Are you gearing up for an interview for a Glass Tube Bender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Tube Bender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

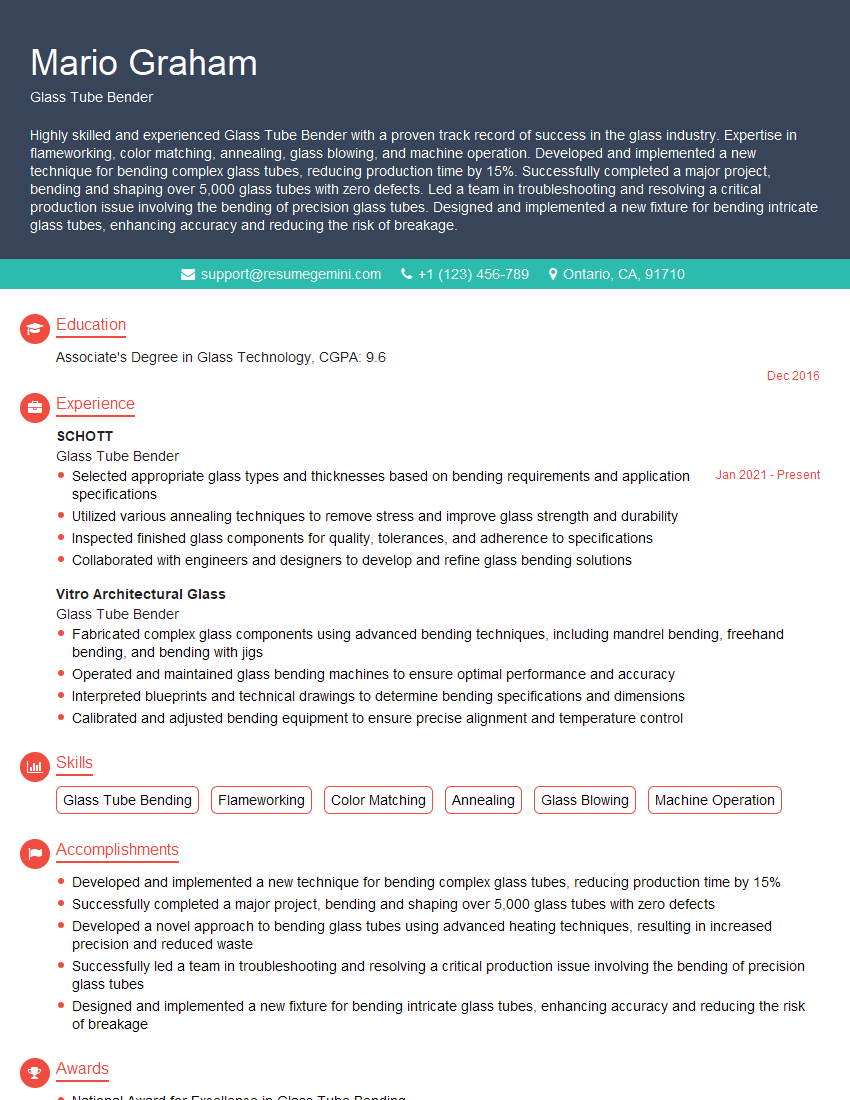

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Tube Bender

1. Describe the different types of glass used for tube bending and their properties?

There are various types of glass used for tube bending, each with its unique properties:

- Borosilicate glass: High thermal resistance, low expansion coefficient, and excellent chemical resistance.

- Soda-lime glass: Common type, low cost, but lower thermal resistance and higher expansion coefficient.

- Fused quartz: Extremely high thermal resistance, excellent optical properties, but more expensive.

- Lead glass: High refractive index, used for lenses and prisms, but less thermal resistant.

2. Explain the factors that influence the bend radius of a glass tube?

Factors affecting bend radius:

- Glass type: Different glasses have varying bending properties.

- Tube diameter: Thinner tubes have smaller bend radii.

- Wall thickness: Thicker walls require larger bend radii.

- Bending temperature: Higher temperatures allow smaller bend radii.

- Tooling: The shape and size of the bending tools influence the radius.

Additional factors:

- Glass condition: Annealed glass bends more easily than tempered glass.

- Bending speed: Slower speeds allow for more precise bending.

- Experience: Skilled benders can achieve tighter bend radii.

3. What are the common defects that can occur during glass tube bending and how can they be prevented?

Common defects include:

- Kinks: Sharp bends due to excessive force.

- Scratches: Damage to the glass surface from improper handling or tooling.

- Cracks: Overheating or improper cooling.

- Ovality: Non-circular cross-section caused by uneven heating.

Prevention measures:

- Use appropriate bending tools and techniques.

- Handle glass carefully to avoid scratches.

- Heat glass evenly and control cooling rate.

- Inspect tubes before and after bending to detect defects.

4. Describe the process of annealing glass tubes after bending?

Annealing involves controlled cooling to relieve internal stresses created during bending:

- Gradually cool the glass from the bending temperature to a lower temperature, typically around 500°C.

- Hold the glass at this temperature for a specific duration, allowing stresses to dissipate.

- Continue cooling the glass slowly to room temperature over several hours.

5. What are the safety precautions that must be taken when working with glass tube bending equipment?

- Wear appropriate PPE: Safety glasses, gloves, and protective clothing.

- Handle glass carefully: Use proper techniques to avoid cuts or breakage.

- Operate equipment safely: Follow manufacturer’s instructions and ensure equipment is well-maintained.

- Ventilate the workspace: Fumes from heating glass can be harmful.

- Dispose of waste glass properly: Sharp edges can cause injuries.

6. What is the difference between internal and external mandrel bending and when would you use each method?

Internal mandrel bending:

- Involves inserting a mandrel (support) into the glass tube before bending.

- Prevents the tube from collapsing or deforming during bending.

- Used for tight bends or complex shapes.

External mandrel bending:

- The glass tube is bent around an external mandrel without inserting a support.

- Suitable for larger bend radii and simple bends.

- Allows for easier access and manipulation during bending.

7. How do you measure the bend angle of a glass tube?

- Use a protractor or angle gauge to measure the angle between the two tangents to the tube at the bend.

- Alternatively, use a specially designed bending angle measurement tool.

- Ensure the measurement is accurate to achieve precise bending results.

8. What is the role of a fire polish in glass tube bending?

- Fire polishing involves heating the edges of the cut or bent glass to smooth and remove any sharp edges.

- It improves the appearance and safety of the glass tube by reducing the risk of cuts or splinters.

- Fire polishing also strengthens the glass and makes it more resistant to breakage.

9. How would you determine the optimal bending temperature for a specific type of glass?

- Refer to the manufacturer’s specifications or technical data sheets.

- Perform tests on small samples of the glass to determine the temperature range that produces the desired bending results.

- Consider the glass thickness, composition, and the intended bend radius.

- Start at a lower temperature and gradually increase it until the glass becomes pliable enough to bend without cracking or deforming.

10. What are the key characteristics of a good glass tube bending machine and how do they contribute to the bending process?

- Precise temperature control: Ensures consistent and accurate heating of the glass.

- Durable construction: Withstands the high temperatures and forces involved in bending.

- Ease of use: Operator-friendly controls and intuitive interface.

- Safety features: Protects the operator from heat, fumes, and glass fragments.

- Versatility: Capable of bending various glass tubes with different diameters and thicknesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Tube Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Tube Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Tube Benders are responsible for shaping and bending glass tubes to create various designs for scientific, laboratory, and industrial applications. Their key duties include:

1. Bending and Shaping Glass Tubes

Using specialized tools and techniques, Glass Tube Benders meticulously bend and shape glass tubes to precise angles and curvatures according to specifications and blueprints.

- Operate and maintain bending machines and equipment.

- Measure and cut glass tubes to required lengths and diameters.

2. Inspecting and Testing Products

Glass Tube Benders thoroughly inspect and test their products to ensure they meet quality standards and specifications.

- Conduct visual inspections and use measuring devices to verify accuracy.

- Test the strength and durability of glass products through various methods.

3. Maintaining Tools and Equipment

To ensure efficient and safe operations, Glass Tube Benders are responsible for maintaining and calibrating their tools and equipment.

- Clean, maintain, and adjust bending machines and related tools.

- Follow maintenance schedules and perform regular inspections.

4. Reading and Interpreting Technical Drawings

Glass Tube Benders rely on technical drawings and instructions to understand and execute design specifications.

- Analyze and interpret technical drawings and blueprints.

- Ensure accurate measurements and dimensions based on specifications.

Interview Tips

To ace an interview for a Glass Tube Bender position, candidates should consider the following tips:

1. Prepare for Technical Questions

Interviewers will likely ask technical questions about glass bending techniques, equipment, and industry standards.

- Review bending methods, equipment operation, and safety protocols.

- Study industry guidelines and specifications related to glass tubing.

2. Highlight Experience and Skills

Emphasize your hands-on experience in glass bending, inspection, and equipment maintenance.

- Quantify your accomplishments and provide specific examples.

- Showcase your proficiency in using specialized tools and machinery.

3. Demonstrate Attention to Detail

Glass Tube Benders must have a keen eye for detail and precision.

- Explain how you ensure accuracy in bending and measuring processes.

- Describe your approach to quality control and product testing.

4. Emphasize Safety Awareness

Working with glass materials requires adherence to safety protocols.

- Highlight your understanding of safety regulations and proper handling techniques.

- Discuss your experience in using personal protective equipment and maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Tube Bender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.