Are you gearing up for an interview for a Coring Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coring Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

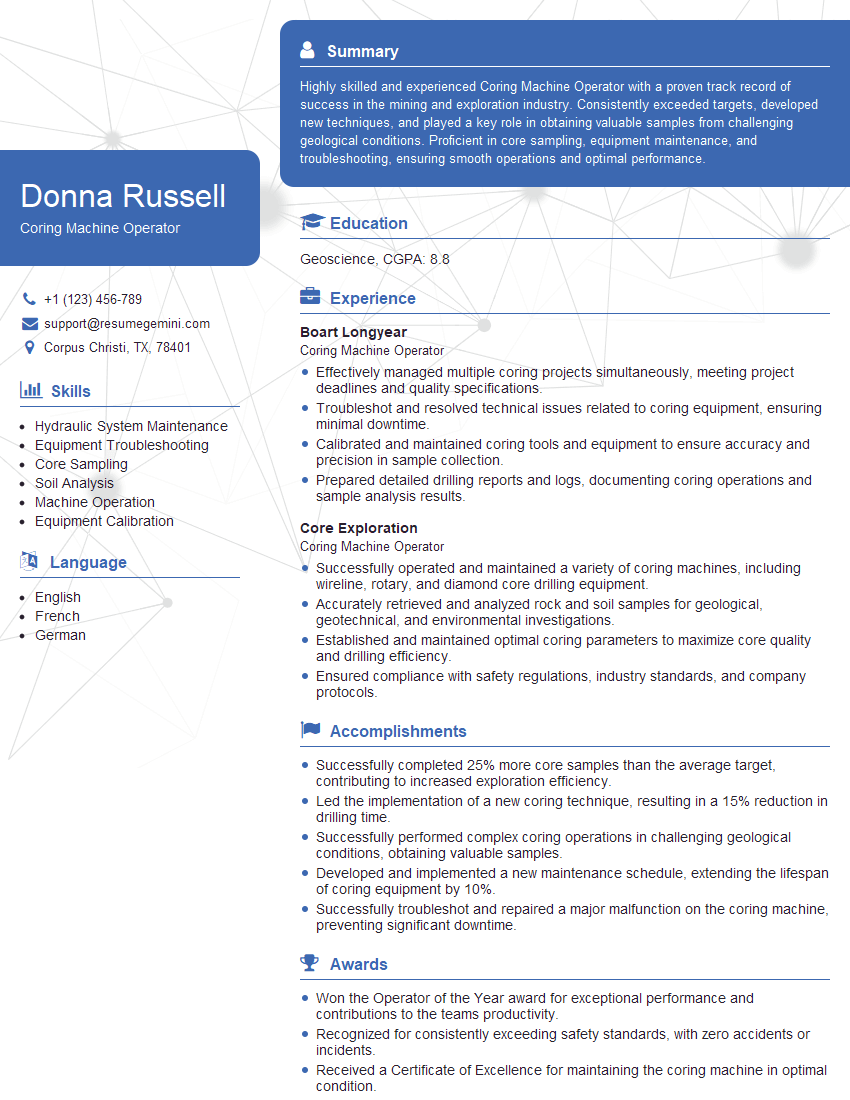

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coring Machine Operator

1. Explain the basic principles of a coring machine?

- A coring machine is a drilling rig that uses a hollow drill bit to extract a core sample of the rock formation being drilled.

- The core sample is used to determine the geological composition of the formation and to identify any potential resources, such as oil or gas.

2. What are the different types of coring machines?

- There are two main types of coring machines: rotary coring machines and percussion coring machines.

- Rotary coring machines use a rotating drill bit to cut through the rock formation, while percussion coring machines use a hammering action to break the rock into smaller pieces.

3. What are the factors that affect the performance of a coring machine?

- The performance of a coring machine is affected by a number of factors, including the type of rock formation being drilled, the size of the core sample being extracted, and the speed at which the drill bit is rotating.

- Other factors that can affect the performance of a coring machine include the weight of the drill bit, the amount of water being used to cool the drill bit, and the type of drilling fluid being used.

4. What are the safety precautions that must be taken when operating a coring machine?

- When operating a coring machine, it is important to take a number of safety precautions to avoid injury.

- These precautions include wearing proper safety gear, such as gloves, earplugs, and a hard hat, and keeping the work area clean and free of tripping hazards.

5. What are the maintenance procedures that must be performed on a coring machine?

- To ensure the proper operation of a coring machine, it is important to perform regular maintenance procedures.

- These procedures include checking the oil level, greasing the moving parts, and inspecting the drill bit for wear and tear.

6. What are the troubleshooting procedures for a coring machine?

- If a coring machine is not operating properly, it is important to troubleshoot the problem to identify the cause.

- Some common troubleshooting procedures include checking the power supply, inspecting the drill bit for damage, and checking the water supply.

7. What are the different types of core samples that can be extracted using a coring machine?

- The type of core sample that can be extracted using a coring machine depends on the type of coring machine being used and the rock formation being drilled.

- Some common types of core samples include solid core samples, split core samples, and rotary core samples.

8. What are the applications of core samples?

- Core samples are used for a variety of applications, including geological exploration, geotechnical engineering, and environmental assessment.

- Core samples can be used to identify the presence of oil or gas, to determine the strength and stability of a rock formation, and to assess the potential for contamination.

9. Describe the process of coring a rock sample.

- The process of coring a rock sample involves using a coring machine to drill a hole into the rock formation and extracting a core sample.

- The coring machine uses a hollow drill bit to cut a cylindrical core sample from the rock formation.

- The core sample is then removed from the drill bit and examined to determine the geological composition of the formation.

10. What are the challenges of coring in different rock formations?

- Coring in different rock formations presents different challenges, such as hard rock formations, soft soil conditions, and unstable rock formations.

- Hard rock formations can be difficult to drill through, while soft soil conditions can make it difficult to extract the core sample.

- Unstable rock formations can pose a safety risk to the operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coring Machine Operators are responsible for operating and maintaining coring machines used in geotechnical and environmental investigations, mining, and construction. They ensure the safe and efficient operation of the machines to extract soil, rock, and other materials for testing and analysis.

1. Machine Operation

Operate coring machines to extract soil, rock, or other materials for testing and analysis.

- Select and install appropriate drill bits and coring tools.

- Monitor and adjust machine settings to ensure optimal performance.

2. Sample Collection and Handling

Collect and handle soil, rock, or other materials extracted using the coring machine.

- Label and store samples according to established protocols.

- Maintain accurate records of sample collection and handling.

3. Equipment Maintenance

Maintain and calibrate coring machines and associated equipment.

- Lubricate and clean machines as per manufacturer’s guidelines.

- Perform minor repairs and troubleshooting to ensure machine functionality.

4. Safety and Compliance

Follow established safety protocols and regulations related to coring operations.

- Wear appropriate personal protective equipment (PPE).

- Adhere to job site safety procedures to minimize risks.

5. Data Analysis and Reporting

Analyze data collected from coring operations and prepare reports.

- Interpret soil, rock, and other material properties based on samples collected.

- Generate clear and concise reports summarizing findings and observations.

Interview Tips

To ace your Coring Machine Operator interview, preparation is key. Here are some tips to help you make a strong impression:

1. Research the Company and Role

Thoroughly research the company and the specific role you are applying for. Understand their industry, values, and the responsibilities of the position. This knowledge will help you tailor your answers and demonstrate your interest in the opportunity.

2. Practice Your Answers

Anticipate common interview questions and practice your answers. Focus on highlighting your skills and experience relevant to the role. Use the STAR method (Situation, Task, Action, Result) to provide specific and detailed examples of your accomplishments.

3. Emphasize Safety and Compliance

Coring operations involve potential hazards. Emphasize your understanding of safety protocols, adherence to regulations, and commitment to ensuring a safe work environment. Share examples of your previous safety practices and any certifications or training you have obtained.

4. Showcase Your Technical Skills

Highlight your proficiency in operating coring machines, selecting appropriate drilling tools, and handling samples. Discuss any technical knowledge or expertise you possess that aligns with the role’s requirements. If possible, quantify your accomplishments and provide data-driven evidence of your skills.

5. Prepare Relevant Questions

Preparing thoughtful questions for the interviewer demonstrates your interest and engagement. Ask questions about the company’s coring operations, project involvement, or career growth opportunities within the organization. This not only shows your curiosity but also gives you valuable insights into the company and the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coring Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!