Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pickling Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

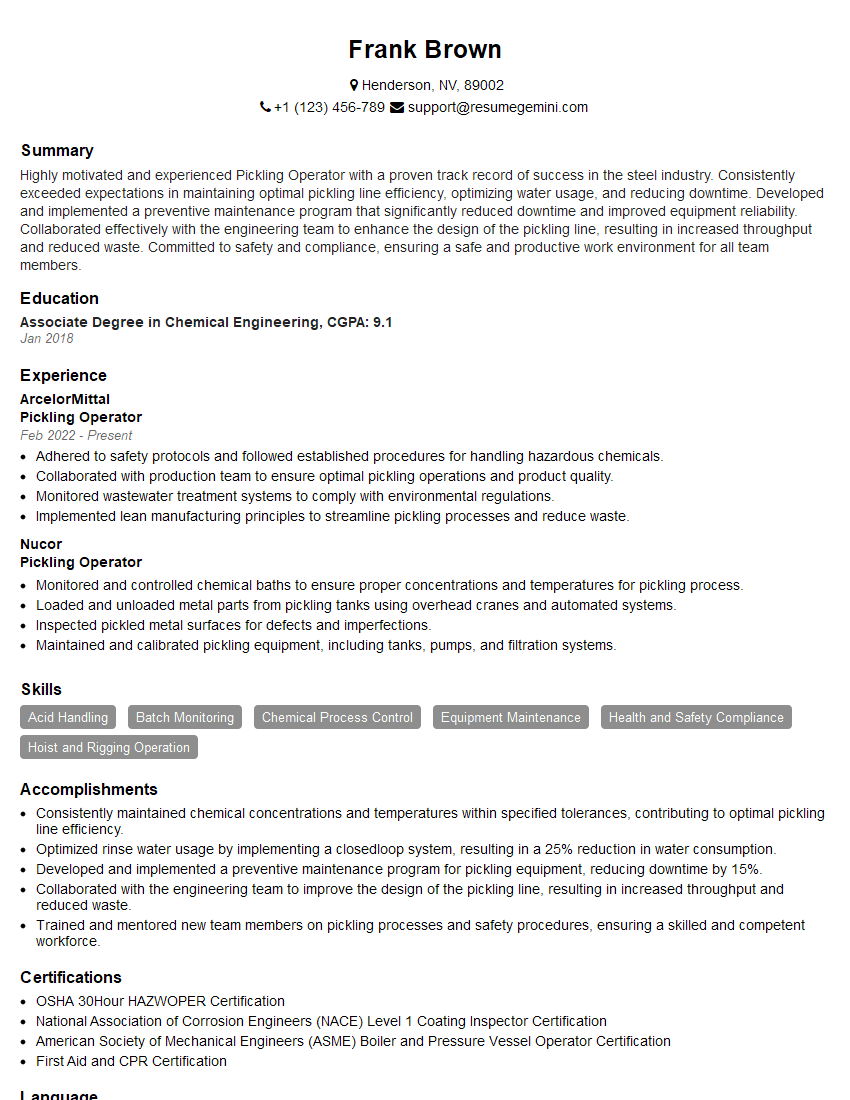

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pickling Operator

1. Describe the primary responsibilities of a Pickling Operator?

The primary responsibilities of a Pickling Operator typically include:

- Operating and monitoring pickling equipment, including tanks, pumps, and conveyors.

- Preparing and maintaining pickling solutions, ensuring proper chemical concentrations and temperatures.

- Loading and unloading metal parts into and out of pickling tanks, using hoists or other equipment.

2. What are the key safety procedures to follow when working with pickling solutions?

General Safety Measures

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and aprons.

- Adhering to designated work areas and avoiding contact with chemicals outside of designated zones.

- Following established lockout/tagout procedures to prevent accidental equipment activation.

Chemical Safety

- Handling acids and bases with extreme care, avoiding direct contact and spills.

- Neutralizing spills immediately using designated spill kits and notifying supervisors.

- Ventilating work areas to prevent the accumulation of hazardous fumes.

3. Explain the different types of pickling solutions and their applications?

Pickling solutions are categorized based on their chemical composition and intended use:

- Sulfuric Acid Pickling: Removes scale, rust, and other impurities from ferrous metals.

- Hydrochloric Acid Pickling: Similar to sulfuric acid pickling but less corrosive, used on stainless steel and copper alloys.

- Nitric Acid Pickling: Passivates stainless steel surfaces, enhancing corrosion resistance.

- Citric Acid Pickling: Used for light cleaning and descaling of non-ferrous metals.

4. How do you determine the optimal pickling time and temperature for different metals?

The optimal pickling time and temperature depend on the metal type and the desired surface finish:

- Metal Hardness: Harder metals require longer pickling times and higher temperatures.

- Surface Contamination: Heavily contaminated metals need longer pickling times.

- Desired Finish: A brighter finish requires longer pickling times and higher temperatures.

5. What are the common problems encountered during pickling and how do you troubleshoot them?

Common problems and troubleshooting steps include:

- Overpickling: Monitor pickling time and temperature closely to avoid excessive etching.

- Incomplete Pickling: Check solution concentration, temperature, and agitation to ensure effective cleaning.

- Metal Staining: Verify that the solution is properly maintained and free of contaminants.

- Equipment Malfunctions: Identify and repair any issues with tanks, pumps, or conveyors promptly.

6. How do you maintain the quality of pickling solutions?

Maintaining pickling solution quality involves:

- Regularly monitoring and adjusting solution concentration using titration or other methods.

- Filtering solutions to remove contaminants and suspended particles.

- Replenishing chemicals as needed to maintain optimal pickling performance.

- Following established waste disposal procedures for spent solutions.

7. Describe the environmental and safety regulations related to pickling operations?

Relevant regulations include:

- OSHA Hazard Communication Standard (HCS): Requires proper labeling and communication of chemical hazards.

- EPA Clean Water Act: Regulates wastewater discharge from pickling operations.

- EPA Resource Conservation and Recovery Act (RCRA): Governs the management and disposal of hazardous waste.

- Company-specific environmental policies: Ensuring compliance with internal standards for pollution prevention.

8. What are the advancements in pickling technology that have improved the process?

- Automated Pickling Lines: Reduce manual labor and increase efficiency.

- Ultrasonic Pickling: Enhances cleaning effectiveness and reduces pickling time.

- Electrochemical Pickling: Provides precise control over the pickling process and reduces chemical consumption.

- Environmentally Friendly Pickling Solutions: Minimize waste and reduce environmental impact.

9. How do you stay updated with the latest best practices and technologies in pickling?

- Attending industry conferences and workshops.

- Reading technical publications and research papers.

- Consulting with equipment manufacturers and solution providers.

- Participating in online forums and networking with other professionals.

10. Describe a situation where you successfully resolved a major issue related to pickling operations?

Provide a specific example of a problem encountered, the steps taken to analyze and identify the root cause, and the solution implemented to resolve the issue effectively.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pickling Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pickling Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pickling Operator is responsible for the operation of pickling lines in a steel mill or other metalworking facility. Pickling is the process of removing oxides and other impurities from metal surfaces using an acid solution. The Pickling Operator’s responsibilities include:

1. Loading and unloading metal coils

The Pickling Operator is responsible for loading and unloading metal coils onto and off of the pickling line. This involves using a crane or other lifting device to move the coils into and out of the line.

2. Operating the pickling line

The Pickling Operator is responsible for operating the pickling line. This involves setting up the line, monitoring the process, and making adjustments as needed. The operator also ensures that the line is running efficiently and that the metal is being properly pickled.

3. Maintaining the pickling line

The Pickling Operator is responsible for maintaining the pickling line. This involves inspecting the line for problems, cleaning and lubricating the equipment, and making repairs as needed. The operator also ensures that the line is safe to operate.

4. Quality control

The Pickling Operator is responsible for ensuring that the pickled metal meets the required specifications. This involves inspecting the metal for defects, such as scratches, dents, and corrosion. The operator also ensures that the metal is the correct thickness and hardness.

Interview Tips

Interviews can be stressful, but there are several actions you can take to prepare, such as researching, practicing, and dressing professionally. Here are some interview tips and tricks to help you ace your interview for a Pickling Operator position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific responsibilities of the Pickling Operator position. Research can be done on the company website or social media pages, as well as through reading industry news and articles.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions in advance. This will help you feel more confident and prepared during your interview.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed. Dressing professionally will show the interviewer that you are serious about the position and that you are respectful of their time.

4. Be confident and enthusiastic

Confidence is key in an interview. Make sure to maintain eye contact with the interviewer, speak clearly and concisely, and be enthusiastic about the position. Enthusiasm will show the interviewer that you are interested in the position and that you are eager to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pickling Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!