Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stone Fabricator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

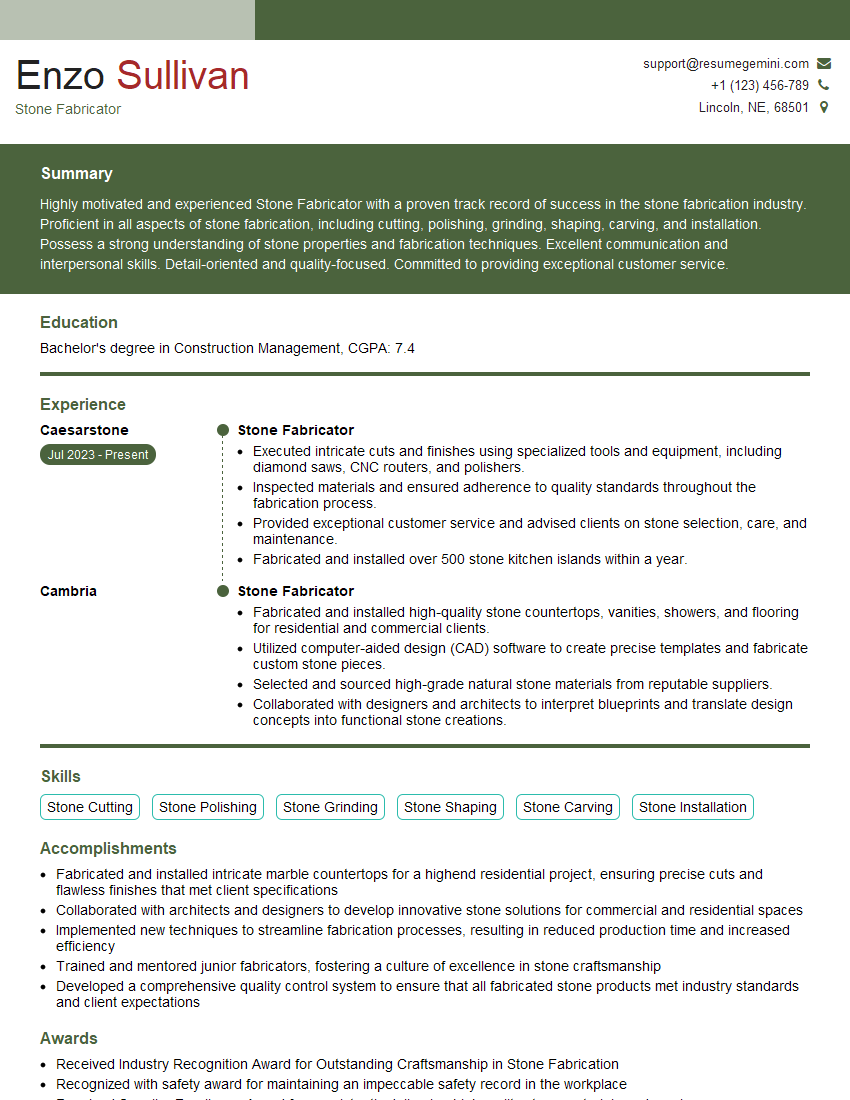

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stone Fabricator

1. What are the different types of stone fabrication methods you are familiar with?

- CNC machining: using computer-controlled machines to cut and shape stone

- Waterjet cutting: using a high-pressure stream of water to cut through stone

- Laser cutting: using a laser beam to cut through stone

- Diamond wire sawing: using a wire coated with diamond grit to cut through stone

- Hand carving: using hand tools to shape and cut stone

2. What are the different types of stones you have worked with and how do you determine the best fabrication method for each type?

Considerations for selecting fabrication method:

- Stone hardness and durability

- Desired finish and precision

- Production volume and budget

Experience with different stone types:

- Granite: Hard and durable, suitable for CNC machining, waterjet cutting, and laser cutting

- Marble: Softer and more delicate, requires careful handling and often hand carving or waterjet cutting

- Limestone: Medium hardness, suitable for CNC machining, waterjet cutting, and diamond wire sawing

- Sandstone: Soft and porous, often hand carved or processed using waterjet cutting

- Slate: Natural cleavage planes, suitable for splitting and hand carving

3. How do you ensure the accuracy and precision of your stone fabrications?

- Using calibrated and maintained equipment

- Creating detailed templates and drawings

- Performing quality control checks throughout the fabrication process

- Measuring and verifying dimensions against specifications

- Employing experienced and skilled fabricators

4. What are the common challenges you face when fabricating stone and how do you overcome them?

- Stone defects or inconsistencies

- Complex or intricate designs

- Tight deadlines

- Safety concerns

- Thoroughly inspecting stone before fabrication

- Using appropriate fabrication methods and tools

- Planning and scheduling effectively

- Following proper safety protocols

Challenges:

Overcoming strategies:

5. Describe your process for creating custom stone pieces, from design concept to final installation.

- Consultation with client to understand requirements

- Developing design concepts and creating drawings

- Selecting appropriate stone materials

- Fabricating stone pieces to specifications

- Installing stone pieces on-site (if applicable)

- Ensuring customer satisfaction with final product

6. What are your strengths and weaknesses as a stone fabricator?

Strengths:

- Skilled in various fabrication techniques

- Strong attention to detail and accuracy

- Ability to work independently and as part of a team

- Excellent communication and problem-solving skills

Weaknesses:

- May need additional training on specialized equipment

- Working under tight deadlines can sometimes be challenging

7. What safety precautions do you take when working with stone?

- Wearing appropriate personal protective equipment (PPE)

- Using machinery safely and following operating procedures

- Properly storing and handling stone materials

- Maintaining a clean and organized work area

- Being aware of potential hazards and taking necessary precautions

8. What techniques do you use to achieve different finishes on stone surfaces, such as polished, honed, or textured?

- Using abrasive pads or powders to create a smooth and glossy surface

- Using abrasive pads or stones to create a matte and non-reflective surface

- Using specialized tools or techniques (e.g., sandblasting, bush hammering) to create a rough or textured surface

Polished finish:

Honed finish:

Textured finish:

9. How do you handle repairs or modifications to existing stone installations?

- Assessing the damage or modification requirements

- Determining the most appropriate repair or modification technique

- Matching stone materials and finishes to ensure seamless integration

- Performing repairs or modifications with precision and attention to detail

- Ensuring customer satisfaction with the final result

10. What are the latest trends and advancements in stone fabrication technology?

- Increased use of CNC machines and automation

- Development of new and innovative fabrication techniques

- Use of sustainable and eco-friendly materials and processes

- Integration of design software and 3D modeling

- Emphasis on creating unique and customized stone pieces

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stone Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stone Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stone Fabricators give shape to stone materials, using various tools and machinery to create countertops, tiles, and other stone products for residential and commercial applications. Here are the key job responsibilities of a Stone Fabricator:

1. Measuring and Cutting Stone

Using measuring tools, accurately measure and mark stone slabs to determine cutting lines. Employ specialized saws and equipment to cut stone according to the specified dimensions and shapes.

2. Shaping and Finishing Stone

Operate grinders and other shaping tools to refine stone edges and create intricate designs. Utilize polishing machines to achieve a smooth, lustrous finish on stone surfaces.

3. Installing Stone Products

Install fabricated stone products, such as countertops, tiles, and wall cladding, in accordance with established building codes and industry standards. Ensure proper alignment, leveling, and securing of stone components.

4. Maintaining Equipment and Workspace

Maintain and calibrate saws, grinders, and other equipment to ensure optimal performance and safety. Keep the work area clean and organized, adhering to established health and safety protocols.

5. Collaborating with Clients

Understand client needs and preferences. Provide guidance on stone selection, design options, and maintenance practices. Maintain open communication throughout the project to ensure satisfaction.

Interview Tips

To ace an interview for a Stone Fabricator position, consider the following tips and strategies:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and reputation. Learn about industry trends and innovations related to stone fabrication.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in using stone fabrication tools and machinery. Showcase your ability to interpret blueprints and follow specifications precisely. Provide examples of your attention to detail and commitment to quality.

3. Demonstrate Physical Strength and Endurance

Stone fabrication involves physically demanding tasks. Convey your physical fitness and ability to work in a fast-paced, hands-on environment.

4. Prepare for Technical Questions

Anticipate technical questions about stone types, fabrication techniques, and industry standards. Prepare clear and concise answers that demonstrate your knowledge and expertise.

5. Ask Informed Questions

During the interview, ask insightful questions that show your interest and engagement. Inquire about the company’s growth plans, safety protocols, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stone Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!