Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Engraving Patternmaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

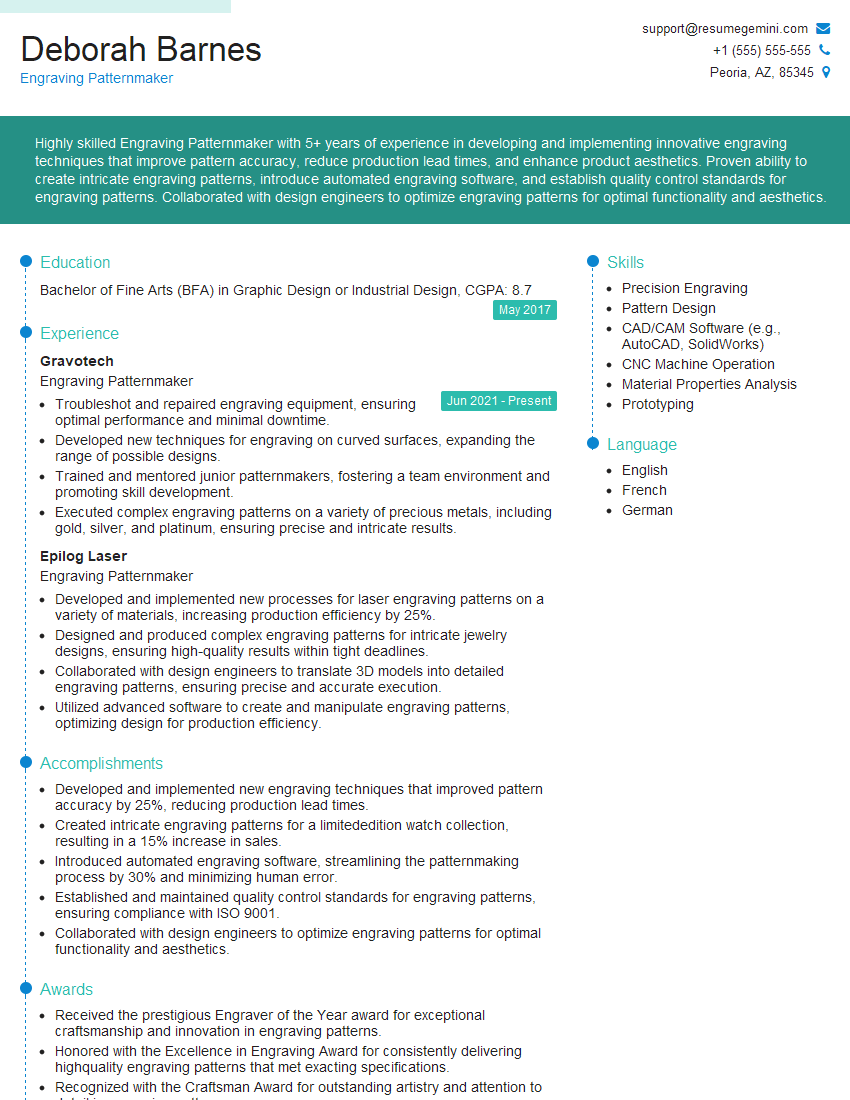

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engraving Patternmaker

1. What types of engraving machines are you proficient in operating?

- XYZ Cartesian coordinate engraving machines

- Rotary engraving machines

- 5-Axis CNC engraving machines

2. Explain the process of creating an engraving pattern from a 3D model.

Creating the Toolpath

- Import the 3D model into CAD software.

- Generate the toolpath using the engraving software.

Generating the G-code

- Export the toolpath to G-code.

- Run the G-code on the engraving machine.

3. Describe the different materials you have experience engraving, and the techniques you use for each.

- Metals: Rotary engraving, laser engraving, chemical etching

- Plastics: Laser engraving, CNC engraving, waterjet cutting

- Wood: CNC engraving, laser engraving, pyrography

- Glass: Laser engraving, sandblasting, chemical etching

4. Explain the process of calibrating an engraving machine.

- Inspect the machine for mechanical errors.

- Level the work surface.

- Calibrate the axes using a precision reference.

- Test the calibration with a known pattern.

5. What troubleshooting steps do you take when an engraving job fails?

- Check the file path and G-code for errors.

- Inspect the machine for mechanical or electrical issues.

- Clean the engraving head and substrate.

- Adjust the engraving parameters (feed rate, spindle speed).

6. What is the role of a coordinate measuring machine (CMM) in engraving patternmaking?

- Inspecting the accuracy of engraved patterns.

- Measuring the dimensions and features of engraved parts.

- Creating 3D scans of engraved surfaces.

7. Explain the different types of cutting tools used in engraving, and how they can affect the final product.

- Ball nose end mills: Create 3D engravings with smooth contours.

- Flat end mills: Create 2D engravings with sharp edges.

- V-shaped end mills: Create V-shaped engravings for text and logos.

- Laser engraving heads: Create precise and detailed engravings using laser technology.

8. Describe the importance of material hardness in the engraving process.

- Harder materials require stronger cutting tools and higher power settings.

- Softer materials can be engraved more easily, but may require slower feed rates to avoid tearing.

- The hardness of the material determines the depth and detail of the engraving.

9. Explain the principles of laser engraving, and how it differs from other engraving methods.

- Laser engraving: Uses a focused laser beam to vaporize material from the surface.

- Rotary engraving: Uses a sharp tool to cut into the material.

- Chemical etching: Uses a corrosive chemical to dissolve material from the surface.

- Waterjet cutting: Uses a high-pressure stream of water to cut through the material.

10. Describe a complex engraving project you have completed, and the challenges you faced.

- Explain the project requirements and objectives.

- Discuss the technical challenges you encountered.

- Describe how you overcame these challenges.

- Highlight the results and customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engraving Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engraving Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Engraving Patternmakers are responsible for creating patterns for engraved products. Their work requires precision and attention to detail, as they need to ensure that the patterns are accurate and that the final product will be of high quality.

1. Designing patterns

Engraving Patternmakers typically start by creating a design for the pattern. This design will be based on the customer’s specifications, and it will need to take into account the size, shape, and complexity of the product.

- Creating sketches and drawings of patterns

- Using computer-aided design (CAD) software to create digital patterns

2. Transferring patterns to metal

Once the pattern has been designed, it needs to be transferred to metal. This can be done using a variety of methods, including hand engraving, photoengraving, and laser engraving.

- Hand engraving patterns using tools such as chisels and gravers

- Using photoengraving machines to transfer patterns to metal using light-sensitive chemicals

- Using laser engraving machines to engrave patterns using a high-powered laser

3. Inspecting and finishing patterns

Once the pattern has been transferred to metal, it needs to be inspected to ensure that it is accurate and that there are no defects. The pattern may also need to be finished, such as by polishing or plating.

- Inspecting patterns for accuracy and defects

- Polishing patterns to remove burrs and imperfections

- Plating patterns to protect them from corrosion

4. Maintaining tools and equipment

Engraving Patternmakers need to maintain their tools and equipment in good working order. This includes cleaning and lubricating tools, and replacing worn or damaged parts.

- Cleaning and lubricating engraving tools

- Replacing worn or damaged engraving tools

- Maintaining and calibrating engraving machines

Interview Tips

Preparing for an interview for an Engraving Patternmaker position can be daunting, but there are some things you can do to improve your chances of success.

1. Research the company and the position

The more you know about the company and the position, the better prepared you will be to answer questions and demonstrate your qualifications. Make sure you visit the company website, read the job description carefully, and research the industry.

- Research the company’s history, products, and services

- Read the job description carefully and identify the key requirements

- Research the engraving industry and its trends

2. Practice answering common interview questions

There are some common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why should we hire you?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Practice answering questions about your experience and skills

- Practice answering questions about your motivations and goals

- Practice answering questions about your knowledge of the industry

3. Prepare questions to ask the interviewer

Asking questions at the end of the interview shows that you are interested in the position and that you are taking the interview seriously. Prepare a few questions in advance, such as “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”.

- Prepare questions about the company’s culture and values

- Prepare questions about the position and its responsibilities

- Prepare questions about the company’s future plans

4. Dress professionally and arrive on time

First impressions matter, so make sure you dress appropriately for the interview and arrive on time. This shows that you respect the interviewer’s time and that you are taking the interview seriously.

- Wear a suit or business casual attire

- Arrive 10-15 minutes early for the interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Engraving Patternmaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Engraving Patternmaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.