Are you gearing up for an interview for a Glass Cleaning Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Cleaning Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

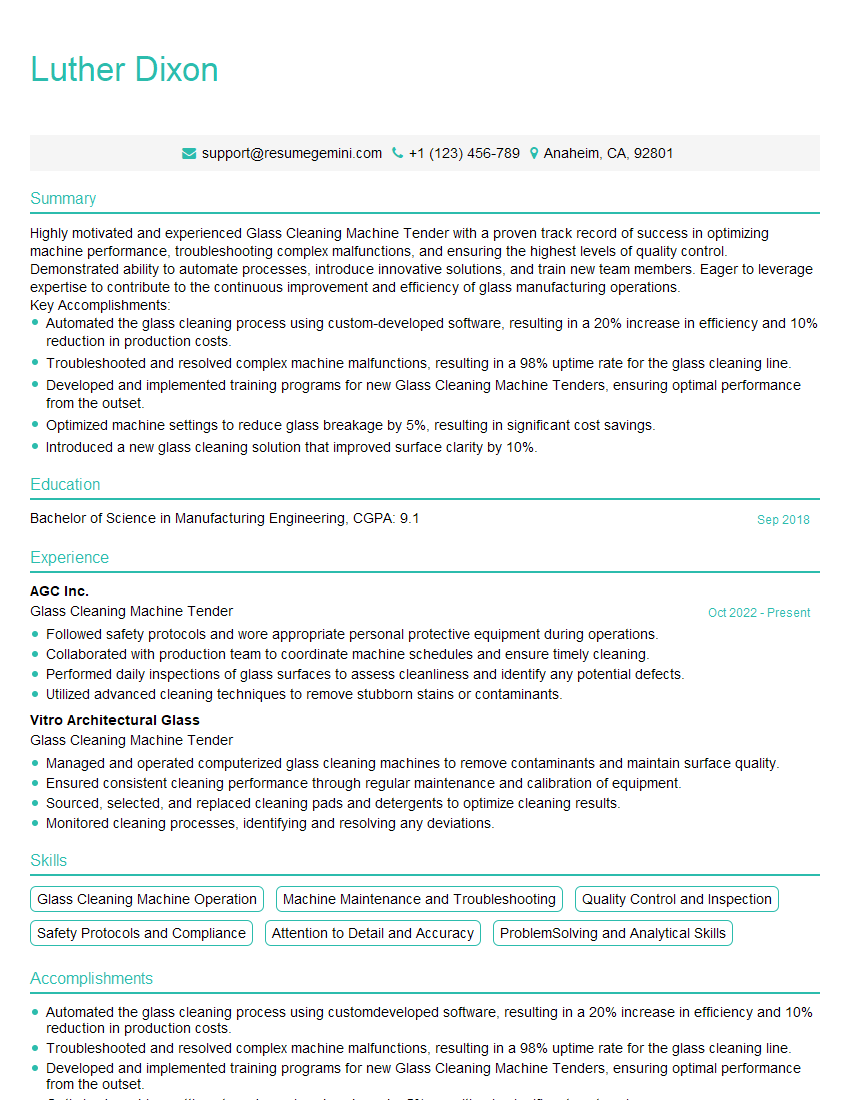

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Cleaning Machine Tender

1. Explain the process of cleaning glass surfaces using an automated glass cleaning machine?

The process of cleaning glass surfaces using an automated glass cleaning machine involves several steps:

- Pre-wash: The machine first applies a pre-wash solution to the glass surface to loosen dirt and debris.

- Brushing: Soft brushes on the machine gently scrub the glass surface to remove loose dirt and contaminants.

- Rinsing: After brushing, the machine rinses the glass surface with clean water to remove any remaining dirt and soap residue.

- Drying: The machine uses heated air or a squeegee system to dry the glass surface, leaving it spotless and streak-free.

2. Describe the different types of brushes used in glass cleaning machines and their specific purposes?

There are several types of brushes used in glass cleaning machines, each with a specific purpose:

Nylon brushes:

- Suitable for general-purpose cleaning and removing light dirt and dust.

- Soft and gentle on glass surfaces, preventing scratches or damage.

Polishing brushes:

- Used for polishing and finishing the glass surface, leaving it with a streak-free shine.

- Made of fine, delicate materials to avoid scratching.

Abrasive brushes:

- Designed for heavy-duty cleaning, removing tough stains or dirt buildup.

- Use caution when using abrasive brushes, as they can potentially scratch the glass if not used properly.

3. Explain how to adjust the cleaning speed and pressure settings of a glass cleaning machine to optimize performance?

Adjusting the cleaning speed and pressure settings of a glass cleaning machine is crucial for optimal performance:

- Cleaning speed: The speed at which the machine moves across the glass surface should be adjusted based on the level of dirt and the desired cleaning result. A faster speed is suitable for lightly soiled surfaces, while a slower speed is better for heavily soiled areas.

- Cleaning pressure: The pressure applied by the brushes should be adjusted according to the type of glass and the amount of dirt. Higher pressure may be necessary for tougher stains, but excessive pressure should be avoided to prevent damage to the glass.

4. Describe the maintenance procedures for an automated glass cleaning machine, including daily, weekly, and monthly tasks?

Regular maintenance is essential to ensure the optimal performance and longevity of an automated glass cleaning machine:

Daily tasks:

- Inspect the machine for any visible damage or wear.

- Clean the brushes and squeegees to remove dirt and debris buildup.

- Check the water supply and detergent levels.

Weekly tasks:

- Thoroughly clean the entire machine, including the brushes, squeegees, and water tank.

- Inspect the electrical components and wiring for any loose connections or damage.

Monthly tasks:

- Lubricate all moving parts to ensure smooth operation.

- Check and replace worn or damaged brushes and squeegees.

- Calibrate the machine’s sensors and settings for optimal performance.

5. Explain how to troubleshoot common problems that may occur with an automated glass cleaning machine?

Troubleshooting common problems with an automated glass cleaning machine requires a systematic approach:

- Identify the problem: Observe the machine’s behavior, error messages, or any unusual sounds or smells.

- Check the basics: Ensure that the machine is properly plugged in, the water supply is adequate, and the detergent level is sufficient.

- Inspect the brushes and squeegees: Look for any wear, damage, or excessive dirt buildup that may hinder cleaning.

- Check the sensors: Ensure that the sensors are clean and not obstructed, as they provide feedback to the machine’s control system.

- Refer to the manufacturer’s manual: The manual often contains troubleshooting guides and specific instructions for resolving common problems.

6. Describe the safety precautions that should be followed when operating an automated glass cleaning machine?

To ensure a safe operating environment, the following precautions should be taken:

- Wear appropriate safety gear, including gloves and protective eyewear.

- Keep the work area clean and free of obstacles to prevent slips or falls.

- Never reach into the machine while it is in operation.

- Use caution when handling cleaning solutions, as they may contain chemicals.

- Follow the manufacturer’s instructions for proper setup, operation, and maintenance.

7. How do you handle situations where the automated glass cleaning machine malfunction or breaks down?

In case of a malfunction or breakdown:

- Safety first: Immediately turn off the machine and unplug it from the power source.

- Assess the situation: Identify the cause of the problem if possible.

- Refer to the manual: Check the manufacturer’s manual for troubleshooting instructions.

- Contact a qualified technician: If the issue cannot be resolved, contact a qualified technician for professional repair.

8. Explain the importance of maintaining accurate records of the machine’s maintenance and repairs?

Maintaining accurate maintenance and repair records is crucial for:

- Tracking performance: Records help monitor the machine’s performance over time, identify any recurring issues, and plan for preventive maintenance.

- Warranty purposes: Some manufacturers require maintenance records as proof of proper upkeep for warranty claims.

- Legal compliance: In some industries, regulations may require documentation of maintenance activities for safety and liability reasons.

9. Describe how you would train a new employee on the operation and maintenance of an automated glass cleaning machine?

Training a new employee would involve:

- Hands-on demonstration: Showing the employee how to operate the machine safely and efficiently.

- Explanation of controls: Thoroughly explaining the functions of all controls, dials, and indicators.

- Maintenance procedures: Training the employee on daily, weekly, and monthly maintenance tasks.

- Troubleshooting: Providing guidance on how to identify and resolve common problems.

- Safety protocols: Emphasizing the importance of following safety precautions.

10. How do you stay updated with the latest advancements in glass cleaning technology?

To stay updated with the latest advancements:

- Attend industry events: Participate in conferences, trade shows, and workshops to learn about new technologies.

- Read industry publications: Subscribe to trade magazines and online resources for the latest news and developments.

- Connect with manufacturers: Engage with equipment manufacturers to learn about their latest products and innovations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Cleaning Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Cleaning Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glass Cleaning Machine Tender is responsible for the operation and maintenance of glass cleaning machines in a manufacturing or industrial setting.

1. Machine Operation

Tender, monitors, and adjusts glass cleaning machines to ensure optimal performance.

- Loads and unloads glass sheets or items into and out of the machine.

- Sets up and adjusts machine parameters, such as speed, temperature, and pressure.

- Monitors the machine’s operation and makes adjustments as needed to maintain efficiency.

2. Machine Maintenance

Performs routine maintenance and repairs on glass cleaning machines to prevent breakdowns and ensure longevity.

- Inspects machines regularly and identifies potential problems.

- Cleans and lubricates machine components as per the manufacturer’s guidelines.

- Replaces worn or damaged parts to maintain optimal machine performance.

3. Quality Control

Inspects cleaned glass sheets or items to ensure they meet quality standards.

- Checks for scratches, blemishes, or other defects.

- Rejects non-conforming glass sheets or items and reports any quality issues to supervisors.

- Maintains records of quality inspections and any corrective actions taken.

4. Safety and Compliance

Follows safety protocols and adheres to environmental regulations related to glass cleaning operations.

- Wears appropriate safety gear, such as gloves, goggles, and earplugs.

- Handles and disposes of cleaning chemicals and solvents safely.

- Complies with all applicable environmental regulations and waste management procedures.

Interview Tips

To prepare for an interview for a Glass Cleaning Machine Tender position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and the specific requirements of the Glass Cleaning Machine Tender role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Network with individuals in the industry.

2. Practice Your Answers

Prepare answers to common interview questions, such as:

- Tell me about your experience operating and maintaining glass cleaning machines.

- How do you ensure the quality of cleaned glass sheets or items?

- What safety protocols do you follow in your work?

3. Prepare for Technical Questions

Expect questions related to the technical aspects of glass cleaning machines, such as:

- Explain the different types of glass cleaning machines and their applications.

- Describe the maintenance procedures you follow to keep a glass cleaning machine in optimal condition.

- How do you troubleshoot and resolve common problems with glass cleaning machines?

4. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview.

- Quantify your achievements using specific examples.

- Use action verbs and industry-specific terminology.

- Tailor your answers to the specific job requirements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Cleaning Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!