Are you gearing up for an interview for a Rubber Engraver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rubber Engraver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

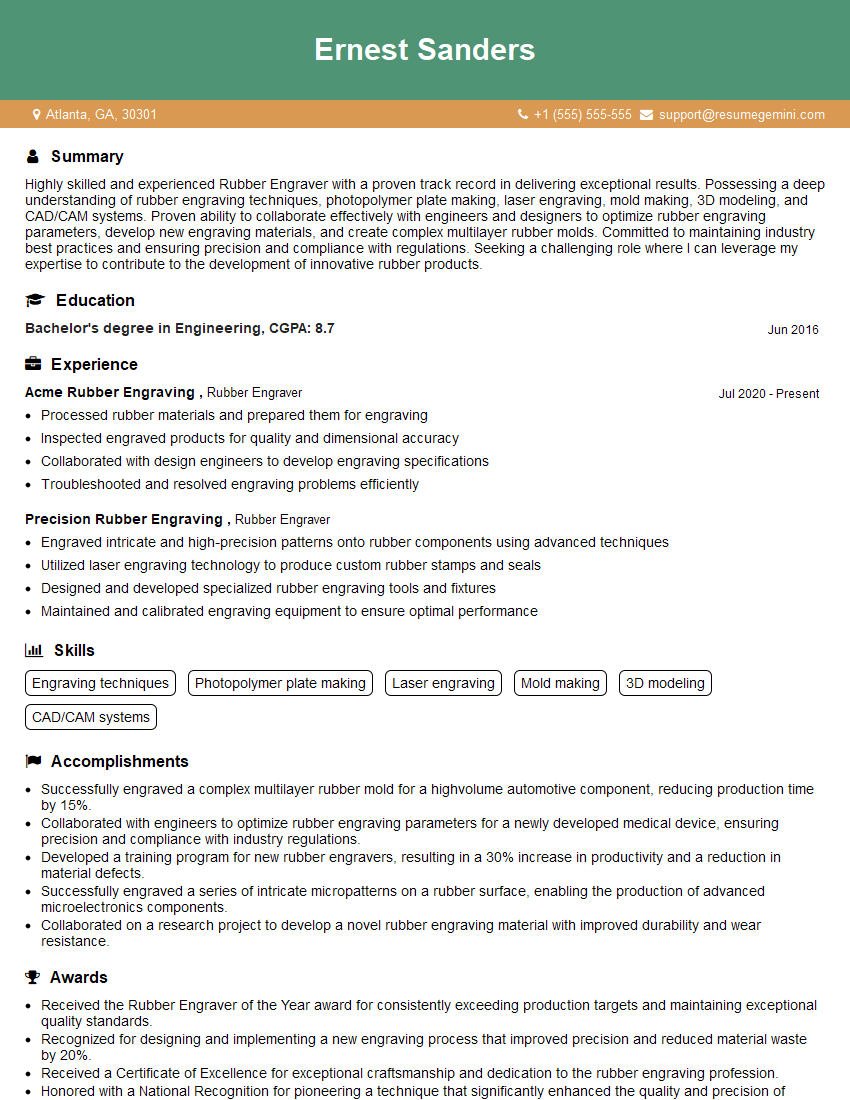

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Engraver

1. Explain the different types of rubber used for engraving?

There are various types of rubber used for engraving, each with unique properties and applications. Here are the most common types:

- Natural rubber: Derived from the latex of rubber trees, natural rubber is known for its elasticity, durability, and resilience.

- Synthetic rubber: Created artificially, synthetic rubber offers higher resistance to chemicals and temperature extremes compared to natural rubber.

- Elastomeric rubber: A blend of natural and synthetic rubber, elastomeric rubber combines the advantages of both types, providing excellent flexibility and resistance to wear and tear.

- Silicone rubber: Known for its high temperature resistance, flexibility, and chemical inertness, silicone rubber is often used for specialized applications.

2. Describe the process of laser engraving on rubber?

Laser Engraving Setup

- Choose the appropriate laser system and wavelength based on the type of rubber.

- Secure the rubber material on the laser engraving machine.

Laser Engraving Operation

- Import the desired design or artwork into the laser engraving software.

- Calibrate the laser settings, including power, speed, and focus, to ensure optimal engraving results.

- Initiate the laser engraving process, guiding the laser beam over the rubber surface according to the design.

3. What are the key factors to consider when selecting cutting tools for rubber engraving?

When selecting cutting tools for rubber engraving, several key factors need to be considered to ensure precision and efficiency:

- Material type: Different types of rubber require specific cutting tools designed for their specific properties.

- Engraving depth: The required engraving depth influences the choice of cutting tool’s size and shape.

- Accuracy and precision: High-quality cutting tools provide greater accuracy and precision in engraving.

- Tool life: Consider the durability and lifespan of the cutting tool to minimize downtime and maintenance costs.

- Cost: Evaluate the cost of cutting tools in relation to their performance and longevity.

4. How do you ensure the accuracy and precision of engraved rubber products?

Ensuring accuracy and precision in engraved rubber products requires meticulous attention to detail throughout the engraving process:

- Precise design: Create a detailed and accurate design or artwork for engraving.

- Calibration: Calibrate the engraving machine regularly to maintain optimal settings.

- Material handling: Handle the rubber material carefully to avoid any distortion or damage.

- Quality control: Implement a rigorous quality control process to inspect engraved products for accuracy and precision.

5. What are the common challenges in rubber engraving and how do you overcome them?

Rubber engraving presents several challenges that require specific solutions:

- Rubber flexibility: Overcome the challenge of rubber’s flexibility by using appropriate engraving techniques and securing the material securely.

- Tear resistance: Address the tear-resistant nature of rubber by employing sharp cutting tools and minimizing excessive force during engraving.

- Material distortion: Prevent material distortion by using a stable engraving platform and minimizing heat buildup during the engraving process.

- Precision engraving: Achieve precise engraving by using high-quality cutting tools, calibrating the engraving machine, and employing a steady hand.

6. How do you maintain and clean rubber engraving equipment?

Proper maintenance and cleaning of rubber engraving equipment are crucial for its longevity and optimal performance:

- Regular cleaning: Remove rubber debris and dust from the engraving machine regularly to prevent clogging and malfunction.

- Lubrication: Lubricate moving parts of the machine as per the manufacturer’s instructions to ensure smooth operation.

- Calibration: Regularly calibrate the engraving machine to maintain accuracy and precision.

- Environmental control: Ensure a clean and dust-free work environment to minimize contamination of the engraving equipment.

7. Describe the safety protocols you follow when operating a rubber engraving machine?

Safety is paramount when operating a rubber engraving machine:

- Personal protective equipment: Wear appropriate personal protective equipment, including safety glasses, gloves, and a mask.

- Machine guarding: Ensure that the engraving machine has proper guarding to prevent access to moving parts.

- Electrical safety: Verify that the machine is properly grounded and electrical connections are secure.

- Ventilation: Provide adequate ventilation to remove fumes and dust generated during engraving.

- Training: Receive thorough training on the safe operation of the engraving machine.

8. How do you stay updated with the latest advancements in rubber engraving technology?

To stay abreast of the latest advancements in rubber engraving technology:

- Industry events: Attend industry conferences, workshops, and exhibitions to learn about new technologies and innovations.

- Online resources: Utilize online platforms, such as industry-specific websites and forums, to access technical articles, research papers, and product updates.

- Training programs: Participate in training programs offered by manufacturers or industry organizations to gain knowledge about new equipment and techniques.

- Collaboration: Engage with other professionals in the field to share knowledge and exchange ideas about the latest advancements.

9. Provide an example of a complex rubber engraving project you have successfully completed?

Describe a challenging rubber engraving project you undertook, highlighting the following aspects:

- Project complexity: Explain the intricate details or unique requirements of the project.

- Technical approach: Outline the specific techniques and strategies employed to achieve the desired results.

- Problem-solving: Describe any obstacles encountered and how you overcame them.

- Quality control: Explain how you ensured the accuracy and precision of the engraved product.

10. How do you handle deadlines and prioritize tasks when working on multiple rubber engraving projects concurrently?

Explain your approach to managing multiple projects simultaneously:

- Project prioritization: Describe how you assess the importance and urgency of each project.

- Time management: Outline the techniques you use to allocate time effectively and meet deadlines.

- Communication: Explain how you communicate with clients and stakeholders to manage expectations and keep them informed of progress.

- Delegation: Describe your approach to delegating tasks when necessary to ensure timely project completion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber engravers are highly skilled professionals who create designs and patterns on rubber stamps and other rubber products. Their work is used in a variety of industries, including printing, packaging, and manufacturing.

1. Design and Create Rubber Stamps

Rubber engravers use a variety of tools and techniques to create custom rubber stamps. They start by designing the stamp, which may involve creating a digital image or drawing a sketch. Once the design is complete, the engraver will use a carving tool to create the design in the rubber.

- Meet with clients to discuss their needs and design ideas.

- Create digital or hand-drawn designs for rubber stamps.

- Use carving tools to create designs in the rubber.

2. Produce Other Rubber Products

In addition to rubber stamps, rubber engravers also produce a variety of other rubber products, such as gaskets, seals, and bumpers. These products are used in a variety of applications, including automotive, aerospace, and medical.

- Create designs for rubber gaskets, seals, and bumpers.

- Use carving tools to create designs in the rubber.

- Inspect finished products to ensure quality.

3. Maintain Equipment

Rubber engravers are responsible for maintaining their own equipment. This includes cleaning and lubricating tools, as well as replacing worn parts.

- Clean and lubricate tools.

- Replace worn parts.

- Calibrate equipment.

4. Safety

Rubber engravers must follow all safety regulations. This includes wearing appropriate safety gear and using tools properly.

- Wear appropriate safety gear.

- Use tools properly.

- Follow all safety regulations.

Interview Tips

Interviewing for a rubber engraver position can be competitive. Here are a few tips to help you ace the interview:

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website.

- Read online reviews of the company.

- Talk to people who work at the company.

- Review the job description carefully.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance. This will help you to feel more confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Prepare Questions to Ask the Interviewer

At the end of the interview, you will be given an opportunity to ask the interviewer questions. This is a great opportunity to learn more about the company and the position. It is also a chance to show the interviewer that you are interested and engaged.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement?

- What is the next step in the interview process?

4. Dress Professionally and Arrive on Time

It is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect their time. It is also important to arrive on time for your interview. Being late can make a bad impression on the interviewer.

- Wear a suit or business casual attire.

- Be well-groomed.

- Arrive on time for your interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rubber Engraver role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.