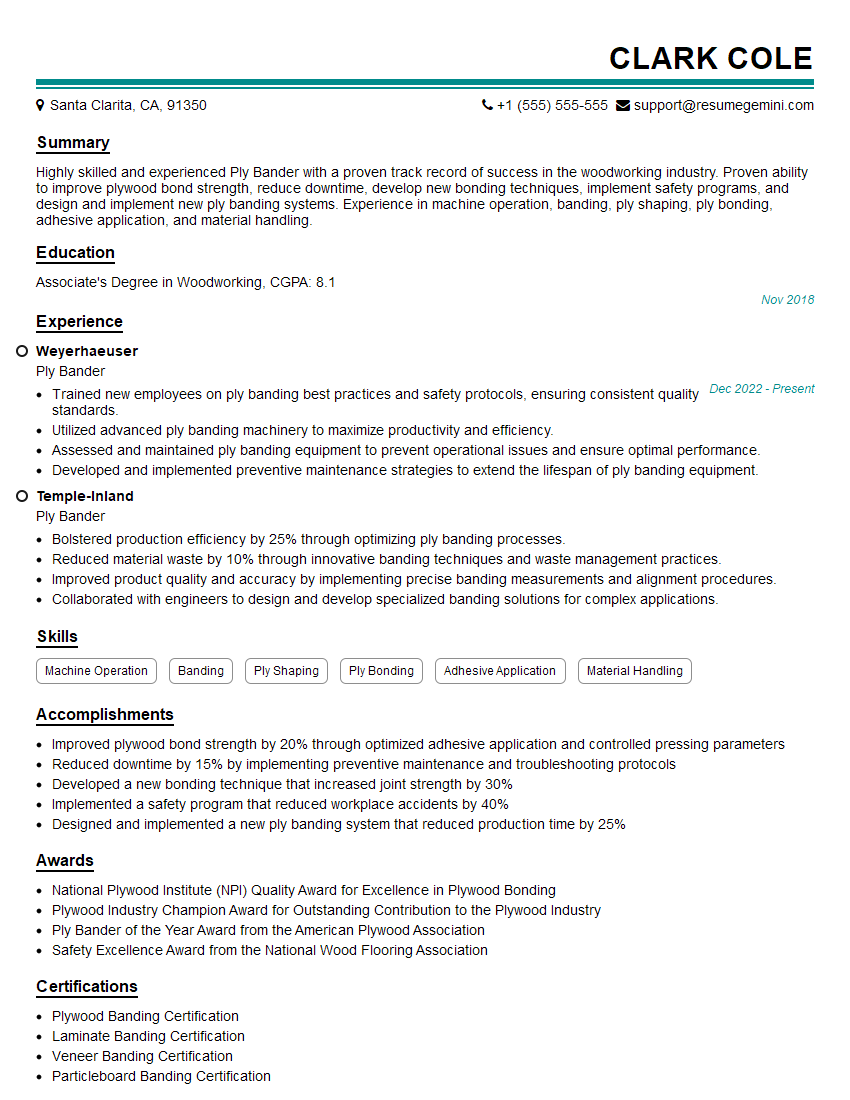

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ply Bander

1. Describe the key responsibilities of a Ply Bander?

As a Ply Bander, my primary responsibilities include:

- Preparing and operating ply banding machines to join and reinforce various types of materials, including wood, metal, and composites.

- Setting up and adjusting machines according to specified requirements, ensuring optimal performance and efficiency.

- Inspecting and maintaining equipment to identify and resolve any issues promptly, minimizing downtime.

- Following established procedures and safety protocols to maintain a safe and productive work environment.

- Collaborating with team members to achieve production goals and ensure timely completion of projects.

2. What types of materials have you worked with as a Ply Bander?

Throughout my experience, I have had the opportunity to work with a wide range of materials, including:

- Various types of lumber, such as plywood, MDF, and hardwoods

- Sheet metal and aluminum

- Composite materials like fiberglass and carbon fiber

- Specialized materials such as honeycomb panels and structural foams

3. Explain the process of ply banding and how you ensure the quality of the bond?

Ply banding typically involves the following steps:

- Selecting the appropriate banding material based on the specific application.

- Applying adhesive to the bonding surfaces and positioning the banding material.

- Using the ply banding machine to apply pressure and heat, creating a strong and durable bond.

Quality Assurance

- To ensure the quality of the bond, I adhere to strict quality control measures:

- Inspecting materials before use to identify any defects or inconsistencies.

- Monitoring pressure and temperature settings throughout the process to optimize bond strength.

- Conducting regular visual inspections and performing destructive testing as necessary to verify the integrity of the bond.

4. Describe the safety precautions you take when operating ply banding machines?

Safety is paramount when operating ply banding machines. I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Ensuring the machine is properly grounded and all guards are in place.

- Inspecting the machine before each use to identify any potential hazards.

- Never operating the machine without proper training and authorization.

- Reporting any accidents or near misses promptly to the supervisor.

5. Explain how you handle troubleshooting and maintenance of ply banding machines?

Troubleshooting and maintenance are crucial to ensure optimal performance and prevent costly downtime.

Troubleshooting

- I follow a systematic approach to troubleshooting:

- Identifying the problem by observing symptoms and analyzing error messages.

- Consulting with colleagues and technical documentation to determine the root cause.

- Implementing appropriate corrective actions to resolve the issue promptly.

Maintenance

- Regular maintenance is essential:

- Performing daily inspections and cleaning the machine to prevent debris buildup.

- Lubricating moving parts according to the manufacturer’s recommendations.

- Scheduling periodic maintenance checks and repairs to ensure longevity and reliability.

6. Describe your experience with different types of ply banding machines?

I have worked with various types of ply banding machines, including:

- Manual and automatic machines

- Machines designed for specific materials, such as wood or metal banding

- Machines with advanced features, such as programmable controls and automated feeding systems

7. Explain how you ensure the accuracy and precision of ply banding operations?

Accuracy and precision are essential in ply banding. I employ these techniques to achieve optimal results:

- Using precision measuring tools to ensure proper alignment and placement of materials.

- Fine-tuning machine settings to achieve the desired pressure and temperature for a strong bond.

- Conducting regular calibrations and inspections to maintain the accuracy of machines.

- Implementing quality control measures to verify the dimensions and tolerances of finished products.

8. Describe your experience with different types of adhesives used in ply banding?

I have experience working with a variety of adhesives used in ply banding, including:

- Water-based adhesives

- Solvent-based adhesives

- Hot-melt adhesives

- Pressure-sensitive adhesives

9. Explain how you handle working in a fast-paced production environment?

In fast-paced production environments, I maintain high levels of productivity and efficiency through:

- Prioritizing tasks and managing my time effectively.

- Working independently and as part of a team to meet deadlines.

- Staying focused and maintaining attention to detail, even under pressure.

- Communicating proactively to ensure smooth workflow and minimize interruptions.

10. Describe your understanding of industry standards and best practices related to ply banding?

I stay up-to-date with industry standards and best practices by:

- Attending industry events and conferences.

- Reading trade publications and technical articles.

- Consulting with experts and manufacturers.

Implementation

- In my work, I apply best practices to:

- Maximize productivity and efficiency.

- Ensure the quality and durability of ply banded products.

- Minimize waste and environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ply Bander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ply Bander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ply Bander is responsible for bending and forming plywood and other materials accurately and efficiently using a ply bender machine, to create structural or decorative elements for various construction projects.

1. Plywood Bending and Forming

Manually feed plywood or other materials into the ply bender machine.

- Set up and adjust machine parameters based on material thickness, desired bend radius, and temperature requirements.

- Monitor the bending process to ensure accurate and uniform bending.

- Unload formed plywood from the machine and inspect for quality and adherence to specifications.

2. Machine Operation and Maintenance

Operate and maintain the ply bender machine according to manufacturer’s instructions.

- Perform regular machine inspections and make necessary adjustments for optimal performance.

- Identify and troubleshoot machine malfunctions and implement corrective actions.

- Keep the machine and surrounding work area clean and organized.

3. Material Handling and Storage

Handle and store plywood and other materials safely and efficiently.

- Unload and stack plywood sheets according to specified sizes and thicknesses.

- Maintain inventory and ensure availability of materials for bending operations.

- Follow proper storage procedures to prevent damage or warping of materials.

4. Quality Control and Safety

Adhere to established quality standards and safety regulations.

- Inspect bent plywood for accuracy, dimensions, and surface quality.

- Use proper personal protective equipment (PPE) during work operations.

- Follow all safety protocols and report any potential hazards or accidents.

Interview Tips

1. Research the Company and Position

thoroughly research the company’s website and industry publications to understand their business, culture, and the specific role you are applying for.

- Prepare questions about the company’s products, services, and future plans.

- Review the job description carefully and identify the key skills and experience required.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your relevant skills and experience.

- Be prepared to discuss your knowledge of ply bending techniques and machine operation.

- Provide examples of your ability to work independently and as part of a team.

3. Showcase Your Skills and Experience

Use the STAR method (Situation, Task, Action, Result) to effectively communicate your experiences.

- Emphasize your ability to handle multiple tasks, meet deadlines, and work under pressure.

- Quantify your accomplishments whenever possible to demonstrate your impact.

4. Ask Insightful Questions

At the end of the interview, ask thoughtful questions to show your interest in the position and the company.

- Inquire about the company’s growth plans and how the position contributes to them.

- Ask about opportunities for professional development and training.

5. Follow Up Professionally

Within 24 hours of the interview, send a thank-you note to the interviewer, thanking them for their time and reiterating your interest in the position.

- Reiterate your key strengths and qualifications.

- Express your enthusiasm for the company and the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ply Bander role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.