Are you gearing up for a career in Neon Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Neon Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

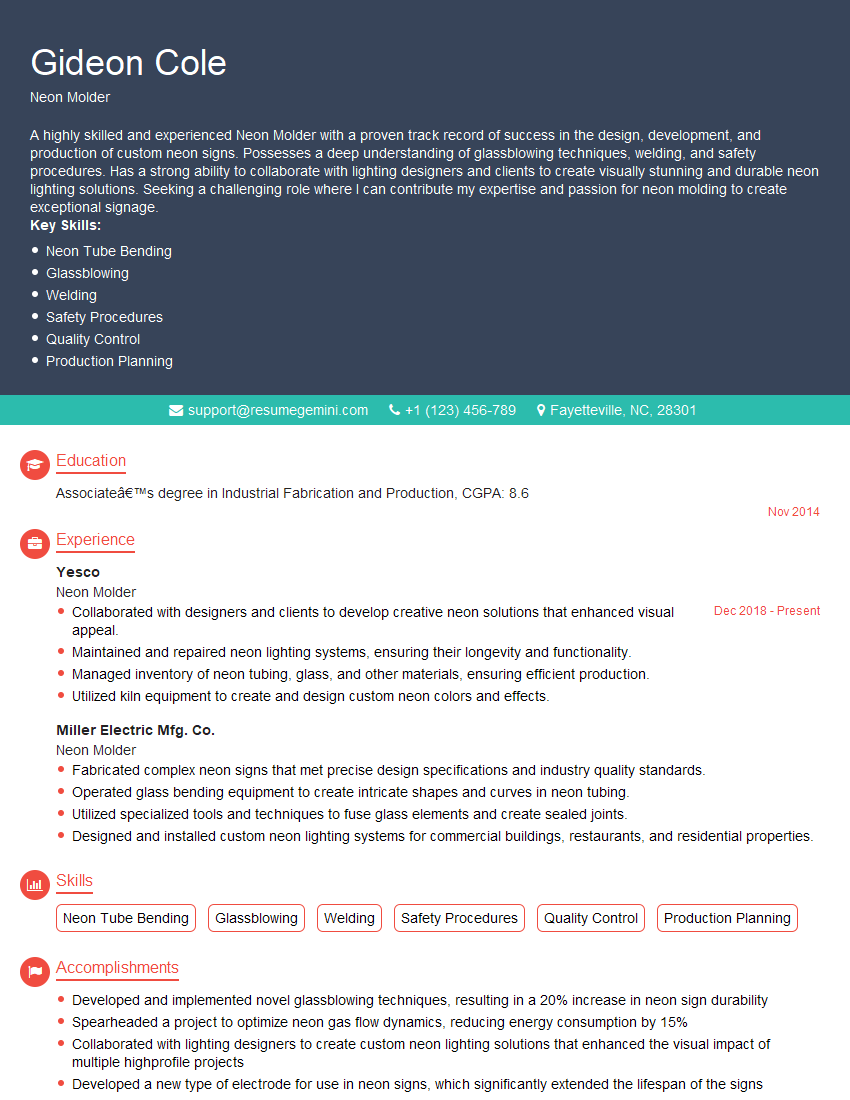

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Neon Molder

1. Explain the process of neon molding in detail.

Answer:

- Pattern Design: The first step is to create a pattern or mold of the desired neon design using sheet metal or plastic.

- Glass Tube Preparation: Pre-cut glass tubes are cleaned and sealed at one end for gas filling.

- Gas Filling: The tubes are filled with a neon gas mixture, typically containing neon, argon, and other gases to achieve the desired color.

- Bending and Shaping: The filled glass tubes are then heated and bent into the desired shape according to the pattern.

- Electrode Attachment: Electrodes are attached to the ends of the tubes to allow electrical current to flow.

- Testing and Installation: Once assembled, the neon signs are tested and undergo a vacuum check to ensure proper operation before installation.

2. What are the different types of glass used in neon molding?

- Soda-lime glass: Commonly used for its clarity and cost-effectiveness.

- Borate glass: Known for its high temperature resistance and ability to hold complex shapes.

- Lead glass: Known for its heavy weight, durability, and high refractive index.

3. Discuss the factors that affect the color of neon signs.

Answer:

- Gas Mixture: The combination of gases used to fill the tubes determines the primary color of the neon sign.

- Glass Tint: The type of glass and any applied tint can affect the color and opacity of the light.

- Electrode Material: The material used for the electrodes, such as tungsten or nickel, can influence the color.

4. Describe the safety measures to be followed while working with neon molding equipment.

Answer:

- Electrical Safety: Ensure proper grounding and protection against electrical shocks.

- Glass Handling: Wear gloves and safety glasses to prevent cuts from broken glass.

- Gas Safety: Work in well-ventilated areas to avoid inhalation of toxic gases.

- Heat Precautions: Use heat-resistant gloves and tools to handle hot glass tubes.

- Eye Protection: Wear safety glasses to protect eyes from UV radiation emitted by neon signs.

5. Explain the role of a vacuum pump in neon molding.

Answer:

- Creating a Vacuum: The vacuum pump removes air from the glass tubes before filling them with neon gas.

- Maintaining a Vacuum: The vacuum helps prevent impurities from entering the tubes and compromising the neon gas mixture.

- Pressure Control: The vacuum pump allows for precise control of the pressure inside the tubes during the gas filling process.

6. Describe the process of electrode attachment in neon molding.

Answer:

- Preparation: Clean the ends of the glass tubes and the electrodes thoroughly.

- Flux Application: Apply a flux paste to the cleaned surfaces to improve electrical conductivity.

- Soldering: Use a high-temperature soldering iron to solder the electrodes to the tube ends.

- Cooling and Inspection: Allow the solder joints to cool and inspect them for proper connection.

7. What are the benefits of using colored glass in neon molding?

Answer:

- Enhanced Aesthetics: Colored glass allows for a wider range of visual effects and customization.

- Color Stability: Colored glass is less likely to fade or discolor over time than painted or coated glass.

- Increased Durability: Colored glass is more durable and less prone to scratches or damage.

8. Describe the troubleshooting process for a neon sign that is not illuminating.

Answer:

- Power Supply: Check if the power supply is providing proper voltage to the sign.

- Gas Leak: Look for cracks or leaks in the glass tubes that may cause a loss of neon gas.

- Electrode Connections: Inspect the electrode connections to ensure they are securely attached and not damaged.

- Glass Tube Damage: Examine the glass tubes for any breaks or damage that may affect the electrical current flow.

9. What are the maintenance requirements for neon signs?

Answer:

- Regular Cleaning: Clean the neon signs regularly to remove dust and debris that can affect light output.

- Transformer Inspection: Regularly check the transformer for any signs of wear or damage.

- Gas Fill Monitoring: Monitor the gas pressure in the tubes and refill them as needed to maintain optimal brightness.

- Electrode Cleaning: Clean the electrodes periodically to prevent oxidation and ensure proper electrical conductivity.

10. Discuss the environmental impact of neon molding and how to minimize it.

Answer:

- Gas Emissions: Neon gas is a greenhouse gas, and its release into the atmosphere can contribute to climate change.

- Energy Consumption: Neon signs can be energy-intensive, especially when they are used for extended periods.

- Waste Management: Disposing of old or damaged neon signs can pose environmental challenges due to the presence of hazardous materials.

- Use energy-efficient neon signs.

- Recycle old or damaged neon signs responsibly.

- Use sustainable materials in the manufacturing process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Neon Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Neon Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Neon Molders are skilled artisans who shape molten glass into custom-designed neon signs and light fixtures. They work closely with designers and clients to create eye-catching visual displays that meet specific requirements. Key responsibilities include:

1. Neon Tube Fabrication

Bend and shape neon tubing according to design specifications.

- Use specialized tools to manipulate glass tubing

- Ensure precision and accuracy in tube bending

2. Gas Filling and Sealing

Fill neon tubes with the appropriate gases and seal them to maintain pressure.

- Calculate gas volume and pressure requirements

- Use vacuum pumps and sealing equipment to process tubes

3. Electrical Wiring and Assembly

Connect electrical components to neon tubes and assemble finished products.

- Install transformers, power cords, and switches

- Test electrical circuits for proper functionality

4. Finishing and Installation

Polish and clean neon signs, ready them for installation, and mount them on surfaces.

- Apply protective coatings and finishes

- Coordinate with clients and contractors for proper installation

5. Maintenance and Repair

Maintain and repair existing neon signs as needed.

- Diagnose and fix electrical issues

- Replace damaged neon tubes and components

Interview Tips

To ace an interview for a Neon Molder position, it’s crucial to highlight your technical skills, attention to detail, and ability to work under pressure. Consider the following tips:

1. Research the Industry and Company

Familiarize yourself with the neon molding industry, the latest techniques and trends, and the specific company you’re applying to. This shows your interest and commitment.

2. Practice Your Skills

Showcase your expertise by bringing a portfolio of your previous work or providing examples of your neon molding abilities. This will give the interviewer a tangible demonstration of your skills.

3. Prepare for Technical Questions

Expect questions about gas filling, electrical wiring, and troubleshooting techniques. Review relevant concepts and be ready to explain your knowledge in detail.

4. Emphasize Attention to Detail

Neon molding requires a high level of precision and accuracy. Highlight your attention to detail and meticulous approach in your answers and examples.

5. Showcase Problem-Solving Abilities

Demonstrate your ability to solve problems and adapt to unexpected situations. Discuss past experiences where you encountered challenges in neon molding and how you overcame them.

6. Highlight Your Passion

Express your enthusiasm for the neon molding craft and explain why you’re passionate about creating unique and eye-catching visual displays.

7. Ask Thoughtful Questions

Asking thoughtful questions shows your engagement and curiosity. Prepare questions about the company’s projects, industry outlook, or opportunities for professional growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Neon Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.