Are you gearing up for a career in Tumbling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tumbling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

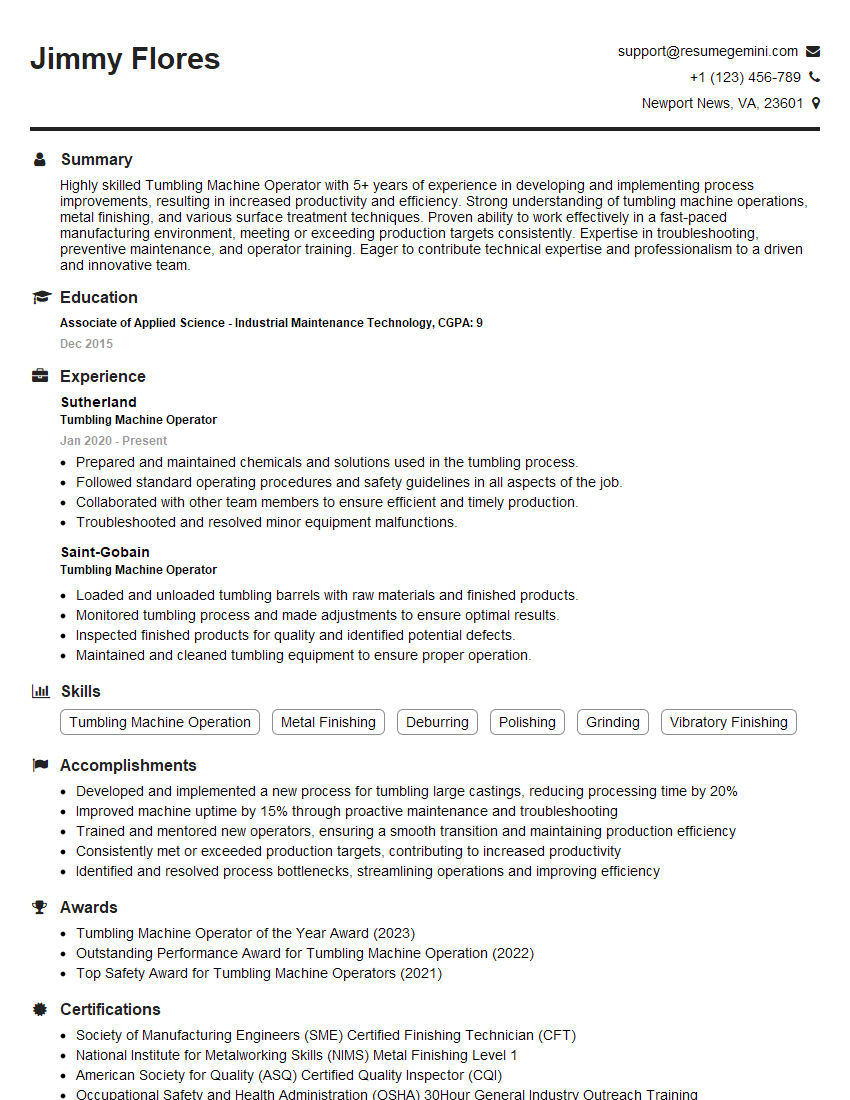

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tumbling Machine Operator

1. Explain the process of how tumbling machines are used in the manufacturing process?

Tumbling machines are used in the manufacturing process to deburr, polish, or clean metal parts. The process involves placing the parts in a rotating barrel filled with abrasive media like ceramic chips or plastic beads. As the barrel rotates, the media rubs against the parts, removing burrs, smoothing surfaces, or cleaning away contaminants.

2. What safety precautions should be taken when operating tumbling machines?

Proper ventilation

- Ensure adequate ventilation in the work area to remove dust and fumes generated during tumbling.

Proper PPE

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to minimize exposure to abrasives and chemicals.

Machine guarding

- Ensure that the tumbling machine has proper guarding in place to prevent contact with rotating parts and moving media.

Training

- Receive proper training on the specific tumbling machine being used, including its operating procedures, maintenance, and safety features.

3. How do you determine the appropriate media and cycle time for a specific tumbling application?

Determining the appropriate media and cycle time for a specific tumbling application depends on several factors, including:

- Part material and surface finish requirements

- Type of media (ceramic chips, plastic beads, etc.)

- Size and shape of parts

- Desired level of deburring, polishing, or cleaning

- Experience and recommendations from manufacturers or industry experts

4. What are the common maintenance tasks required for tumbling machines?

Regular maintenance tasks for tumbling machines include:

- Cleaning the barrel and media to remove debris and abrasives

- Inspecting and replacing worn or damaged belts or bearings

- Lubricating moving parts according to the manufacturer’s recommendations

- Calibrating the machine to ensure proper rotation speed and cycle times

5. How do you troubleshoot common problems with tumbling machines, such as excessive noise or uneven finishing?

- Excessive noise: Check for loose or damaged bearings, unbalanced loads, or worn-out media.

- Uneven finishing: Inspect the media for wear or contamination, adjust the cycle time or rotation speed, or consider using a different media type.

6. What is the importance of quality control when operating tumbling machines?

Quality control is crucial when operating tumbling machines to ensure that parts meet the required specifications. This involves:

- Inspecting parts before and after tumbling to identify any defects or inconsistencies

- Monitoring the tumbling process to ensure that the correct parameters (cycle time, rotation speed, media type) are being used

- Maintaining records of tumbling operations for traceability and quality assurance

7. How do you improve the efficiency and productivity of tumbling operations?

Improving efficiency and productivity of tumbling operations involves:

- Optimizing media selection and cycle times

- Automating the loading and unloading of parts

- Using advanced tumbling machines with features like variable speed control and programmable cycles

- Implementing lean manufacturing principles to reduce waste and improve flow

8. What are the different types of tumbling machines available, and what are their specific applications?

- Rotary barrel tumbling machines: Used for general-purpose deburring, polishing, and cleaning of small parts

- Vibratory tumbling machines: Suitable for delicate parts or applications requiring a gentler touch

- Centrifugal barrel tumbling machines: Used for high-volume deburring and finishing of large parts

9. How do you ensure that tumbling machines are operating at peak performance?

To ensure peak performance of tumbling machines, it is important to:

- Perform regular maintenance and calibration

- Use the correct media and cycle parameters for the specific application

- Monitor the tumbling process and make adjustments as needed

- Keep the work area clean and free of debris

10. What are the emerging trends and advancements in the field of tumbling technology?

- Automation and robotics: Increasing use of automated loading and unloading systems, as well as robotic arms for media handling

- Advanced process control: Real-time monitoring and control of tumbling parameters to optimize efficiency and quality

- Environmentally friendly media: Development of sustainable and biodegradable media materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tumbling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tumbling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tumbling Machine Operator is responsible for operating and monitoring tumbling machines used in various industrial processes, such as metal finishing, deburring, and surface preparation. The key job responsibilities include:

1. Machine Operation

Loading and unloading tumbling barrels with workpieces

- Setting and adjusting machine parameters, such as speed, cycle time, and media type

- Monitoring machine operation to ensure proper functioning

2. Media Management

Selecting and preparing tumbling media, such as abrasives, polishing compounds, and detergents

- Monitoring media condition and replacing or replenishing as needed

- Cleaning and drying media to maintain its effectiveness

3. Quality Control

Inspecting workpieces after tumbling to ensure they meet specifications

- Identifying and segregating defective parts

- Maintaining records of machine settings and quality control data

4. Machine Maintenance

Performing routine maintenance and repairs on tumbling machines

- Lubricating and adjusting moving parts

- Troubleshooting and resolving machine malfunctions

Interview Tips

To ace an interview for a Tumbling Machine Operator position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are a few interview tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company website and read industry publications.

- Research the specific job requirements and responsibilities.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating tumbling machines and managing media.

- Quantify your accomplishments and provide specific examples of your work.

- Showcase your knowledge of different tumbling processes and media types.

3. Demonstrate Attention to Detail

Tumbling Machine Operators must pay close attention to detail to ensure the quality of the finished product.

- Highlight your ability to follow instructions and maintain accurate records.

- Emphasize your experience in identifying and segregating defective parts.

4. Prepare for Technical Questions

Be prepared to answer questions about tumbling machine operation, media management, and quality control procedures.

- Review the different types of tumbling machines and their applications.

- Research the principles of tumbling and the factors that affect the process.

5. Show Enthusiasm and Curiosity

Express your passion for working with machinery and your eagerness to learn new things.

- Ask questions about the company’s processes and the latest industry advancements.

- Show your willingness to take on additional responsibilities and challenges.

Next Step:

Now that you’re armed with the knowledge of Tumbling Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tumbling Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini