Are you gearing up for an interview for a Metal Washing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Washing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

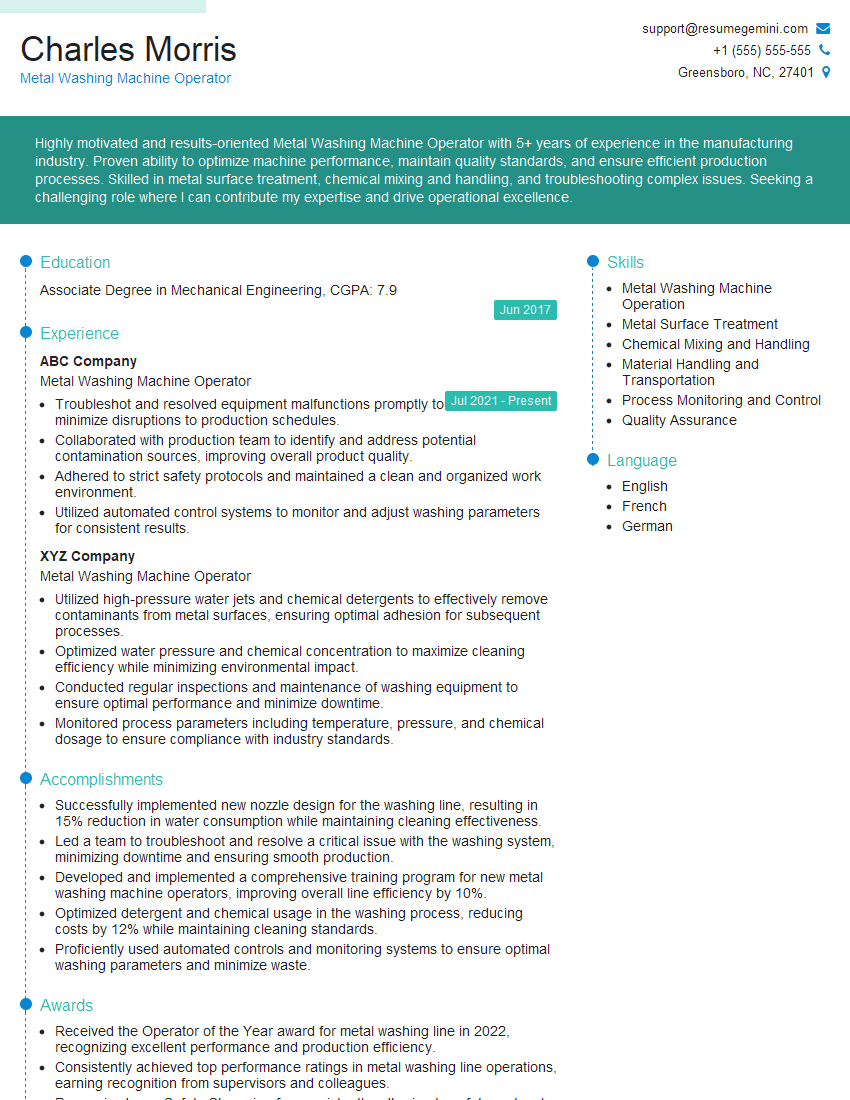

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Washing Machine Operator

1. What are the key responsibilities of a Metal Washing Machine Operator?

The key responsibilities of a Metal Washing Machine Operator typically include:

- Operating and maintaining metal washing machines to clean metal parts and components

- Loading and unloading parts from the machines

- Monitoring the machines to ensure they are functioning properly

- Adjusting machine settings as needed

- Troubleshooting and resolving machine malfunctions

- Maintaining a clean and safe work area

- Following safety protocols and procedures

2. What types of metal washing machines are you familiar with?

I am familiar with various types of metal washing machines, including:

Solvent Cleaning Machines

- Vapor degreasers

- Immersion cleaners

- Ultrasonic cleaners

Aqueous Cleaning Machines

- Spray washers

- Dip tanks

- Ultrasonic cleaners

Mechanical Cleaning Machines

- Tumbling barrels

- Vibratory cleaners

- Abrasive blasters

3. What are the different types of cleaning solutions used in metal washing machines?

The types of cleaning solutions used in metal washing machines vary depending on the type of machine, the metal being cleaned, and the desired results. Some common types of cleaning solutions include:

- Solvents (e.g., trichloroethylene, perchloroethylene)

- Aqueous solutions (e.g., water-based detergents, alkaline cleaners)

- Acids (e.g., hydrochloric acid, sulfuric acid)

- Bases (e.g., sodium hydroxide, potassium hydroxide)

4. What is the importance of proper maintenance of metal washing machines?

Proper maintenance of metal washing machines is crucial for several reasons:

- Ensures optimal performance and efficiency

- Reduces the risk of breakdowns and malfunctions

- Extends the lifespan of the equipment

- Maintains a safe working environment for operators

- Prevents contamination of parts and components

5. What are the safety precautions that should be taken when operating a metal washing machine?

To ensure safety when operating a metal washing machine, it is essential to follow these precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator

- Ensure proper ventilation to prevent exposure to harmful fumes

- Never operate a machine with a known malfunction

- Follow all manufacturer’s instructions and safety guidelines

- Be aware of the potential hazards associated with the cleaning solutions being used

- Know the emergency procedures in case of an accident

6. How do you troubleshoot common problems with metal washing machines?

When troubleshooting common problems with metal washing machines, I typically follow these steps:

- Identify the problem and its symptoms

- Check for any obvious issues, such as leaks or loose connections

- Refer to the manufacturer’s manual for troubleshooting guidance

- Perform basic maintenance tasks, such as cleaning filters or checking fluid levels

- If the problem persists, contact a qualified technician for assistance

7. What are your quality control procedures for ensuring that parts are properly cleaned?

To ensure the quality of cleaned parts, I adhere to the following procedures:

- Visually inspect parts before and after cleaning to check for cleanliness and damage

- Use measuring instruments, such as calipers or gauges, to verify critical dimensions

- Perform tests, such as water break tests or salt spray tests, to assess the effectiveness of the cleaning process

- Maintain records of all quality control checks and results

8. What is your experience with different types of metal finishes?

I have experience working with various types of metal finishes, including:

- Bare metal finishes (e.g., steel, aluminum, stainless steel)

- Painted finishes (e.g., powder coating, liquid painting)

- Plated finishes (e.g., zinc plating, chrome plating)

- Anodized finishes (e.g., aluminum anodizing)

9. How do you handle situations where parts are not cleaned to the required specifications?

When parts are not cleaned to the required specifications, I take the following steps:

- Identify the cause of the problem (e.g., incorrect cleaning parameters, malfunctioning equipment)

- Make necessary adjustments to the cleaning process or equipment

- Re-clean the parts to ensure they meet the specifications

- Document the issue and corrective actions taken

- Inform the supervisor or quality control department

10. What are your goals for continuous improvement in your role as a Metal Washing Machine Operator?

My goals for continuous improvement include:

- Improving the efficiency and productivity of the cleaning process

- Reducing the risk of errors and defects

- Staying up-to-date with the latest cleaning technologies and best practices

- Identifying opportunities to reduce costs and waste

- Enhancing my skills and knowledge through training and development programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Washing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Washing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Washing Machine Operators play a crucial role in the manufacturing industry by ensuring the cleanliness and quality of metal parts. Their responsibilities encompass various aspects of the metal cleaning process, including:

1. Loading and Unloading Metal Parts

Operators are responsible for placing metal parts inside the washing machine and removing them once the cleaning cycle is complete. They ensure that parts are properly positioned and secured to prevent damage during the cleaning process.

2. Operating and Monitoring Washing Machines

Operators follow established procedures to operate and monitor washing machines. They set the correct cleaning parameters, including temperature, pressure, and chemical concentrations. They also monitor the progress of the cleaning cycle and make adjustments as needed.

3. Maintaining and Inspecting Equipment

Maintaining the washing machines is essential to ensure their proper operation. Operators perform routine maintenance tasks, such as cleaning nozzles, checking filters, and lubricating moving parts. They also inspect equipment for any signs of damage or wear and report any issues promptly.

4. Ensuring Quality Standards

Operators play a critical role in ensuring the quality of cleaned metal parts. They visually inspect parts after cleaning to verify that they are free of contaminants and meet required specifications. They also perform quality control tests, such as measuring surface roughness and checking for corrosion resistance, to validate the effectiveness of the cleaning process.

Interview Tips

Preparing thoroughly for an interview is essential for Metal Washing Machine Operator candidates. Here are some tips to help you ace the interview and secure the job:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will demonstrate your interest and knowledge of the industry. Learn about the company’s products, services, and values. Also, review the job description carefully to understand the key responsibilities and qualifications.

2. Practice Your Answers

Practicing your answers to common interview questions can boost your confidence and make you feel more prepared. Prepare for questions about your experience operating washing machines, your knowledge of metal cleaning processes, and your attention to detail. Consider using the STAR method to structure your answers, which involves describing a Situation, the Task you performed, the Action you took, and the Result of your actions.

3. Highlight Your Safety Knowledge

Employers prioritize safety in manufacturing environments. Emphasize your understanding of safety regulations and your commitment to following proper procedures. Describe your experience in handling hazardous chemicals and using safety equipment. Mention any safety training certifications you possess.

4. Be Enthusiastic and Professional

During the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you are eager to learn, contribute, and take on the responsibilities of the role. Dress professionally and arrive on time for the interview to make a good first impression.

5. Ask Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions about the company’s operations, the training provided to new employees, and opportunities for professional development. This shows that you are genuinely interested in the company and the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Metal Washing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Metal Washing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.