Feeling lost in a sea of interview questions? Landed that dream interview for Production Sanitizer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Production Sanitizer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

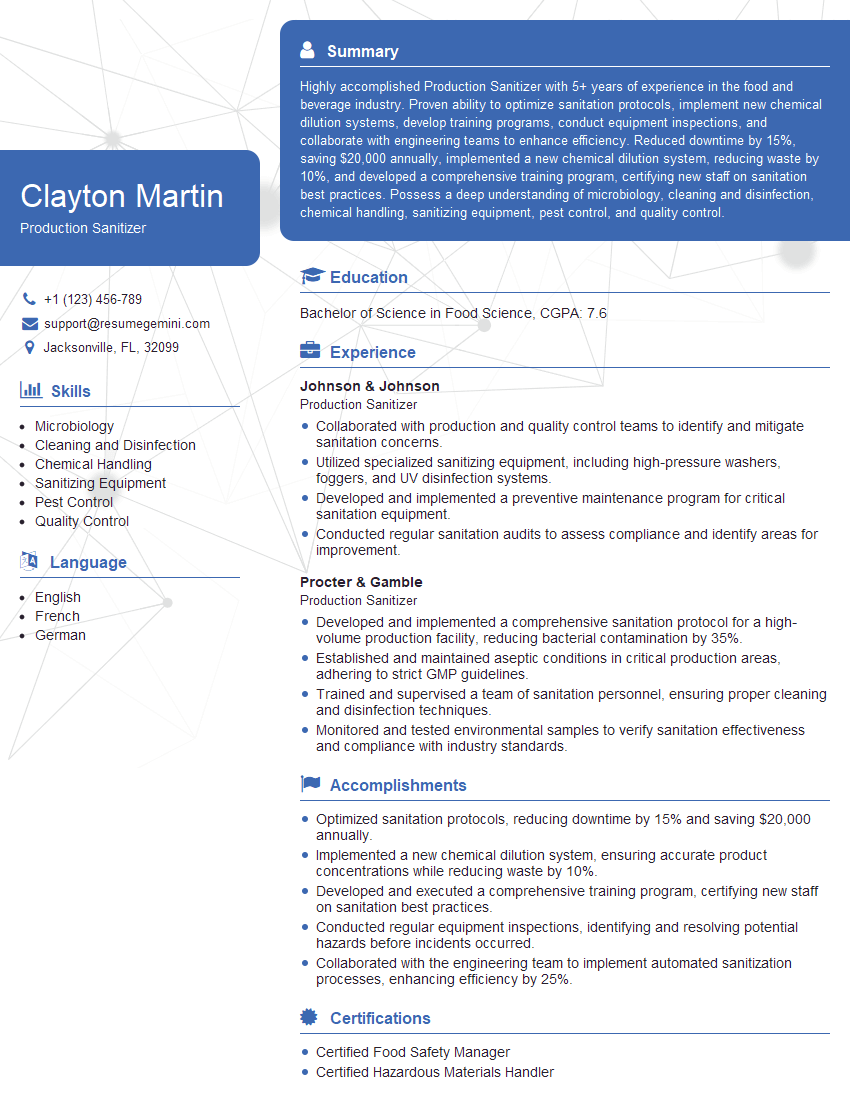

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Sanitizer

1. What are the key responsibilities of a Production Sanitizer in a manufacturing environment?

- Implement and maintain high levels of sanitation and hygiene throughout the production area.

- Adhere to all safety and regulatory guidelines for sanitation practices.

- Conduct regular inspections and monitoring of equipment, surfaces, and products to identify and address potential contamination risks.

- Use and maintain a variety of sanitizing agents and equipment effectively.

- Train and supervise other employees on proper sanitation procedures.

2. Describe the importance of adhering to sanitation protocols in a production facility.

- Prevents contamination and ensures the safety of products for consumers.

- Maintains the quality and integrity of products by minimizing the risk of spoilage or deterioration.

- Ensures compliance with industry regulations and standards for food safety and hygiene.

- Prevents legal liabilities and fines associated with non-compliance.

- Protects employees from exposure to harmful microorganisms and contaminants.

- Creates a safe and healthy work environment, reducing the risk of illness or injury.

Product safety and quality

Regulatory compliance

Employee health and safety

3. Explain the different methods of sanitation used in a production environment.

- Chemical sanitation: Using chemicals such as chlorine, quaternary ammonium compounds, and hydrogen peroxide to kill or inactivate microorganisms.

- Physical sanitation: Using heat, ultraviolet light, or filtration to remove or destroy microorganisms.

- Biological sanitation: Using beneficial microorganisms to compete with or neutralize harmful microorganisms.

4. How do you determine the appropriate sanitation method for a specific application?

- Consider the type and level of contamination.

- Assess the surface or material to be sanitized.

- Review regulatory requirements and industry best practices.

- Consult with experts in sanitation and microbiology.

5. What are the common challenges faced by Production Sanitizers?

- Maintaining consistent sanitation standards in a fast-paced production environment.

- Balancing the need for thorough sanitation with efficiency and cost-effectiveness.

- Staying up-to-date with evolving sanitation technologies and regulations.

- Ensuring the cooperation and compliance of employees with sanitation procedures.

6. How do you prioritize and allocate your time effectively as a Production Sanitizer?

- Establish a regular sanitation schedule based on risk assessment.

- Identify critical areas that require more frequent attention.

- Delegate tasks to other employees where appropriate.

- Use technology, such as automated sanitizing systems, to streamline processes.

7. What steps do you take to ensure the accuracy and effectiveness of your sanitation procedures?

- Follow written sanitation protocols and checklists.

- Regularly monitor and test the effectiveness of sanitizing agents.

- Calibrate and maintain equipment used for sanitation.

- Document all sanitation activities for traceability and records.

8. How do you handle situations where you encounter resistance or non-compliance with sanitation procedures from employees?

- Communicate the importance of sanitation and its impact on product safety and employee health.

- Provide training and support to employees on proper procedures.

- Enforce consequences for non-compliance in a fair and consistent manner.

- Seek support from supervisors or management if necessary.

9. Describe your experience using specific sanitation equipment or technologies.

- Automated sanitizing systems

- Ultraviolet disinfection systems

- Chemical dispensing and monitoring equipment

- Microbiological testing kits

10. What are some of the latest advancements in sanitation practices that you are aware of?

- Antimicrobial coatings and surfaces

- Biosensors for real-time contamination monitoring

- Data analytics for sanitation optimization

- Mobile apps for sanitation management

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Sanitizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Sanitizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Sanitizer is responsible for maintaining a clean and sanitized production environment. They follow prescribed cleaning and sanitation procedures to ensure the quality and safety of products.

1. Cleaning and Sanitizing

Ensures a clean and sanitary work environment by following established cleaning and sanitation procedures.

- Uses approved cleaning agents and equipment to clean and sanitize surfaces, equipment, and utensils.

- Inspects equipment and surfaces for cleanliness and sanitation, identifying and addressing any areas of concern.

2. Monitoring and Inspection

Monitors and inspects the production area to identify and address potential contamination risks.

- Takes swabs and performs ATP tests to monitor the cleanliness of surfaces and equipment.

- Inspects products and packaging for signs of contamination or damage.

3. Documentation and Reporting

Maintains accurate records of cleaning and sanitation activities, including documentation of cleaning agents used.

- Records and reports any incidents of contamination or sanitation concerns to management.

- Completes and maintains sanitation logs and other required documentation.

4. Training and Supervision

Contributes to the training and supervision of other employees on proper cleaning and sanitation practices.

- Shares knowledge and experience with new hires and less experienced employees.

- Supervises and monitors the work of other sanitizers, ensuring they follow established procedures.

Interview Tips

Prior to the Interview:

1. Research the Company and Position

Learn about the company’s products, services, culture, and industry. This demonstrates your interest and preparation.

2. Practice Answering Common Interview Questions

Prepare for questions related to your experience, skills, and understanding of the job requirements.

Example Outline:

- Tell me about your experience in cleaning and sanitizing production environments.

- Describe your understanding of sanitation regulations and best practices.

- How do you monitor and ensure the effectiveness of your cleaning and sanitation procedures?

3. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the position.

Example Questions:

- What are the company’s specific sanitization standards and requirements?

- What are the opportunities for professional development and advancement?

- How does the company prioritize safety and quality in its production processes?

4. Be Professional and Enthusiastic

Dress appropriately, arrive on time, and maintain a positive and respectful demeanor.

5. Highlight Your Skills and Experience

Demonstrate your abilities in cleaning and sanitizing, monitoring and inspection, documentation and reporting, and training and supervision.

6. Emphasize Your Attention to Detail and Quality

Production sanitizing requires meticulous attention to detail and a commitment to maintaining high standards of cleanliness.

After the Interview:7. Follow Up

Send a thank-you note to the interviewer and reiterate your interest in the position.

8. Seek Feedback

If you are not offered the job, ask for feedback on your interview performance to improve your future interviews.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Sanitizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!