Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Laboratory Apparatus Glass Blower position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

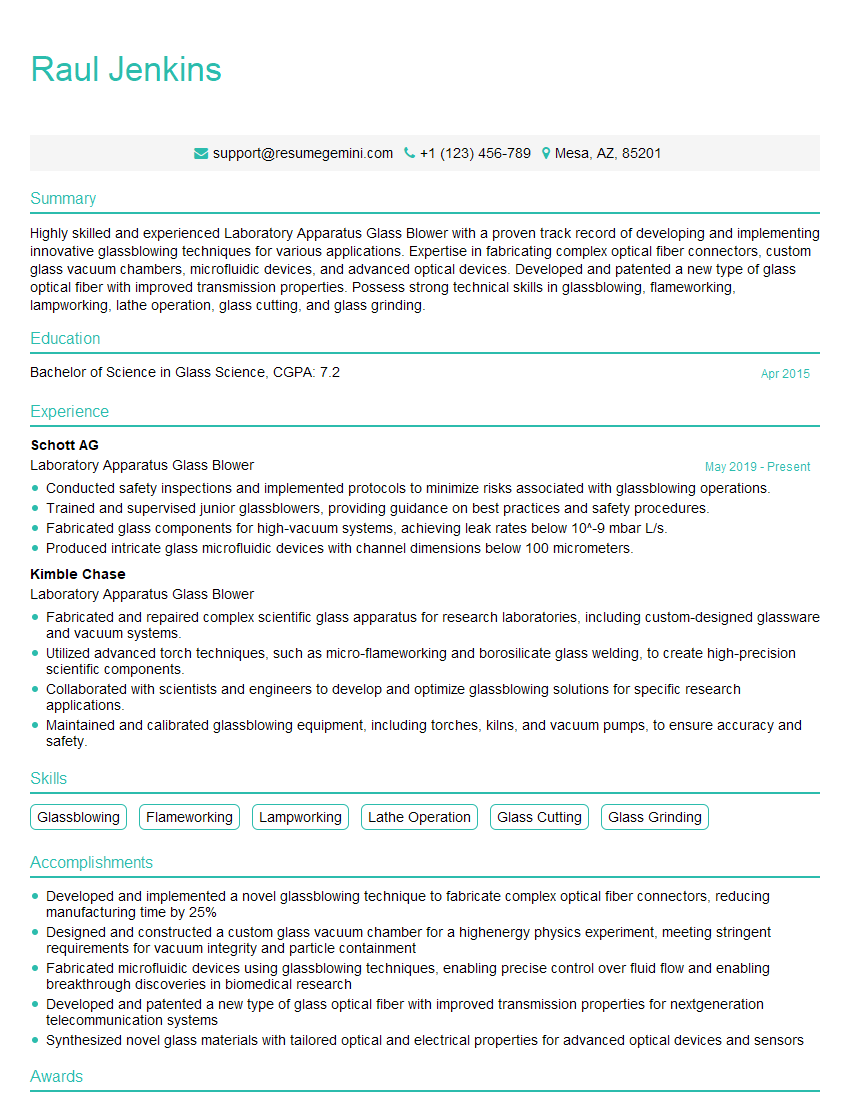

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laboratory Apparatus Glass Blower

1. What are the key principles of glass blowing?

- Keeping the glass at the appropriate temperature

- Using the right amount of pressure

- Creating the desired shape using the correct tools and techniques

2. Describe the steps involved in creating a basic glass apparatus, such as a test tube.

Gathering the Materials

- The type of glass required

- Tools such as a blowpipe, torch, and mandrel

Heating the Glass

- Using a torch to heat the glass until it becomes pliable

- Rotating the glass to ensure even heating

Shaping the Glass

- Using tools to shape the glass into the desired form

- Blowing into the glass to create the desired shape and size

Annealing the Glass

- Cooling the glass slowly to relieve any stress and increase its strength

- Placing the glass in an annealing oven or kiln

3. What are the different types of glassblowing torches and how do you choose the right one for a specific task?

- Oxygen-gas torches: Provide a high temperature flame for precise and delicate work

- Air-gas torches: Less expensive and easier to use, but produce a lower temperature flame

- Natural gas torches: Offer a wide range of flame temperatures and are suitable for larger projects

- Propane torches: Portable and versatile, but produce a lower temperature flame

- Mapp gas torches: Provide a hotter flame than propane and are ideal for thicker glass

4. What are the common defects that can occur in glassblowing and how do you prevent them?

- Annealing cracks: Caused by uneven cooling, can be prevented by using a controlled annealing process

- Cordiness: Caused by impurities in the glass, can be prevented by using high-quality glass

- Strain: Caused by uneven heating or cooling, can be prevented by using a controlled heating and cooling process

- Bubbles: Caused by trapped air, can be prevented by using a degassing process

- Cold shuts: Caused by incomplete fusion of the glass, can be prevented by using a hot enough flame and proper welding techniques

5. What are the safety precautions that must be taken when working with glassblowing equipment?

- Always wear appropriate safety gear, including gloves, eye protection, and a lab coat

- Work in a well-ventilated area to avoid inhaling fumes

- Handle hot glass with care and use heat-resistant tools

- Never point the torch at yourself or others

- Be aware of the location of fire extinguishers and safety showers

6. What are the different types of glassblowing tools and how do you use them?

- Blowpipes: Used for blowing air into the glass to create hollow forms

- Torches: Used for heating the glass to make it pliable

- Mandrels: Used for shaping and supporting the glass while it is being worked

- Paddles: Used for shaping and flattening the glass

- Tweezers: Used for handling small pieces of glass

7. How do you troubleshoot common problems that can occur while glassblowing?

- Glass is not melting: Check the torch tip and make sure it is clean and not clogged

- Glass is cracking: Heat the glass more slowly and evenly

- Glass is bubbling: Degas the glass before working with it

- Glass is not annealing properly: Allow the glass to cool slowly and evenly

- Glass is not the desired shape: Use the appropriate tools and techniques to shape the glass

8. What are the different techniques used in glassblowing and how do you choose the right technique for a specific project?

- Blowing: Used to create hollow forms

- Fusing: Used to join two pieces of glass together

- Marvering: Used to smooth and polish the surface of the glass

- Punting: Used to attach a glass object to a punty rod for support

- Pulling: Used to create thin rods or tubes of glass

9. What are the different types of glass that can be used for laboratory apparatus and what are their properties?

- Borosilicate glass: High resistance to thermal shock and chemicals, commonly used for laboratory glassware

- Fused quartz: Extremely high resistance to heat and chemicals, used for specialized laboratory applications

- Soda-lime glass: Common type of glass used for containers and windows, not as durable as borosilicate glass

- Aluminosilicate glass: High strength and low thermal expansion, used for specialized applications such as telescope mirrors

- Lead crystal glass: Contains lead oxide, giving it a high refractive index and brilliance, used for decorative glassware

10. What are the career advancement opportunities for a Laboratory Apparatus Glass Blower?

- Lead Glass Blower: Supervise other glass blowers and manage the production of laboratory glassware

- Glassblowing Instructor: Teach glassblowing techniques and principles to students

- Glassblowing Artist: Create unique and artistic glass pieces

- Research and Development: Develop new glassblowing techniques and materials

- Quality Control: Ensure that laboratory glassware meets quality standards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laboratory Apparatus Glass Blower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laboratory Apparatus Glass Blower‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Laboratory Apparatus Glass Blower designs, fabricates, and repairs specialized glassware for scientific research and industry. Their key responsibilities include:

1. Design and Fabrication

Collaborating with scientists and engineers to design and fabricate custom glassware.

- Creating detailed drawings and specifications for glassware.

- Selecting appropriate glass types and forming techniques for specific applications.

2. Repair and Maintenance

Repairing damaged or broken glassware, including vacuum systems and laboratory equipment.

- Identifying the cause of damage and developing repair strategies.

- Using specialized techniques, such as fusing, grinding, and polishing, to restore glassware to working condition.

3. Quality Control

Inspecting and testing glassware to ensure it meets specifications and quality standards.

- Performing dimensional measurements, pressure testing, and visual inspections.

- Maintaining records of inspection results and recommending improvements.

4. Training and Supervision

Training and supervising apprentices or assistants in glassblowing techniques and safety procedures.

- Demonstrating proper glassworking skills and educating on safety protocols.

- Monitoring progress and providing feedback to ensure proficiency.

Interview Tips

To ace the interview for a Laboratory Apparatus Glass Blower position, candidates should consider the following tips:

1. Research the Company and Role

Thoroughly research the company and the specific role to gain a deep understanding of their business, products, and industry.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in designing, fabricating, and repairing glassware.

- Provide specific examples of projects you have worked on and the techniques you employed.

- If you have worked in a similar industry, discuss how your knowledge and skills are transferable.

3. Demonstrate Your Passion for Glassblowing

Convey your passion for glassblowing and your interest in the field.

- Share your knowledge of different glass types, forming techniques, and industry advancements.

- Explain why you are excited about the prospect of working in this industry.

4. Prepare for Technical Questions

Be prepared to answer technical questions about glassblowing techniques, materials, and equipment.

- Review the fundamentals of glassblowing, such as different heating and forming methods.

- Research common types of glassware used in scientific research and industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Laboratory Apparatus Glass Blower role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.