Are you gearing up for an interview for a Wafer Cleaner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wafer Cleaner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

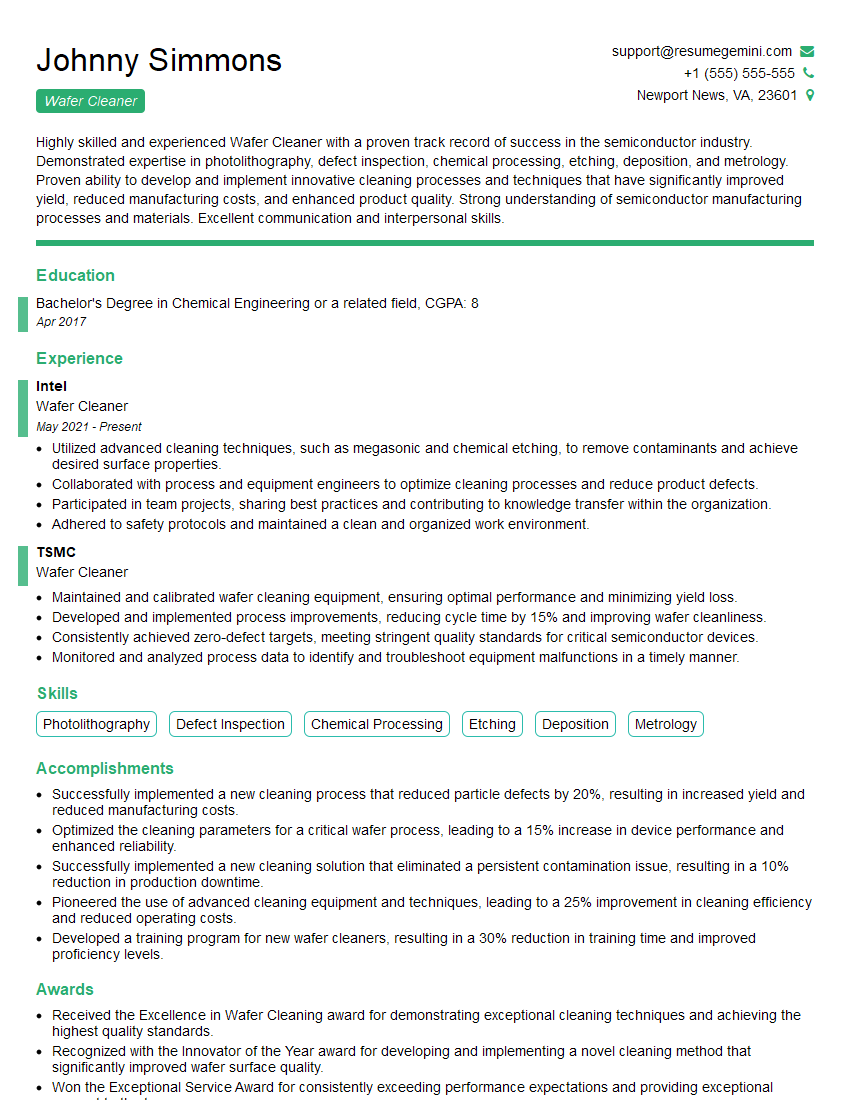

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Cleaner

1. What are the different types of wafer cleaning methods?

- RCA clean: This is a standard cleaning method that uses a series of three chemicals to remove organic and inorganic contaminants.

- SC-1 clean: This is a less aggressive clean than the RCA clean, and it is often used to remove organic contaminants.

- SC-2 clean: This is a more aggressive clean than the SC-1 clean, and it is used to remove inorganic contaminants.

- Plasma clean: This is a dry cleaning method that uses a plasma to remove organic and inorganic contaminants.

- UV/ozone clean: This is a dry cleaning method that uses UV light and ozone to remove organic contaminants.

2. What are the key parameters that need to be controlled during wafer cleaning?

Control of Chemical Concentration

- The concentration of the cleaning chemicals must be carefully controlled to ensure that the wafers are properly cleaned without being damaged.

- The concentration of the chemicals can affect the removal rate of contaminants, the surface roughness of the wafers, and the corrosion of the wafers.

Control of Temperature

- The temperature of the cleaning chemicals must also be carefully controlled to ensure that the wafers are properly cleaned without being damaged.

- The temperature of the chemicals can affect the removal rate of contaminants, the surface roughness of the wafers, and the corrosion of the wafers.

Control of Time

- The time that the wafers are exposed to the cleaning chemicals must also be carefully controlled to ensure that the wafers are properly cleaned without being damaged.

- The time that the wafers are exposed to the chemicals can affect the removal rate of contaminants, the surface roughness of the wafers, and the corrosion of the wafers.

3. What are the common defects that can occur during wafer cleaning?

- Scratches: Scratches can be caused by mishandling the wafers, using abrasive cleaning materials, or using excessive force during cleaning.

- Particles: Particles can be introduced into the wafers during cleaning by the cleaning chemicals, the cleaning equipment, or the cleanroom environment.

- Stains: Stains can be caused by the deposition of contaminants on the wafers during cleaning.

- Corrosion: Corrosion can be caused by the exposure of the wafers to corrosive chemicals or by the formation of an oxide layer on the wafers.

4. What are the safety precautions that need to be taken when handling wafer cleaning chemicals?

- Wear appropriate personal protective equipment (PPE), such as gloves, a lab coat, and safety glasses.

- Handle the chemicals in a well-ventilated area.

- Do not ingest or inhale the chemicals.

- Do not mix the chemicals with other chemicals unless specifically instructed to do so.

- Dispose of the chemicals properly according to local regulations.

5. What are the maintenance procedures that need to be performed on wafer cleaning equipment?

- Regularly inspect the equipment for any signs of damage or wear.

- Clean the equipment regularly to remove any contaminants that may have accumulated.

- Calibrate the equipment regularly to ensure that it is operating properly.

- Replace any worn or damaged parts as necessary.

6. What is the role of automation in wafer cleaning?

- Automation can play a significant role in wafer cleaning by improving the efficiency, accuracy, and consistency of the process.

- Automated wafer cleaning systems can perform a variety of tasks, such as loading and unloading wafers, dispensing cleaning chemicals, and rinsing and drying wafers.

- Automation can help to reduce the risk of human error and contamination, and it can also improve the throughput of the wafer cleaning process.

7. What are the latest trends in wafer cleaning technology?

- The use of new cleaning chemistries that are more environmentally friendly and less corrosive.

- The development of new cleaning equipment that is more efficient and reliable.

- The integration of automation into wafer cleaning processes to improve efficiency and accuracy.

8. What are the challenges facing the wafer cleaning industry?

- The need to clean wafers with increasingly smaller features.

- The need to clean wafers with new materials.

- The need to reduce the environmental impact of wafer cleaning.

9. What are your strengths and weaknesses as a wafer cleaner?

- Strengths: I have a strong understanding of the wafer cleaning process, and I am proficient in the use of a variety of wafer cleaning equipment.

- Weaknesses: I am still relatively new to the semiconductor industry, and I do not have as much experience as some other candidates.

10. Why are you interested in this position?

- I am interested in this position because I am passionate about the semiconductor industry, and I believe that wafer cleaning is a critical part of the manufacturing process.

- I am confident that I have the skills and experience necessary to be successful in this role, and I am eager to learn more about the company and the position.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Cleaner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Cleaner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wafer Cleaner is an essential role in the semiconductor industry, responsible for cleaning and preparing silicon wafers for use in microchip manufacturing. Their duties include:

1. Wafer Inspection and Preparation

Inspecting incoming wafers for defects, particles, and contamination.

- Identifying and removing any contamination or defects using appropriate cleaning methods.

2. Cleaning Process Management

Operating and maintaining wafer cleaning equipment, including wet benches and dry etching tools.

- Monitoring and controlling process parameters such as temperature, chemical concentration, and cycle time.

- Ensuring that cleaning processes meet quality standards and specifications.

3. Process Development and Improvement

Collaborating with engineers to develop and improve wafer cleaning processes.

- Evaluating new cleaning technologies and materials.

- Identifying and addressing sources of contamination and defects.

4. Equipment Maintenance and Troubleshooting

Maintaining and calibrating wafer cleaning equipment to ensure optimal performance.

- Troubleshooting and resolving equipment malfunctions or issues.

- Performing preventive maintenance and repairs as needed.

Interview Tips

Preparing for a Wafer Cleaner interview requires a comprehensive understanding of the role and industry. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s background, values, and products to demonstrate your interest and knowledge.

- Specifically review the job description to identify the core responsibilities and requirements.

2. Highlight Your Technical Skills

Emphasize your proficiency in wafer cleaning techniques, equipment operation, and process control.

- Quantify your accomplishments with specific examples and metrics.

- Discuss your experience in troubleshooting and resolving equipment issues.

3. Demonstrate Process Understanding

Explain your understanding of semiconductor manufacturing processes and how wafer cleaning contributes to overall yield.

- Describe your knowledge of contamination control and defect reduction.

4. Prepare for Industry-Specific Questions

Expect questions about specific cleaning methods, such as RCA cleaning or SC-1/SC-2 processes.

- Research the latest trends and innovations in wafer cleaning technology.

5. Show Your Commitment to Quality

Emphasize your attention to detail, meticulousness, and commitment to delivering high-quality products.

- Describe your quality control procedures and how you ensure adherence to specifications.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wafer Cleaner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.