Are you gearing up for a career in Tape Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tape Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

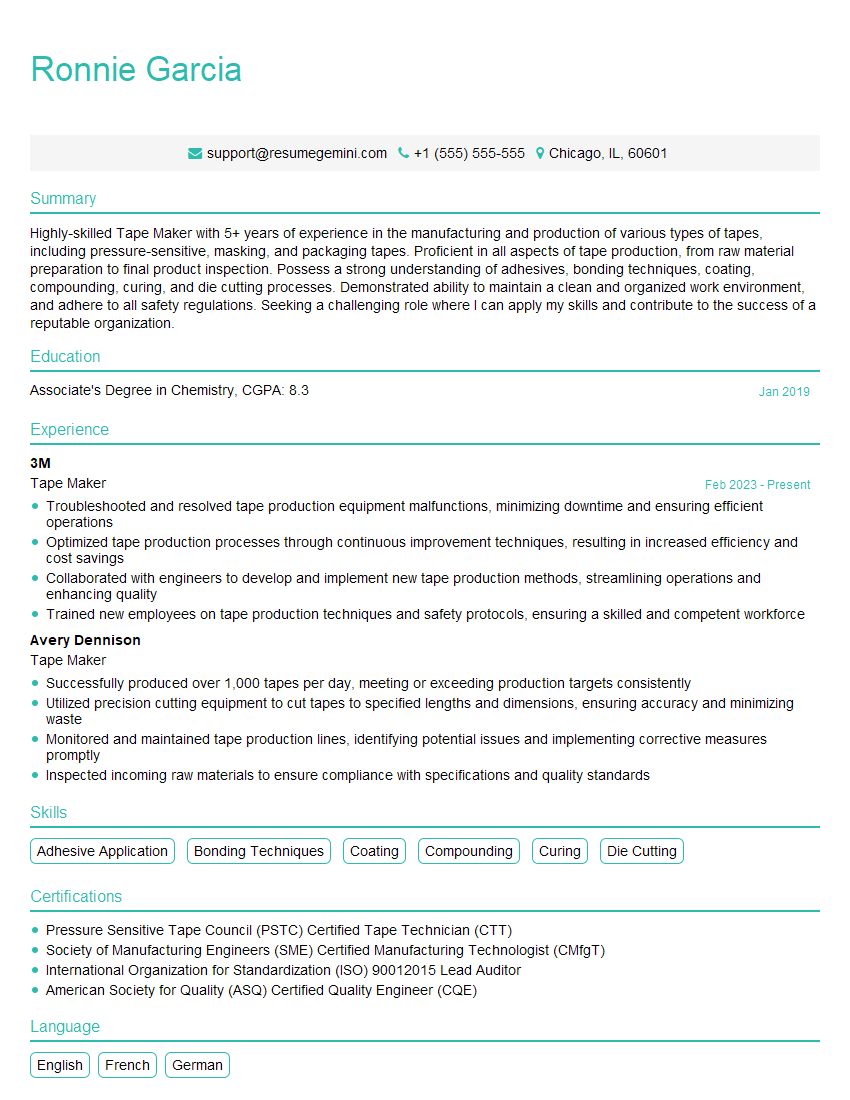

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tape Maker

1. What are the different types of tapes you have worked with?

In my previous role as a Tape Maker, I have worked with a diverse range of tapes, including:

- Adhesive tapes

- Backing tapes

- Electrical tapes

- Masking tapes

- Packaging tapes

2. Describe the process of tape manufacturing.

Raw Material Preparation

- Selecting and preparing the base material (e.g., paper, film, fabric)

- Applying adhesive to the base material

Tape Forming

- Coating the adhesive with a release agent

- Forming the tape into rolls or sheets

Finishing

- Slitting the tape into desired widths

- Packaging and labeling the tape

3. What are the key quality control measures involved in tape manufacturing?

To ensure the production of high-quality tapes, I follow these key quality control measures:

- Inspecting raw materials for defects

- Monitoring adhesive application and thickness

- Testing tape adhesion and tensile strength

- Checking for defects during tape forming and finishing

- Conducting regular performance tests on finished tapes

4. What are the common defects that occur in tape manufacturing, and how do you address them?

Common defects in tape manufacturing include:

- Adhesion failure: I adjust adhesive formulation or application process.

- Wrinkling: I ensure proper tension control during tape forming.

- Tearing: I optimize base material selection and adhesive properties.

- Uneven coating: I calibrate coating equipment and monitor adhesive viscosity.

5. What are the advancements in tape manufacturing technology that you are aware of?

Recent advancements in tape manufacturing technology include:

- Automated tape forming and slitting machines for increased efficiency.

- Development of specialty tapes with unique properties (e.g., high-temperature resistance, biodegradability).

- Advanced adhesive formulations that enhance tape performance and durability.

6. How do you stay updated on the latest trends and innovations in tape manufacturing?

To keep abreast of industry advancements, I participate in:

- Industry conferences and trade shows

- Technical webinars and workshops

- Collaboration with tape manufacturers and suppliers

- Reading industry publications and research papers

7. What is the most challenging aspect of tape manufacturing, and how do you overcome it?

The most challenging aspect of tape manufacturing is ensuring consistent tape quality under varying production conditions:

- I implement rigorous quality control procedures throughout the manufacturing process.

- I work closely with the production team to optimize equipment and processes.

- I collaborate with suppliers to source high-quality raw materials.

8. How do you handle customer complaints regarding tape performance?

When handling customer complaints, I follow these steps:

- Investigate the complaint thoroughly to identify the root cause.

- Communicate effectively with the customer to understand their concerns.

- Develop and implement corrective actions to prevent recurrence.

- Document the complaint and resolution for future reference.

9. Describe a project where you implemented a new tape manufacturing process or technology.

In my previous role, I led the implementation of a new automated tape slitting machine:

- Researched and evaluated different machine options

- Planned and coordinated the machine installation

- Trained the production team on the new equipment

- Optimized the slitting process for improved efficiency and accuracy

10. What is your understanding of lean manufacturing principles, and how have you applied them in tape manufacturing?

Lean manufacturing principles aim to eliminate waste and improve efficiency:

- I implemented a 5S system to organize and streamline the workplace.

- I analyzed production processes to identify and eliminate bottlenecks.

- I established a continuous improvement program to identify and implement process enhancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tape Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tape Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tape Makers are responsible for the production and maintenance of various types of tapes, such as adhesive tapes, masking tapes, and packaging tapes.

1. Operating Machinery

Operate and maintain tape-making machinery, ensuring that it is in good working order and that tapes are produced according to specifications.

- Set up and adjust machines to produce tapes of different widths, thicknesses, and materials.

- Monitor machines during operation to identify and correct any problems that may occur.

2. Preparing Raw Materials

Prepare raw materials, such as paper, film, and adhesive, for tape production.

- Measure and cut raw materials to the required dimensions.

- Apply adhesive to the raw materials using a variety of methods, such as rollers or spreaders.

3. Inspecting Tapes

Inspect finished tapes to ensure that they meet quality standards and specifications.

- Check the tapes for defects, such as tears, wrinkles, or uneven edges.

- Measure the tapes to ensure that they are the correct width, thickness, and length.

4. Packaging and Shipping Tapes

Package and ship finished tapes to customers.

- Pack tapes in boxes or rolls, ensuring that they are secure and protected from damage.

- Label and ship tapes to customers according to their orders.

Interview Tips

To ace the interview for a Tape Maker position, it is important to highlight your skills and experience in operating tape-making machinery, preparing raw materials, inspecting tapes, and packaging and shipping tapes. Here are some tips to help you prepare for the interview:

1. Research the Company

Before the interview, research the company and their products. This will show the interviewer that you are interested in the position and that you have taken the time to learn about their business.

- Visit the company’s website to learn about their history, mission, and products.

- Read news articles and press releases about the company to stay up-to-date on their latest developments.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you may be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Brainstorm a list of potential interview questions.

- Write out your answers to these questions and practice saying them out loud.

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience in operating tape-making machinery, preparing raw materials, inspecting tapes, and packaging and shipping tapes. Quantify your accomplishments whenever possible to provide the interviewer with concrete evidence of your abilities.

- For example, you could say “I have over 5 years of experience operating tape-making machinery and have consistently met or exceeded production targets.”

- Or, you could say “I am proficient in preparing raw materials for tape production, including measuring and cutting raw materials and applying adhesive.”

4. Be Professional and Enthusiastic

Throughout the interview, it is important to be professional and enthusiastic. Dress appropriately, arrive on time, and make eye contact with the interviewer. Show the interviewer that you are interested in the position and that you are confident in your abilities.

- Be polite and respectful to the interviewer and answer their questions thoughtfully and thoroughly.

- Ask questions at the end of the interview to show that you are interested in the position and that you are eager to learn more about the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tape Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!