Are you gearing up for an interview for a Wax Engraver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wax Engraver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

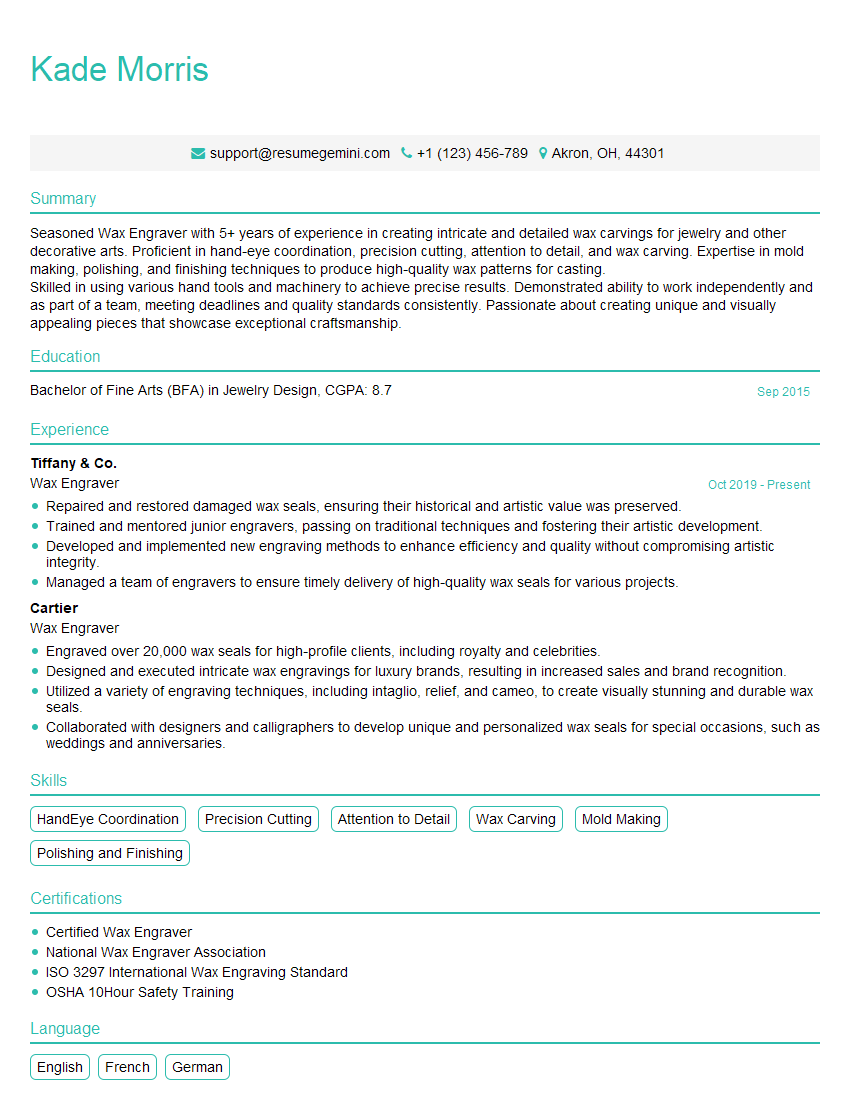

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wax Engraver

1. What are the different techniques used in wax engraving?

- Scraper engraving: Using a sharp tool to scrape away wax, creating a recessed design.

- Burin engraving: Using a burin tool to carve into the wax, tạo ra đường nét tinh xảo.

- Comb engraving: Using a comb-like tool to create parallel lines or patterns in the wax.

- Stippling engraving: Using a pointed tool to create dots or textures in the wax.

2. How do you prepare the wax for engraving?

Softening:

- Heat the wax to a malleable temperature.

- Control temperature to prevent the wax from melting or becoming too soft.

Smoothing:

- Use a polishing tool or scraper to smooth the wax surface.

- Remove any imperfections or irregularities.

3. What are the key factors to consider when designing a wax engraving?

- Purpose and intended use of the engraved piece.

- Level of detail and complexity required.

- Size and shape of the wax surface.

- Materials and tools available.

4. How do you transfer a design onto wax for engraving?

- Tracing: Using a pencil or stylus to transfer the design onto the wax.

- Carbon paper: Placing carbon paper between the design and the wax to create a transfer.

- Direct engraving: Freehand engraving without a transferred design.

5. What are the common types of wax used for engraving?

- Beeswax: Natural and versatile, good for fine details.

- Carnauba wax: Hard and durable, suitable for larger pieces.

- Synthetic wax: Engineered for specific properties, such as higher melting points or colors.

6. How do you maintain and clean wax engraving tools?

- Regular sharpening: Keep tools sharp to ensure precision.

- Cleaning: Remove wax residue from tools using solvents or brushes.

- Storage: Store tools in a dry place to prevent rust or damage.

7. What safety precautions should be taken when wax engraving?

- Sharp tools: Handle tools carefully to avoid cuts or punctures.

- Heat: Wear heat-resistant gloves when handling hot wax.

- Fumes: Ensure proper ventilation to avoid inhaling wax fumes.

8. How do you incorporate different textures and depths into a wax engraving?

- Varying tool pressure: Apply more or less pressure to create different depths.

- Multiple passes: Repeat engraving strokes to create deeper or more textured areas.

- Combination of techniques: Use different engraving techniques to achieve varying effects.

9. How do you restore or repair damaged wax engravings?

- Melting and re-engraving: Remove damaged areas, melt the wax, and re-engrave the design.

- Wax filling: Fill damaged areas with melted wax and blend it with the surrounding surface.

- Patina matching: Color or age the repaired areas to match the original patina.

10. What are some innovative or emerging techniques in wax engraving?

- Laser engraving: Using a laser to etch designs onto wax.

- 3D wax engraving: Creating three-dimensional models or sculptures using wax engraving.

- Digital design and engraving: Using computer-aided design and engraving machines for precision and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wax Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wax Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wax Engravers are skilled craftspeople who use a variety of tools and techniques to create intricate designs in wax. The key responsibilities of a Wax Engraver include:

1. Design and create wax engravings

Wax Engravers use their artistic skills to design and create wax engravings that are both beautiful and durable. They work with clients to develop ideas and then translate those ideas into detailed wax models.

- Interpret designs and specifications to create wax engravings that meet customer requirements.

- Use a variety of tools and techniques to engrave designs into wax.

- Ensure that the engravings are accurate and free of defects.

2. Prepare wax for engraving

Before beginning to engrave, Wax Engravers must prepare the wax by heating it and rolling it out into a thin sheet. They then use a variety of tools to smooth the surface of the wax and remove any imperfections.

- Prepare wax by heating and rolling it out into a thin sheet.

- Smooth the surface of the wax and remove any imperfections.

- Transfer designs onto the wax using a variety of methods, such as tracing, stamping, or carving.

3. Engrave designs into wax

Wax Engravers use a variety of tools and techniques to engrave designs into wax. These tools include burins, gouges, and knives. Wax Engravers must use precision and skill to create engravings that are both accurate and aesthetically pleasing.

- Use burins, gouges, and knives to engrave designs into wax.

- Use precision and skill to create engravings that are both accurate and aesthetically pleasing.

- Incorporate different textures and details into the engravings to create a unique and visually appealing design.

4. Finish and polish engravings

Once the engravings are complete, Wax Engravers must finish and polish them. This involves removing any burrs or rough edges and then applying a sealant to protect the engraving from damage.

- Remove any burrs or rough edges from the engravings.

- Apply a sealant to protect the engraving from damage.

- Package and ship the engravings to customers.

Interview Tips

Preparing for an interview can be stressful, but it’s also an opportunity to showcase your skills and experience. Here are a few tips to help you ace your interview for a Wax Engraver position:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you’re applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they’re looking for in a Wax Engraver.

- Visit the company’s website to learn about their history, mission, and products.

- Read online reviews of the company to get an idea of their culture and work environment.

- Search for news articles about the company to learn about their recent accomplishments and challenges.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

- Write down your answers to common interview questions and practice saying them out loud.

- Ask a friend or family member to conduct a mock interview with you.

- Record yourself answering interview questions and watch it back to identify areas for improvement.

3. Prepare questions to ask the interviewer

Asking questions at the end of an interview shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the role. Here are a few questions you might want to ask:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What is the company culture like?

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you’re serious about the position.

- Wear a suit or business casual attire to your interview.

- Arrive at the interview location 10-15 minutes early.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

5. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be honest and authentic in your answers.

- Make eye contact with the interviewer and speak clearly and confidently.

- Don’t be afraid to ask questions or share your ideas.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wax Engraver interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!