Feeling lost in a sea of interview questions? Landed that dream interview for Glass Bender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Glass Bender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

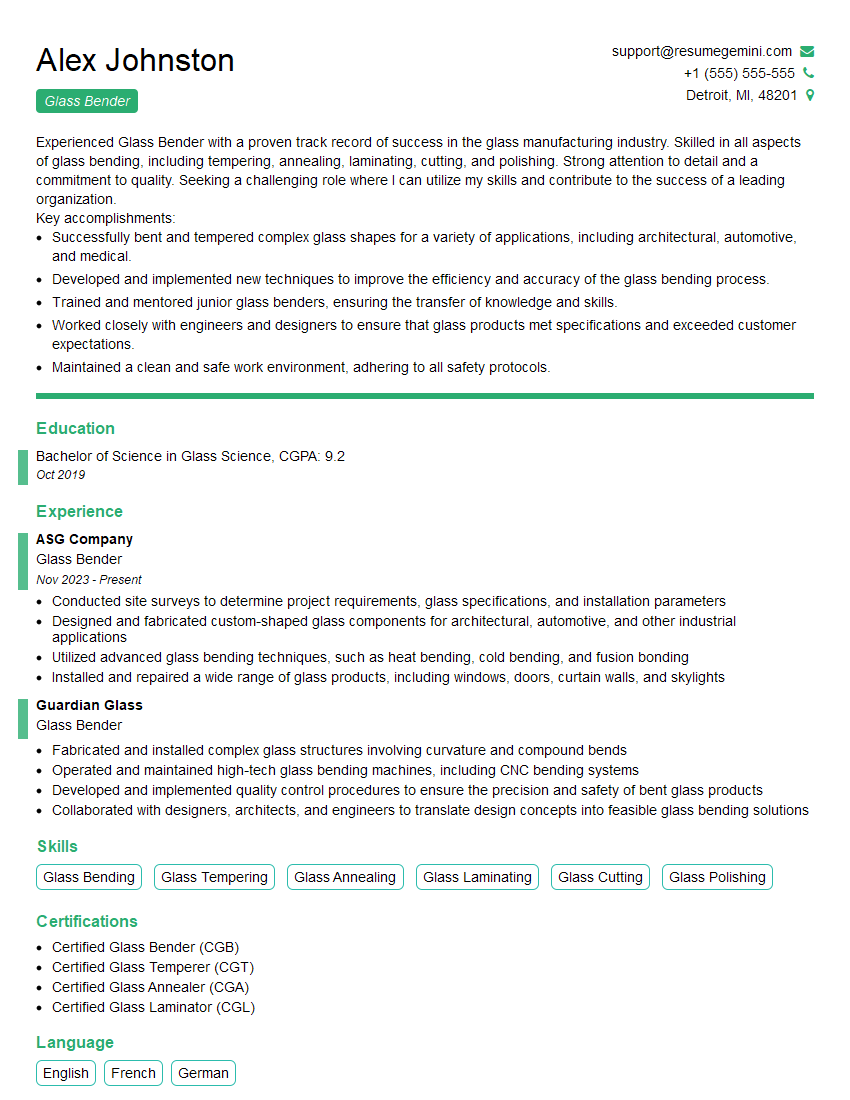

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Bender

1. What are the different types of glass bending techniques?

There are various glass bending techniques including:

- Hot bending: Involves heating the glass to its softening point and bending it using molds or forms.

- Cold bending: Uses a combination of mechanical force and heat to bend glass at temperatures below its softening point.

- Laminated glass bending: Bends multiple layers of glass bonded together with an interlayer material.

- Fusion bending: Melts the edges of glass sheets and fuses them together to create curved shapes.

- Kiln casting: Involves shaping molten glass in a kiln to create curved or 3D forms.

2. What factors influence the bendability of glass?

Glass Thickness

- Thicker glass is more difficult to bend without breaking.

Glass Composition

- Different glass compositions have varying degrees of flexibility.

- Borosilicate glass is more bendable than soda-lime glass.

Bending Temperature

- Glass should be heated to an appropriate temperature for bending without causing damage or distortion.

Bend Radius

- The minimum bend radius achievable depends on the glass type and bending method.

3. Describe the process of hot bending glass.

Hot bending involves:

- Heating the glass to its softening point (around 620-650°C for soda-lime glass).

- Placing the heated glass over a mold or form.

- Applying pressure to bend the glass into the desired shape.

- Cooling the glass slowly to relieve stress and prevent cracking.

4. What are the advantages and disadvantages of cold bending glass?

Advantages

- Can be done at lower temperatures, reducing energy costs.

- Suitable for thicker glass than hot bending.

- Produces less distortion and stress in the glass.

Disadvantages

- Requires specialized equipment and tooling.

- Slower process than hot bending.

- May not be suitable for complex shapes or tight bend radii.

5. What safety precautions should be taken when bending glass?

Safety precautions include:

- Wearing appropriate personal protective equipment (PPE) including gloves, eye protection, and a respirator.

- Handling glass carefully to avoid cuts or injuries.

- Ensuring the bending equipment is properly calibrated and maintained.

- Following all manufacturer’s instructions for the bending process.

- Allowing the glass to cool completely before handling to prevent thermal shock.

6. How do you determine the minimum bend radius for a given glass type and thickness?

The minimum bend radius depends on the glass type, thickness, and bending method. It can be calculated using formulas or obtained from glass manufacturers’ technical data sheets.

7. What are the different types of molds used in glass bending?

Molds used in glass bending include:

- Single-radius molds: Create bends with a single curvature.

- Compound molds: Create bends with multiple radii or complex shapes.

- Drape molds: Allow for free-form bending by supporting the glass without a rigid mold.

8. How do you inspect the quality of bent glass?

Quality inspection of bent glass involves:

- Visual inspection for cracks, distortions, or other defects.

- Dimensional measurements to ensure the bend radius and shape meet specifications.

- Stress testing to assess the strength and durability of the bent glass.

9. What are common troubleshooting techniques for glass bending issues?

Troubleshooting techniques for glass bending issues include:

- Adjusting the bending temperature or pressure.

- Using different molds or bending equipment.

- Annealing the glass after bending to relieve stress.

- Identifying and addressing the root cause of the issue, such as glass defects or equipment malfunctions.

10. What are the latest advancements in glass bending technology?

Recent advancements in glass bending technology include:

- Automated bending machines for increased accuracy and efficiency.

- New glass compositions with improved bendability and strength.

- Innovative molding techniques for creating complex and customized shapes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass benders, also referred to as glassblowers, possess specialized skills in manipulating and shaping molten glass to create exquisite glass objects. Their meticulous craftsmanship extends to a range of tasks that are crucial to the production of unique and intricate glass pieces.

1. Material Preparation and Handling

Glass benders begin by meticulously preparing the raw materials, ensuring that the glass is of the highest quality. They select appropriate glass rods, tubes, and other components based on the desired design. Careful handling is paramount to prevent contamination or damage to the delicate materials.

- Inspect and prepare glass rods, tubes, and other raw materials.

- Ensure proper storage and handling of glass materials to maintain their integrity.

- Maintain a clean and organized workspace to facilitate efficient and safe operations.

2. Glass Melting and Manipulation

Utilizing specialized tools and techniques, glass benders skillfully melt the glass at controlled temperatures. They employ a combination of heat, blowing, and shaping to manipulate the molten glass, transforming it into the desired form. Precision and dexterity are essential in achieving the precise curves, angles, and dimensions required for each piece.

- Operate glass melting furnaces and control temperatures to achieve optimal glass fluidity.

- Use blowpipes, hand tools, and specialized equipment to shape and form molten glass.

- Apply various techniques, such as blowing, molding, and cutting, to create intricate designs and patterns.

3. Annealing and Finishing

Once the glass has been shaped, glass benders carefully anneal it to remove internal stresses and ensure its durability. This involves gradually cooling the glass in a controlled environment to prevent breakage. They also perform finishing touches, such as polishing, grinding, and decorating, to enhance the aesthetic appeal and functionality of the final product.

- Anneal glass objects by carefully controlling cooling rates to eliminate internal stresses.

- Polish, grind, and decorate glass pieces to achieve desired surface finishes and aesthetic enhancements.

- Inspect and ensure the quality of finished glass products before packaging and shipment.

4. Collaboration and Communication

Glass benders often work in collaborative environments, interacting with designers, engineers, and other professionals. They effectively communicate their ideas, provide technical insights, and contribute to the overall design and production processes. Strong communication skills enable them to convey complex concepts and instructions clearly.

- Collaborate with designers and engineers to translate design concepts into tangible glass products.

- Communicate technical information and provide guidance to other team members involved in production.

- Maintain open communication channels to ensure smooth operations and effective problem-solving.

Interview Tips

To ace an interview for a glass bender position, it is crucial to showcase your technical proficiency, passion for the craft, and ability to work effectively in a collaborative environment. Here are some tips to help you excel:

1. Research the Company and Industry

Demonstrate your interest in the company by thoroughly researching their history, values, and current projects. Familiarize yourself with the specific industry and its recent advancements to show that you are well-informed and eager to contribute.

- Visit the company’s website and social media pages.

- Read industry publications and attend relevant events.

- Network with professionals in the field.

2. Highlight Your Technical Skills

Emphasize your expertise in glass bending techniques, including melting, shaping, and annealing. Provide specific examples of projects you have worked on that showcase your proficiency in creating unique and intricate glass pieces. Be prepared to discuss the tools and equipment you are familiar with.

- Quantify your accomplishments to demonstrate the impact of your work.

- Be prepared to discuss your knowledge of different types of glass and their properties.

- Showcase your ability to follow instructions and work within specifications.

3. Showcase Your Passion and Creativity

Glass bending is an art form that requires passion and creativity. Express your enthusiasm for the craft and explain how you find inspiration in your work. Share examples of your personal projects or artistic endeavors that demonstrate your innovative and expressive abilities.

- Describe how you approach design challenges and find unique solutions.

- Discuss your interest in exploring new techniques and experimenting with different materials.

- Present a portfolio or online gallery of your work.

4. Emphasize Collaboration and Communication

Highlight your ability to work effectively in a collaborative team environment. Describe your experience in communicating technical information and collaborating with designers and engineers. Emphasize your willingness to contribute ideas and share knowledge with others.

- Discuss your experience in providing technical guidance to colleagues.

- Explain how you manage conflict and resolve problems in a team setting.

- Share examples of successful projects where you played a collaborative role.

5. Prepare Thoughtful Questions

Asking well-thought-out questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions that show you have researched the company and are eager to learn more about their specific projects, industry trends, and growth opportunities.

- Inquire about the company’s current projects and future plans.

- Ask about the company’s commitment to innovation and professional development.

- Express your interest in opportunities for growth and advancement within the organization.

Next Step:

Now that you’re armed with the knowledge of Glass Bender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Glass Bender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini