Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Acid Etch Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

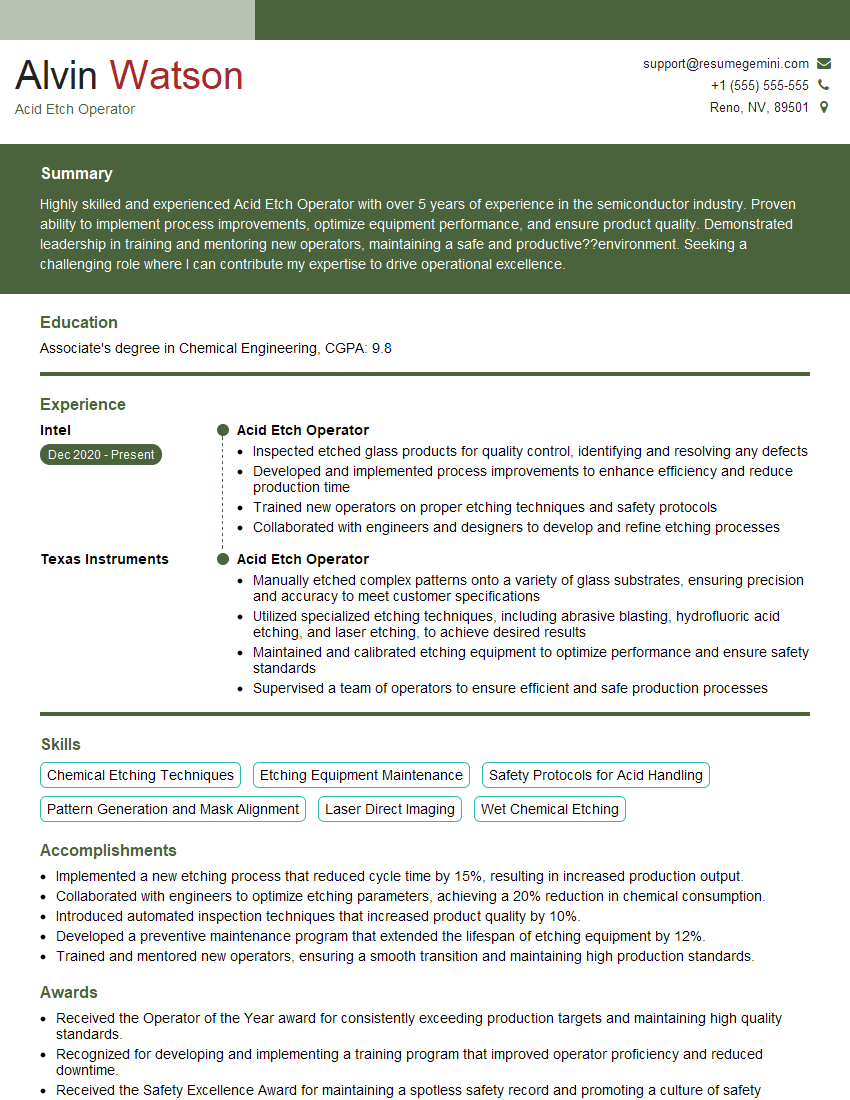

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acid Etch Operator

1. What are the different types of acid etching techniques?

There are two main types of acid etching techniques:

- Wet etching: This technique uses a liquid acid to etch the surface of the material. The acid is applied to the surface of the material and allowed to react for a period of time. The acid will dissolve the material, creating a pattern in the surface.

- Dry etching: This technique uses a gas plasma to etch the surface of the material. The gas plasma is created by passing an electric current through a gas. The gas plasma will react with the surface of the material, creating a pattern in the surface.

2. What are the different types of acids used in acid etching?

Etching Agents

- Hydrochloric acid (HCl)

- Nitric acid (HNO3)

- Sulfuric acid (H2SO4)

Pickling Agents

- Phosphoric acid (H3PO4)

- Citric acid (C6H8O7)

3. What are the different factors that affect the rate of acid etching?

The rate of acid etching is affected by a number of factors, including:

- The type of acid used

- The concentration of the acid

- The temperature of the acid

- The duration of the etching process

- The type of material being etched

4. How do you control the depth of the etch?

The depth of the etch is controlled by a number of factors, including:

- The concentration of the acid

- The temperature of the acid

- The duration of the etching process

- The type of material being etched

5. What are the safety precautions that must be taken when working with acid etching?

Acid etching is a hazardous process, and it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Handle acids with care and avoid contact with skin and eyes.

- Dispose of acids properly.

6. What is the purpose of acid etching in the manufacturing process?

Acid etching is used in a variety of manufacturing processes, including:

- Creating patterns in metal surfaces

- Removing burrs and other imperfections from metal surfaces

- Cleaning metal surfaces

- Preparing metal surfaces for painting or plating

7. What are the different types of equipment used in acid etching?

The following types of equipment are used in acid etching:

- Acid baths

- Spray etchers

- Plasma etchers

- Laser etchers

8. What are the different types of materials that can be acid etched?

Acid etching can be used on a variety of materials, including:

- Metals

- Glass

- Ceramics

- Plastics

9. What are the advantages and disadvantages of acid etching?

Advantages

- Acid etching is a relatively simple and inexpensive process.

- It can be used to create a wide variety of patterns and designs.

- It can be used on a variety of materials.

Disadvantages

- Acid etching can be hazardous if not done properly.

- It can damage the surface of the material being etched.

- It can create sharp edges that can be dangerous.

10. What are some tips for successful acid etching?

- Use the correct type of acid for the material you are etching.

- Use the correct concentration of acid.

- Use the correct temperature for the acid.

- Etch for the correct amount of time.

- Rinse the etched surface thoroughly with water.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acid Etch Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acid Etch Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Acid Etch Operators are responsible for preparing and etching metal surfaces to create a smooth, clean finish. They use a variety of chemicals and equipment to complete their tasks, including acids, bases, and solvents. Acid Etch Operators must have a strong understanding of chemistry and safety procedures, as well as the ability to work independently and follow instructions precisely.

1. Prepare metal surfaces for etching

Before etching metal surfaces, Acid Etch Operators must first prepare them by cleaning and degreasing them. This ensures that the etching process will be effective and that the final product will be of high quality.

- Clean metal surfaces with solvents

- Degrease metal surfaces with chemicals

- Inspect metal surfaces for defects

2. Etch metal surfaces

Once the metal surfaces have been prepared, Acid Etch Operators use a variety of chemicals to etch them. Etching is a process that removes material from the surface of the metal, creating a smooth, clean finish. The type of chemical used for etching depends on the type of metal being etched.

- Apply etching chemicals to metal surfaces

- Control the etching process to achieve the desired results

- Rinse metal surfaces with water

3. Neutralize metal surfaces

After etching metal surfaces, Acid Etch Operators must neutralize them to remove any remaining chemicals. This ensures that the metal surfaces are safe to handle and that they will not corrode.

- Apply neutralizing chemicals to metal surfaces

- Rinse metal surfaces with water

- Dry metal surfaces

4. Inspect metal surfaces

Once the metal surfaces have been etched and neutralized, Acid Etch Operators must inspect them to ensure that they meet the required specifications. This includes checking for defects, such as scratches or pits.

- Visually inspect metal surfaces

- Measure metal surfaces to ensure that they meet specifications

- Identify and correct any defects

Interview Tips

Preparing for an Acid Etch Operator interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few interview tips and hacks to help you ace your next interview:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can research the company’s website, read articles about the company, and talk to people who work there.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself

- Explain why you are interested in the position

- Highlight your skills and experience

3. Be prepared to talk about your experience

In an interview, you will likely be asked about your experience and qualifications. Be prepared to talk about your work history, your skills, and your accomplishments. You can use the STAR method to answer these questions. The STAR method is a storytelling technique that stands for Situation, Task, Action, and Result.

- Describe a situation where you faced a challenge

- Explain the task that you were responsible for

- Describe the actions that you took

- Share the results of your efforts

4. Ask questions

At the end of the interview, you should ask the interviewer questions about the position and the company. This shows that you are interested in the job and that you are taking the interview seriously. You can ask questions about the company’s culture, the work environment, and the opportunities for advancement.

- Ask about the company’s culture

- Ask about the work environment

- Ask about the opportunities for advancement

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Acid Etch Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Acid Etch Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.